上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

30 Specialized, Concentrated, Focused

K_: number of repeats

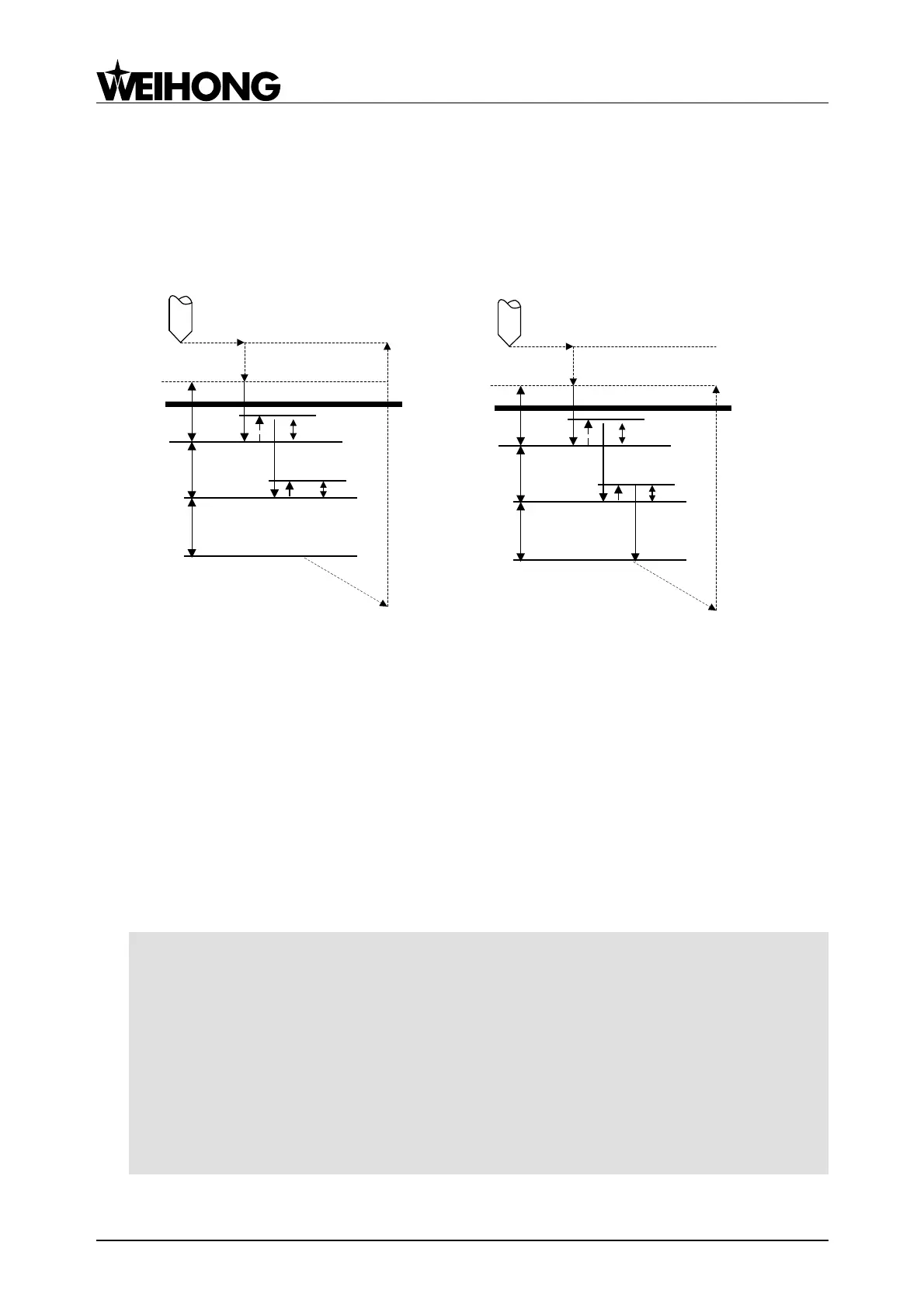

Hole-machining process is as shown in Fig. 4-19. It is easy to break and remove chips by

intermittent feeding in Z-axis. Q specifies each time cutting depth, and ―‖ is set by the parameter

(G73_G83 retract amount).

