10. Troubleshooting

WARNING!

Before troubleshooting, read and understand the

Service and Maintenance Safety on page 35.

Set the machine to a safe condition.

The following table lists some of the problems that you may

encounter and provides possible causes and solutions.

If you encounter a problem that is difficult to solve, even after

reading this information, please contact your local dealer, the

distributor, or Wallenstein Equipment. Before you call, please

have the serial number for your product handy.

To find the serial number on your machine, see Serial Number

Location on page 5.

For engine troubleshooting, see the engine manufacturer's

manual.

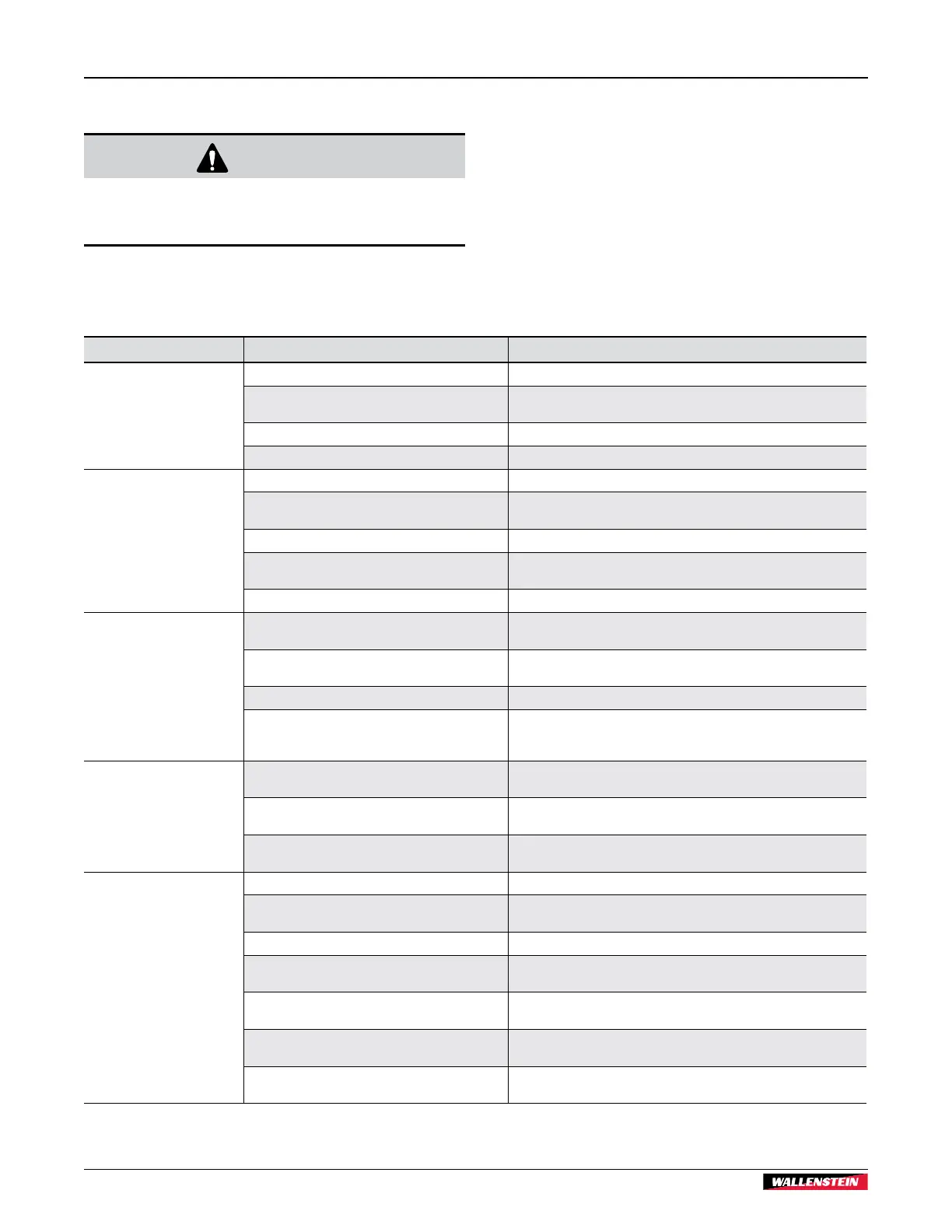

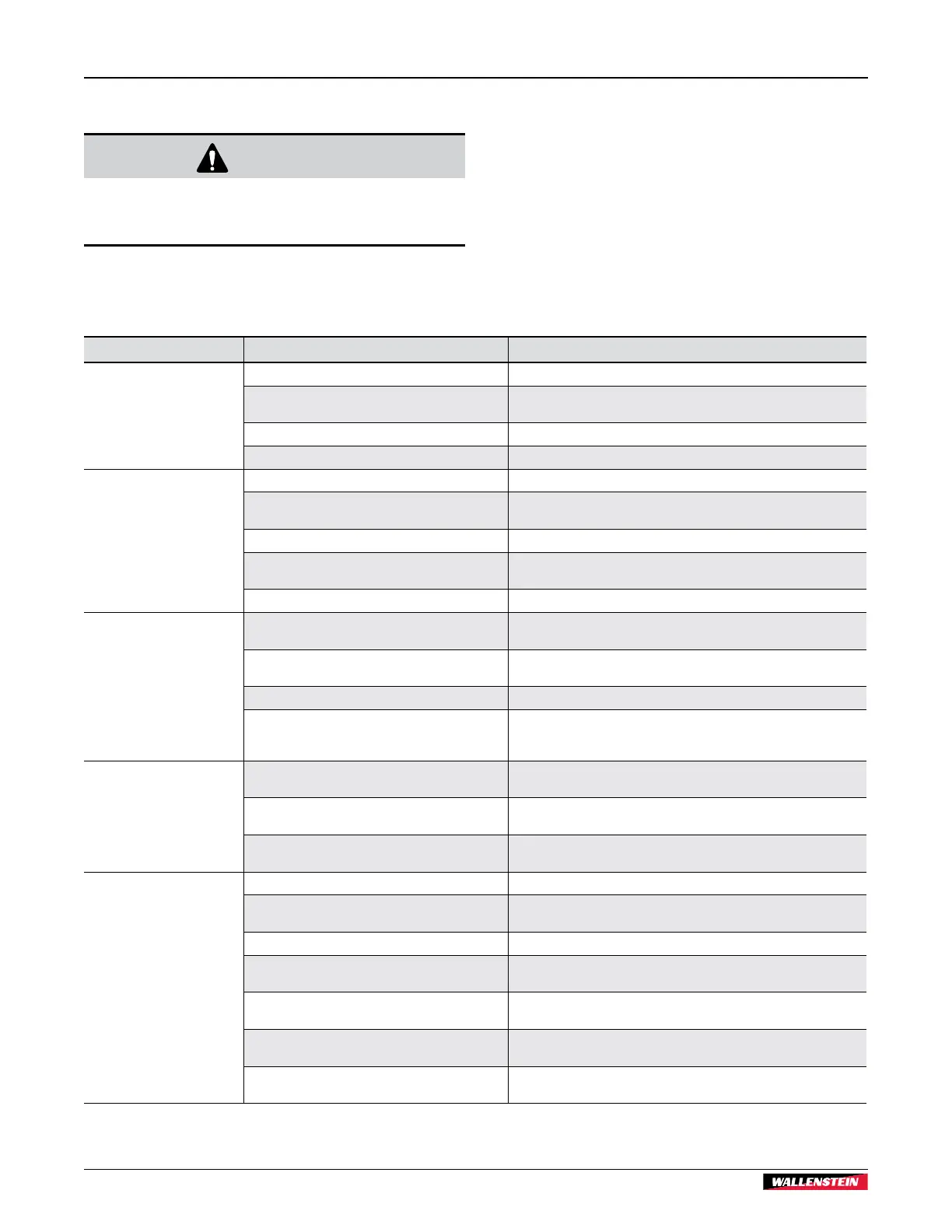

Problem Possible cause Solution

The rotor does not turn. The discharge chute is obstructed. Clear debris from the discharge chute.

The rotor is plugged. Inspect and clear the chipper infeed hopper, lower rotor housing,

and rotor.

The clutch is seized. Replace the clutch.

The drive belt is loose or broken. Set the tension or replace the drive belt.

Material is moving into

the machine too slowly.

The engine or rotor speed is too low. Make sure choke is off. Set throttle to increase rotor rpm.

The rotor knives, ledger knife, or shredder

knives are dull.

Rotate, sharpen, or replace the knives, as required.

The ledger knife clearance is incorrect. Set the ledger knife clearance.

A rotor knife edge angle is incorrect. Sharpen the two rotor knives to the specified 45° angle and make

sure that the knives are installed correctly.

The discharge chute is obstructed. Clear debris from the discharge chute.

There is unusual machine

vibration during operation.

