Page 10

1.4 Filling Loop

On all models, set the pressure to 1.0 bar when cold.

Special attention must be given to corrosion inhibitor concentrations where there

is a need to top up the system. See Section 1.5.

It is recommended to isolate all electricity supplies to the appliance before topping

up system pressure.

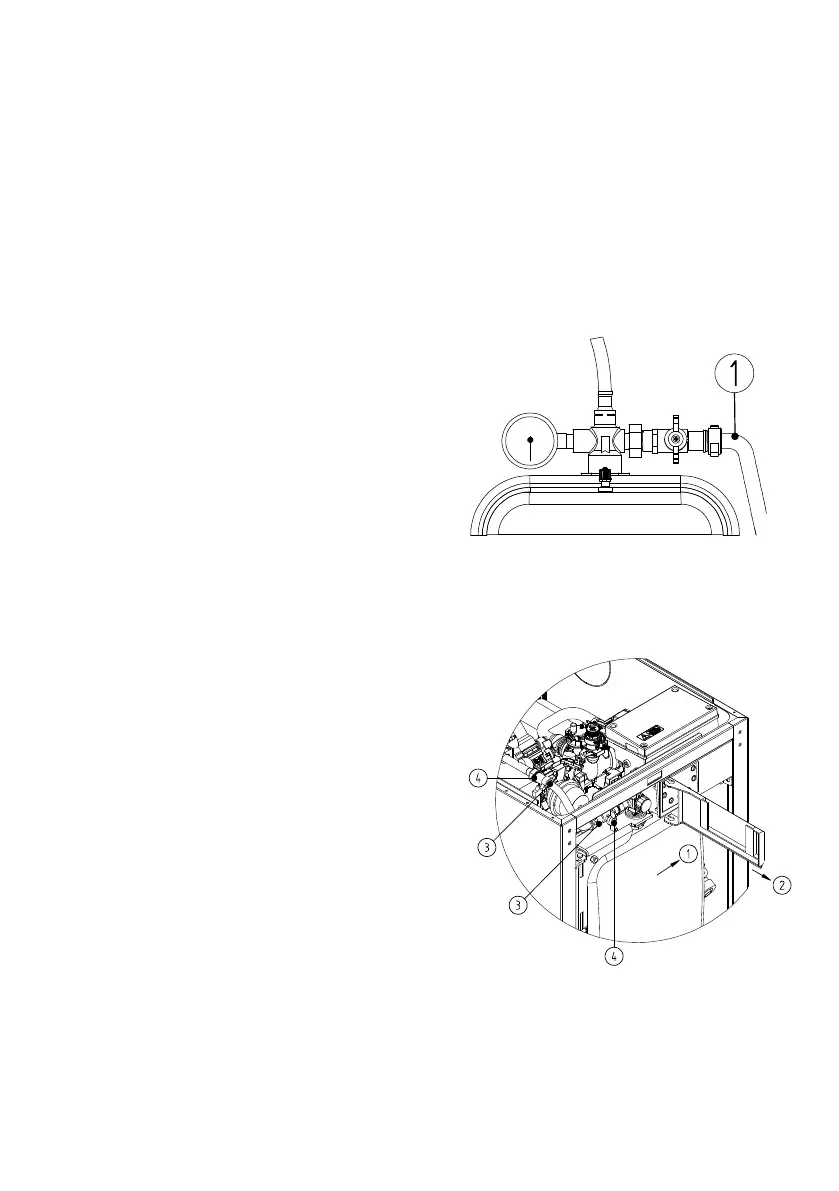

System Boilers – The filling loop is located above the expansion vessel.

Remove the dust caps, then fit the flexible hose (1) at both ends, open the valves

to increase system pressure.

Your installer will be able to advise the

position of the filling valve.

After topping up the system the valve(s)

must be fully closed and the flexible hose

disconnected from the valve(s), and dust

caps refitted.

Expect a small water loss from the hose.

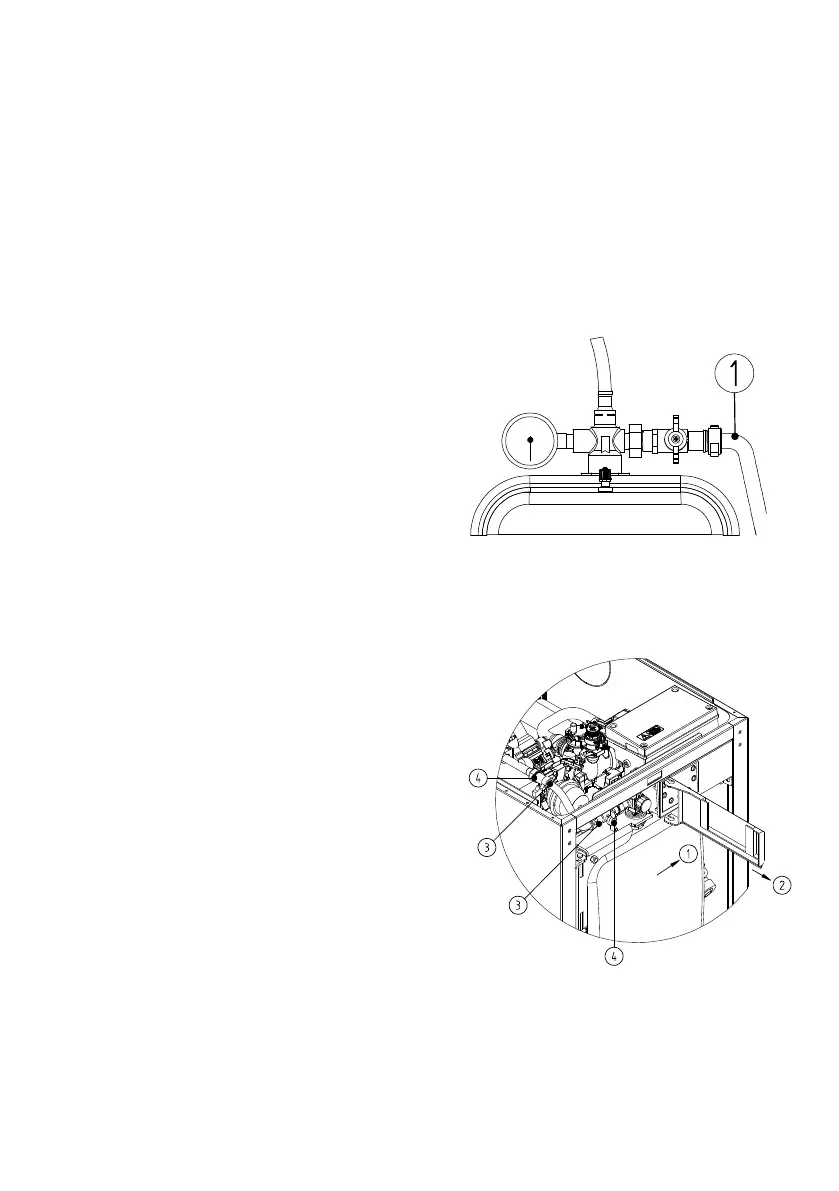

Combination Boilers – The filling loop is

accessed by opening (1) and removing (2)

the access cover.

Remove the dust caps, then fit the flexible

hose (3) at both ends, open the valves (4) to

increase system pressure.

After topping up the system the valve(s)

must be fully closed and the flexible hose

disconnected from the valve(s), and dust

caps refitted.

Expect a small water loss from the hose.

Loading...

Loading...