上海维宏电子科技股份有限公司

Weihong Electronic Technology Co., Ltd.

44 Specialized, Concentrated, Focused

P_: the dwell time at the bottom of the hole, in ms, with no decimal point

F_: feed speed, even if the canned cycle is cancelled, this modal data is still effective in the

subsequent machining.

K_: number of repeats (repeated movement and drilling, effective under G91 incremental mode)

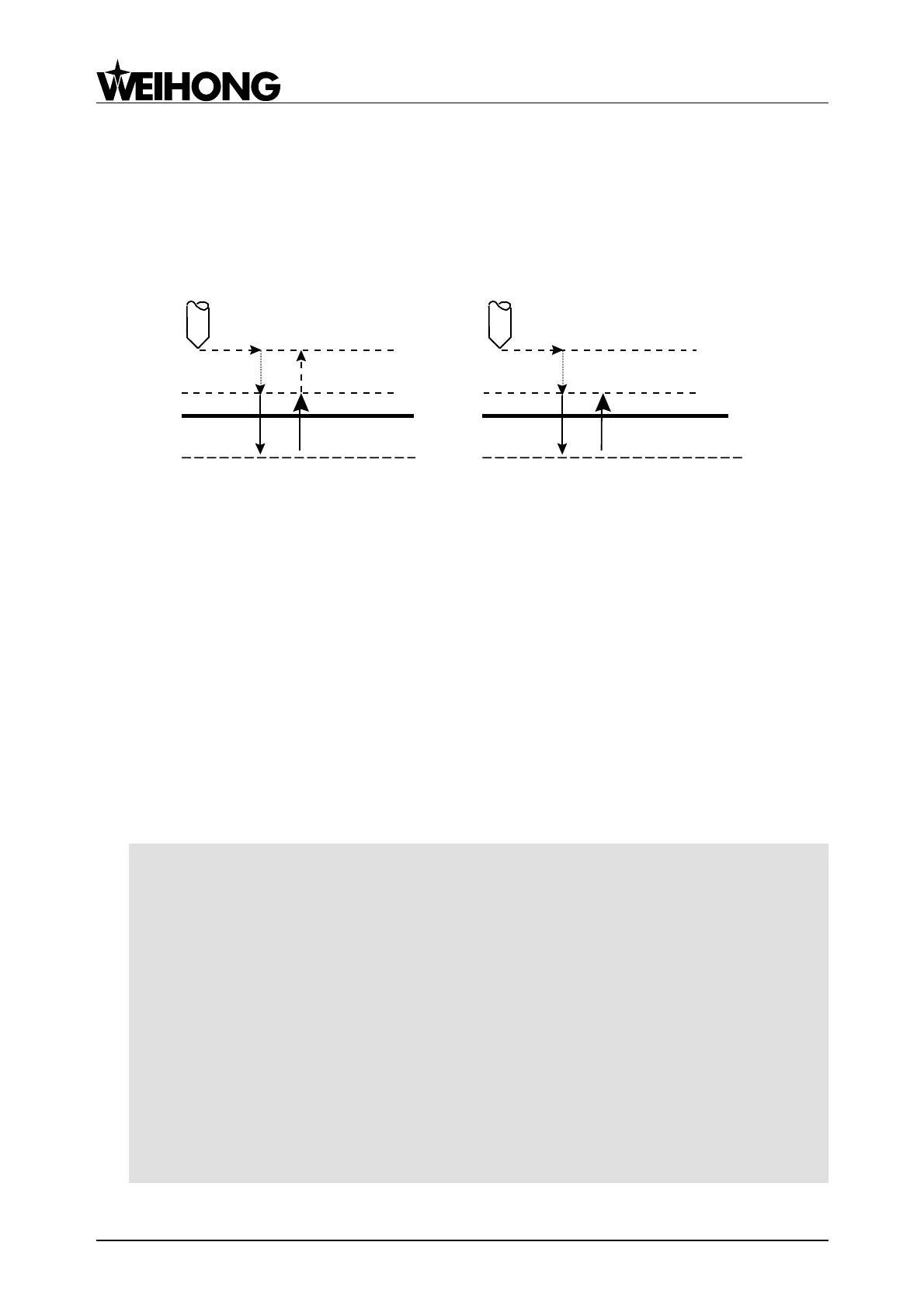

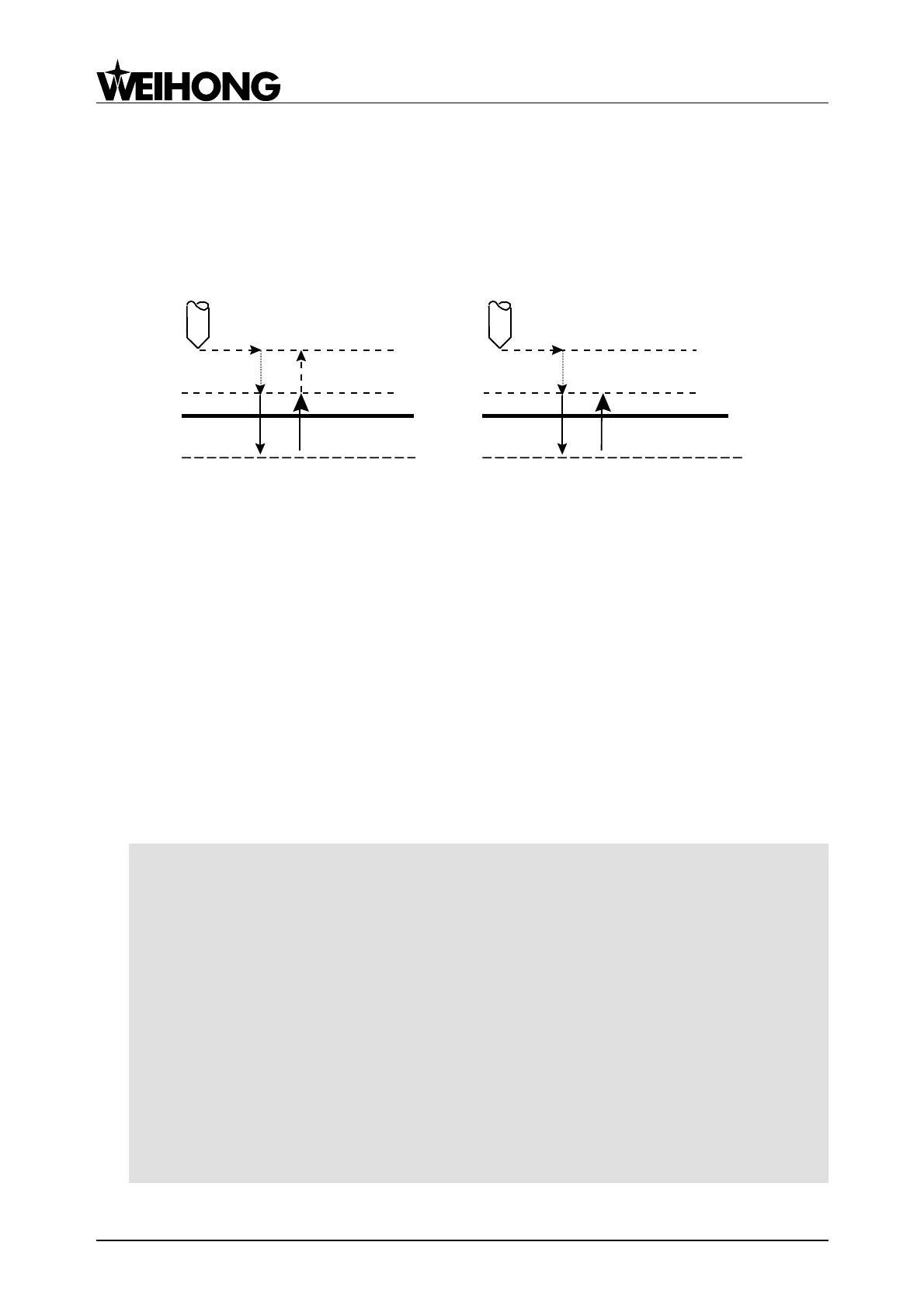

Fig. 4-31 G88 Machining Process

Process Description:

1. The cutter moves to the hole position (X, Y) in G00;

2. Moves down to the specified point R in G00;

3. Moves down to point Z at the bottom of the hole in G01;

4. Spindle stop after P;

5. Retracts to point R in G01;

6. Retracts to initial point (G98) or point R (G99) in G00;

7. Spindle CW.

Programming Example:

F1200. S600

G90

G00 X0. Y0. Z10. ’moving to the initial point

G17

M03 ’spindle CW on

G90 G99

’Specifying the coordinates of point R, point Z and hole 1, with dwell as 2(s), boring speed as 800

G88 X5. Y5. Z-10. R-5. P2000 F800

X25. ’hole 2

Y25. ’hole 3

G98 X5. ’hole 4, and setting to return to the initial point

G80

M05 ’spindle stop

M02

Loading...

Loading...