A rotor knife is broken or missing. Check the rotor knives. Rotate, sharpen, or replace the knives, as

required.

The rotor may be bent. Check the rotor rotation to see if there is wobble. If the rotor

wobbles, replace the rotor.

The rotor bearings failed. Replace the rotor bearings.

Fasteners are loose. Use a calibrated torque wrench to tighten the fasteners to the

specified torque. For specifications, see Bolt Torque on page

48.

The mulch is too course. The chop block or twig breaker may be

damaged.

Inspect the chop block and twig breaker. If there is damage,

replace the component.

One or more shredder knives are broken or

missing.

Check the shredder knives. Sharpen or replace the knives, as

required.

Shredder knives are installed incorrectly. Check the shredder knife installation. Correct the installation, as

required.

The machine requires

excessive power or the

engine stalls.

The discharge chute is obstructed. Clear debris from the discharge chute.

The operator is feeding in too much material. Feed smaller amounts of material into chipper and/or shredder

hoppers.

The operator is feeding material in too quickly. Feed larger material slowly into the chipper hopper.

The rotor is plugged. Inspect and clear the chipper infeed hopper, lower rotor housing,

and rotor.

Green material does not discharge. Wait for the material to dry or alternate between placing dry and

wet material in the machine.

The ledger knife clearance is incorrect (too

large).

Set the ledger knife clearance.

The rotor knives, ledger knife, or shredder

knives are dull.

Rotate, sharpen, or replace the knives, as required.

Troubleshooting

BXMT3213

Trailer Chipper / Shredder

46

Loading...

Loading...