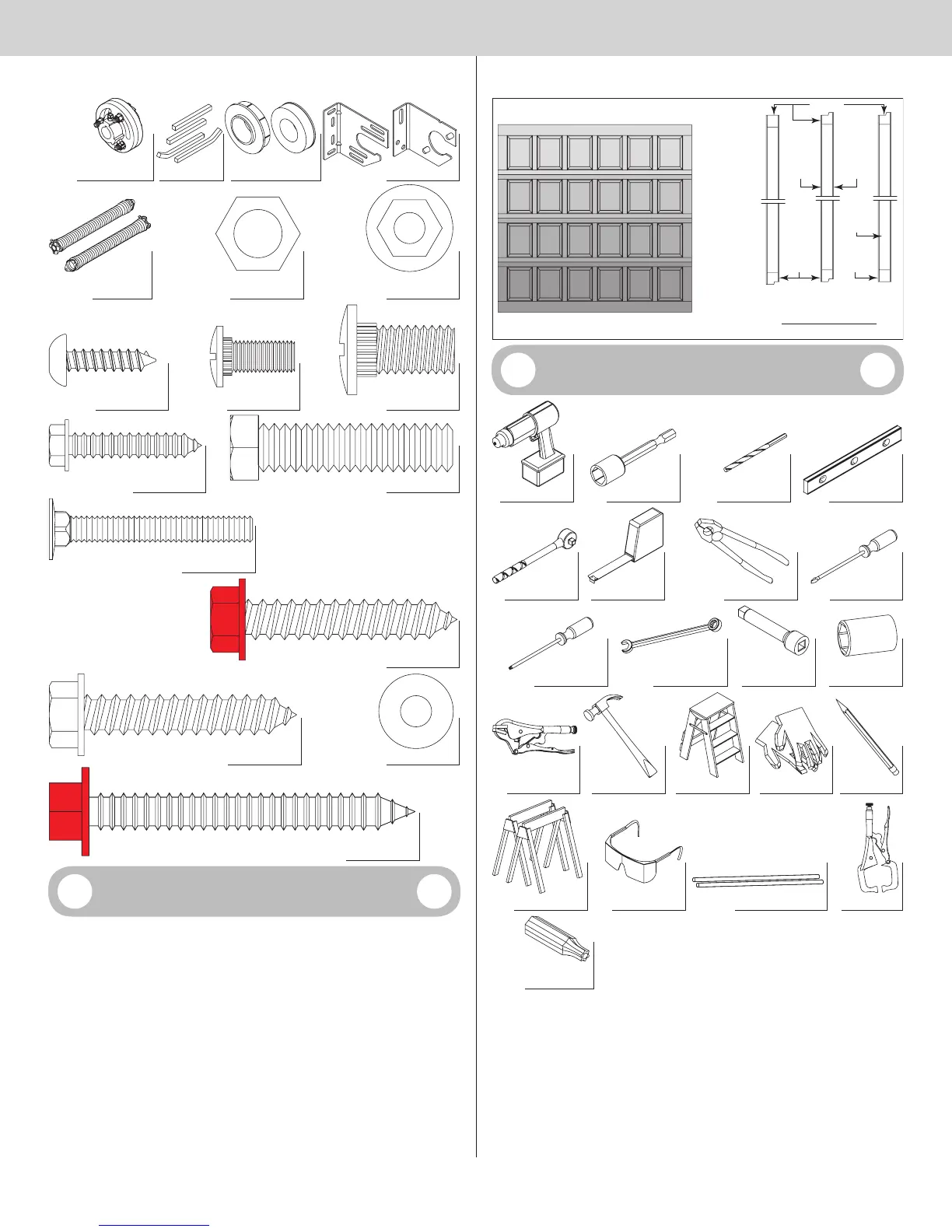

Center coupler

Keys

(as required)

Center bracket (as required)

Center bracket

bearing (as required)

1/4”- 20 Flanged

hex nuts (as required)

Torsion springs

RH/LH

3/8”- 16 Hex nuts

(as required)

3/8”-16 x 1-1/2” Hex bolts (as required)

1/4” - 14 x 1”

Lag screws (as required)

3/8”-16 x 3/4” Truss

head bolts (as required)

1/4”-20 x 9/16”

Track bolts (as required)

1/4” - 10 x 1”

Tamper-resistant

lag screw (as required)

1/4” - 20 x 1-7/8”

Carriage bolts (as required)

5/16” x 1-5/8” Hex head lag screws

5/16” x 1-5/8” Hex head lag screws

(as required)

Washer (as required)

5/16” x 2-1/2” Hex head lag screws

(RED HEAD) (as required)