Point R

Q

Q

Q

Point Z

P

δ: Parameter setting

δ

δ

G98

(X,Y)

Initial Point

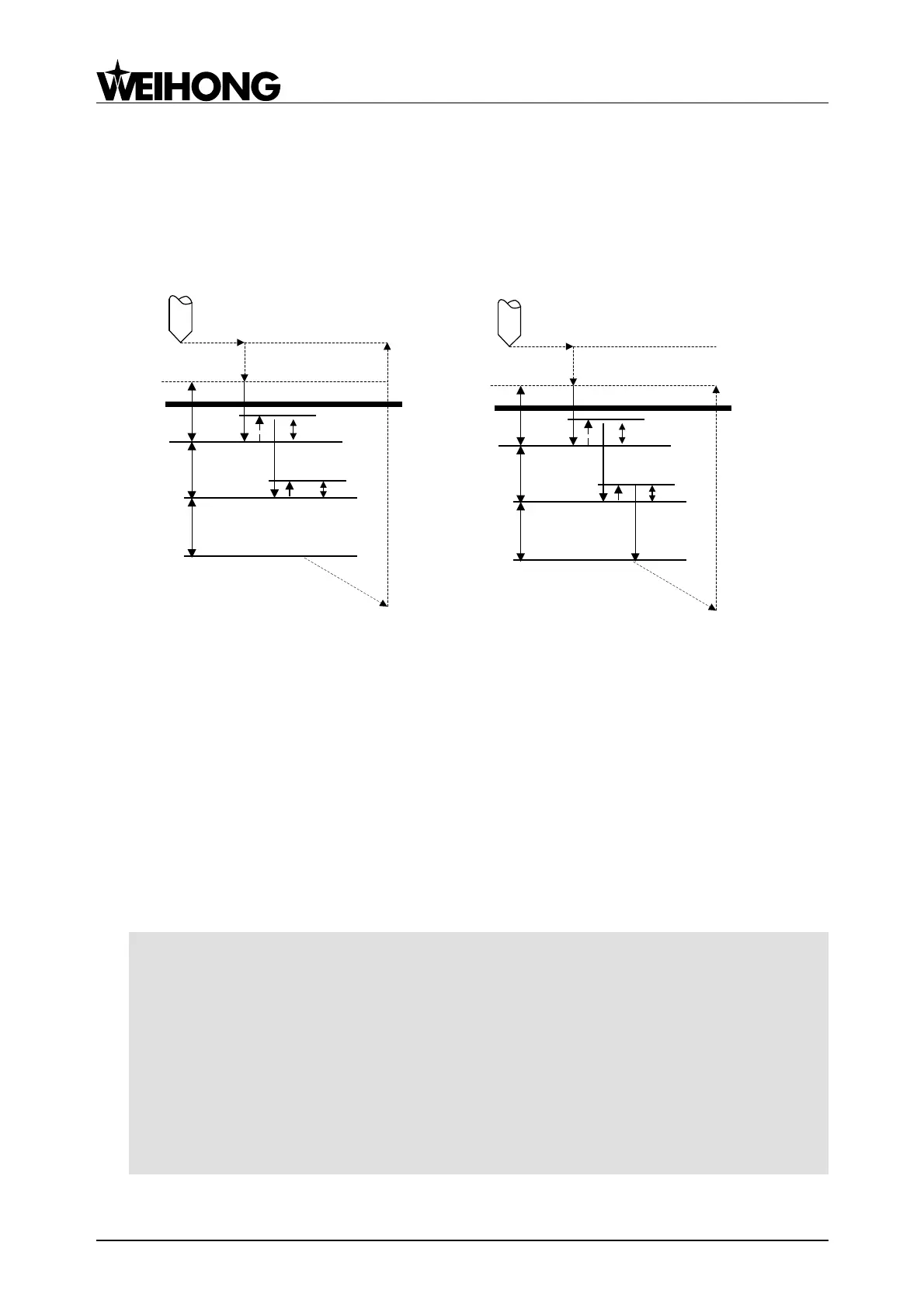

Point R

Q

Q

Q

Point Z

P

δ: Parameter setting

δ

δ

G99

(X,Y)

Initial Point

Fig. 4-19 G73 Machining Process

Process Description:

1. The cutter rapidly moves to the specified hole position (X, Y);

2. Moves to the appointed point R;

3. Moves down Q relative to the present drilling depth;

4. Rapidly moves upward retract distance (set by the parameter ―retract amount‖);

5. Repeats the above drilling operations until reaching point Z at the bottom of hole;

6. Returns to the initial point (G98) or R point (G99) at G00 speed;

Programming Example:

F1200. S600

M03 ’spindle CW on

G90

G00 X0. Y0. Z10. ’moving to the initial point.

G17

G90 G99

’Setting coordinates of point R, point Z and hole 1, with cutting depth each time as 2.0, and

drilling speed as 800

G73 X5. Y5. Z-10. R-5. Q2. F800

X25. ’hole 2

Loading...

Loading...