11

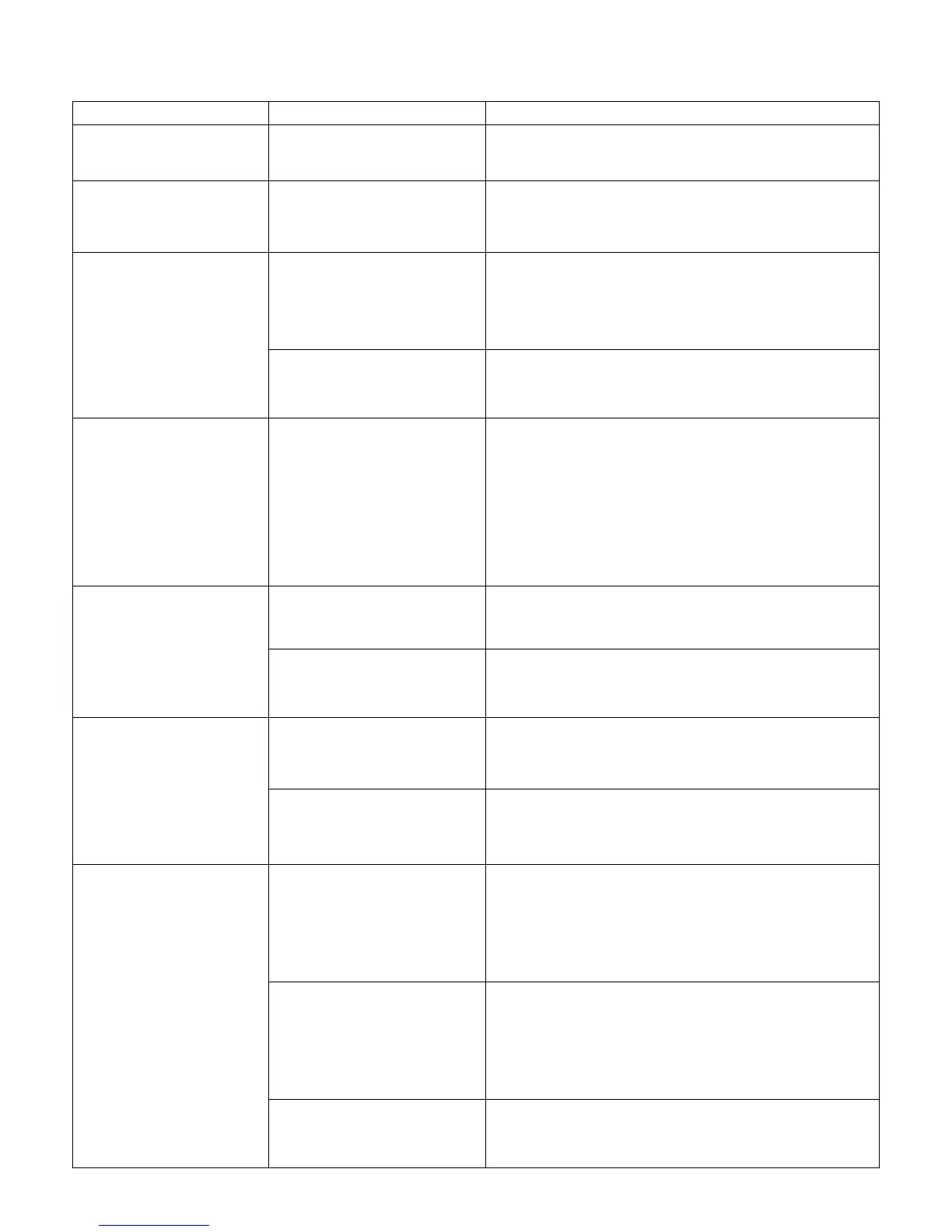

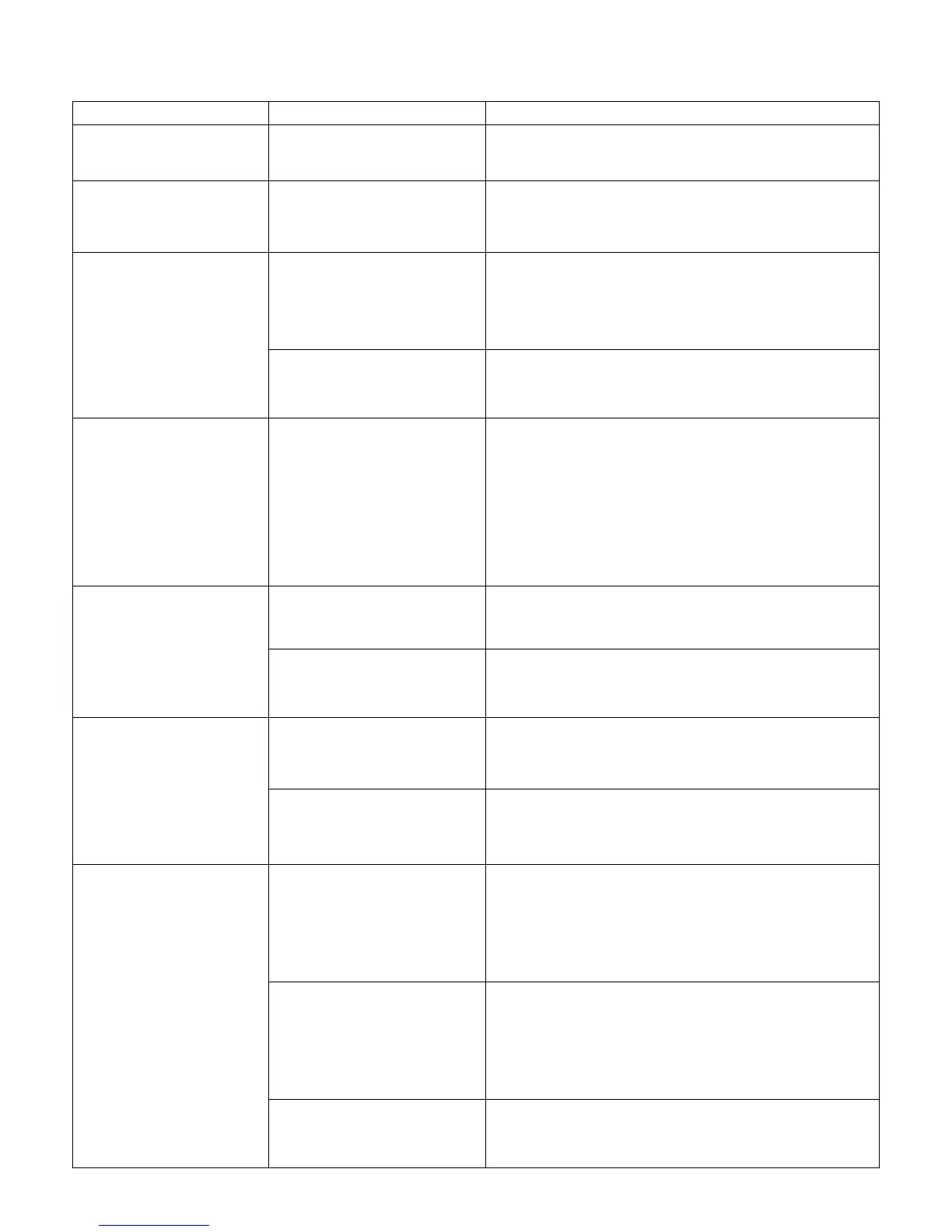

BURNER WILL LIGHT, BUT WILL NOT STAY LIT DURING “CALL FOR HEAT”

2. Check for line voltage at

the oil primary control

(120 volts)

3. Check R7284G or

R8184G indicator light,

(LED Screen if R7284P

control) with burner on,

call for heat.

R7284 or R8184 control is in

lockout. The R7284G &

R8184G control LED flashes for

½ seconds ON, ½ seconds

OFF. The R7284P control reads

“Lockout Mode”

Control is sensing bad flame signal, cad cell or

controller is defective, sees external light or

connections are shorted. Go to step 5.

The R7284P display reads

“Valve on Delay”

4. Applications with “valve

on delay”, verify that oil

valve is closed during

the “valve on delay”

period by opening view

port and verifying that

no flame is present

during 15 second “valve

on delay”

R7284P display still reads

“Valve on Delay”

If flame is present, replace valve.

5. Jumper oil primary T-T

terminals

Burner starts, and stays

running.

Trouble is in thermostat or limit circuit.

Burner starts, but doesn’t stay

running.

Disconnect line voltage and open thermostat or

limit switch.

Check all wiring connections

If burner does not stay running, go to step 6

6. Check that nozzle size

is per appliance

manufacturer

recommendation

Change nozzle and fuel pressure to factory settings

and retest, if burner doesn’t stay lit go to step 7

7. Check burner air band

setting is set up per

manufacturer

recommendation

Burner air band setting too low.

Could cause black puff of smoke on ignition if the

fuel-air mixture is too rich.

Use a combustion test kit to measure the CO

2

%

and smoke spot in the exhaust.

Adjust air band opening until CO

2

% measures

between 10-12 %, and smoke spot is a 1 or less.

If problem persists go to step 8

Burner air band setting too high

Could cause delayed ignition on start-up if the fuel-

air mixture is too lean.

Use a combustion test kit to measure the CO

2

%

and smoke spot in the exhaust.

Adjust air band opening until CO

2

% measures

between 10-12 %, and smoke spot is a 1 or less.

If problem persists go to step 8

Burner air band set at

manufacturers

recommendations

Loading...

Loading...