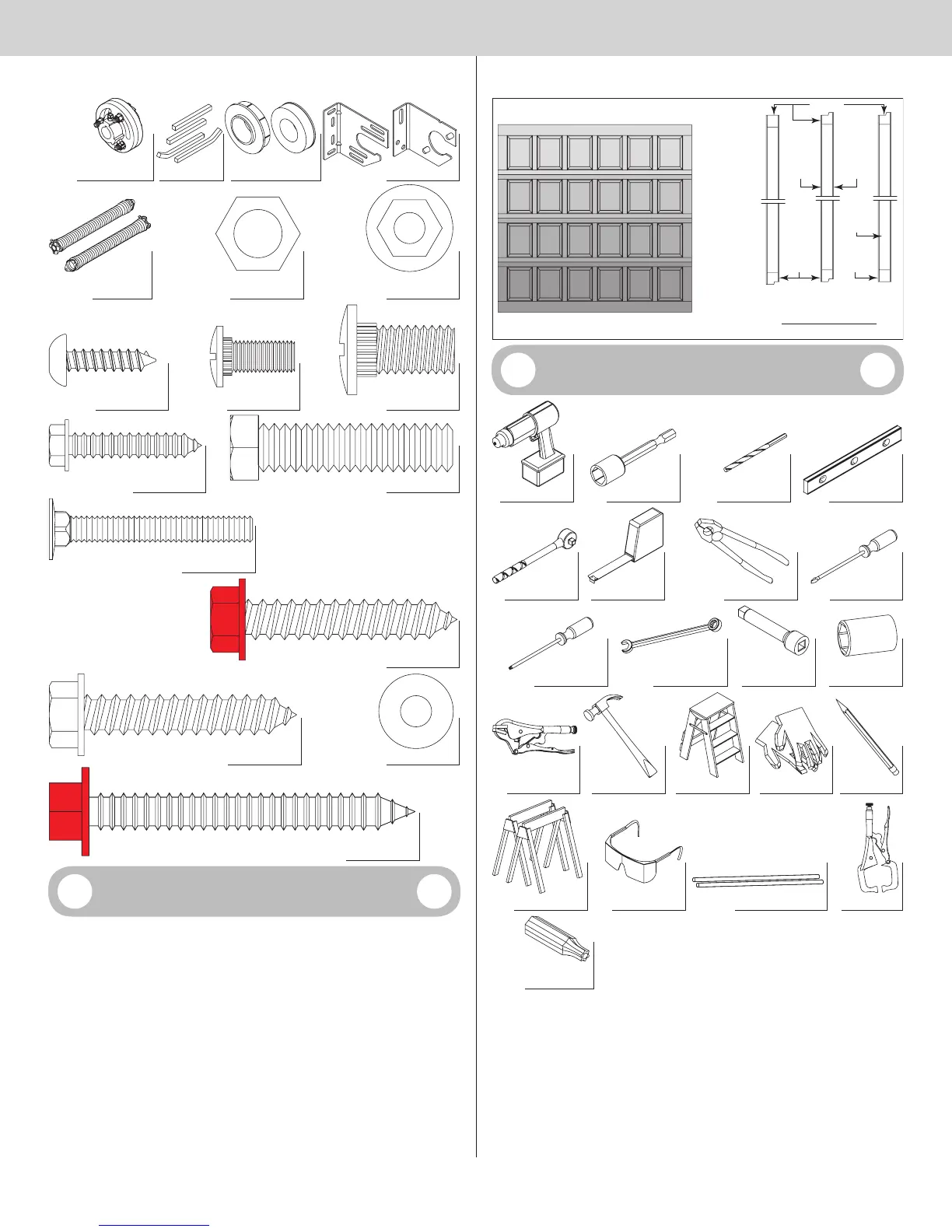

Door Section Identification

When installing your door, you must use sections of the appropriate height in the right stack-

ing location. Determine, what sections you need to use in what order depends on the design

of your door.

Sections are stamped for identification, #1, #2, #3, #4, #5, #6, and #7. The stamp, located

on each side of the sections identifies the stacking sequence. The sequence is always

determined by #1 being the bottom section to #6 or #7 being the highest top section. If the

stamp on the section is illegible, refer to the section side view illustration. The section side

view illustration shows the section profile of all sections, and can also be used to identify

each section.

The BOTTOM SECTION can be identified by #1.

The INTERMEDIATE I SECTION can be identified by #2.

The INTERMEDIATE II SECTION can be identified by #3, for a 4 section high door only.

The INTERMEDIATE III SECTION can be identified by #4, for a 5 section high door only.

The INTERMEDIATE VI SECTION can be identified by #5, for a 6 section high door only.

The INTERMEDIATE V SECTION can be identified by #6, for a 7 section high door only.

The TOP SECTION can be identified by a #, being the highest section.

Bottom

rail

Bottom

rail

Typical

stamping

location

Top rail

Typical design option “Outside surface of

door sections shown”

Bottom

section

Intermediate(s)Top

section

Side views of sections

Outside

surface

Inside

surface

1.

Bottom

section

2.

Intermediate I

section

3.

Intermediate II

section

4. or 3.

Top

section

## 1

NOTE: 3 Section high doors do not have an

Intermediate II Section.

Tools Required

Power drill Socket driver: 7/16” Level

Drill bits: 1/8”, 3/16”,

9/32”, 7/16”, 1/2”

Ratchet wrench Tape measure Pliers / Wire cutters Flat tip screwdriver

r

Wrenches: 3/8”, 7/16”,

3” Ratchet

extension

Sockets: 7/16”,

1/2”, 9/16”, 5/8”

Vise clamps Hammer Step ladder PencilLeather gloves

Locking pliersSafety glasses

Approved winding bars

Saw horses

t

4

Loading...

Loading...