10

January, 2017

WE RECOMMEND THAT THE OPERATOR HAVE THE FOLLOWING TOOLS AVAILABLE WHEN MAKING ADJUSTMENTS OR

MAINTAINING THE MACHINE: METRIC ALLEN KEYS, METRIC SOCKET SET, METRIC WRENCHES, VOLTMETER, SCREW DRIVERS,

TAPE MEASURE, RULER, CALIPER, ADJUSTABLE WRENCHES AND A GREASE GUN.

ENSURE THAT THE MACHINE HAS BEEN TURNED OFF, LOCKED OUT / TAGGED OUT BEFORE PERFORMING

MECHANICAL ADJUSTMENTS.

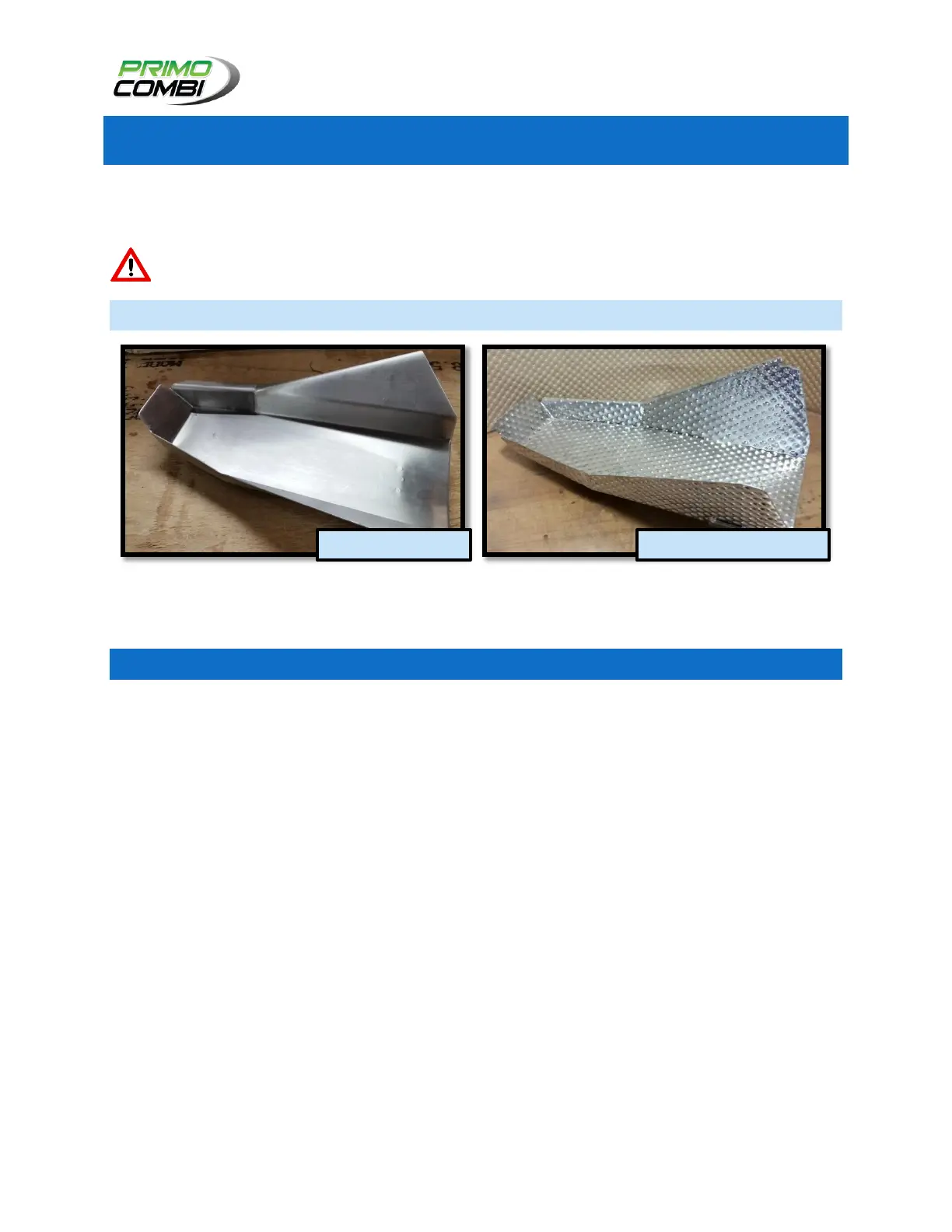

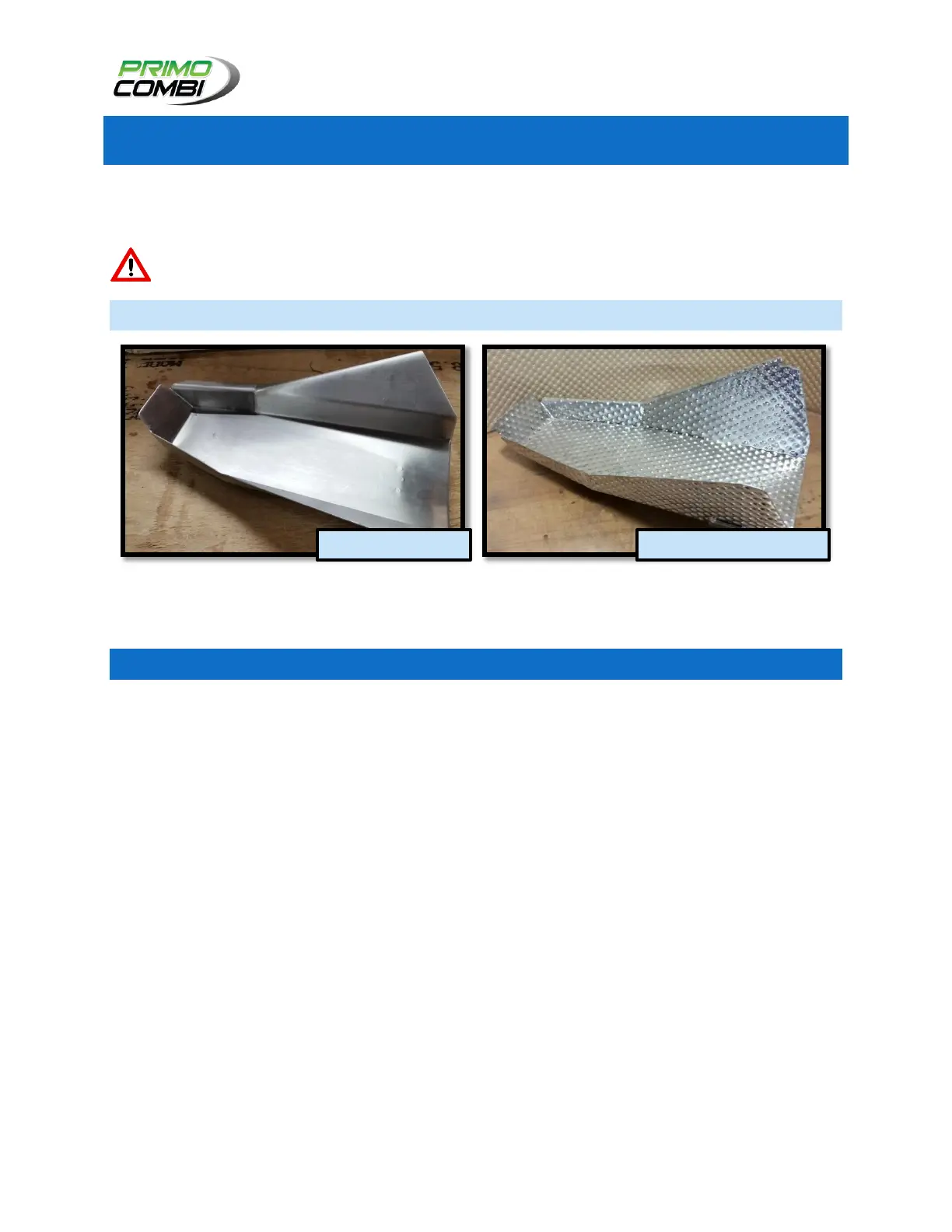

FOOD CONTACT PARTS

Stainless Steel food contact parts come in a variety of surface finish, depending on the application the

machine is designed for. Throughout this document there will be examples of multiple stainless steel

surface finishes.

TYPES OF FINISHES

1. The #4 surface finish is used for non-stick granular products.

2. Dimpled surfaces are used for product that has a tendency to stick to food contact parts.

3. 7DL surfaces are used for food contact parts that handle especially sticky product.

4. Mirror surface finishes are used for loose flowing powdery product that builds up on rougher

surfaces such as #4 finishes.

Loading...

Loading...