7

3.2 Basic function

Burner type

• Fully automatic oil atomising burner with fan

• Two stage operation

Digital combustion manager

Main points:

• Safety via internal fuse

• Control and monitoring of all burner functions

• Safety via two microprocessors (reciprocal monitoring)

• Data bus connection (eBUS)

• Signal lamp to show operational status (see also

Ch. 6):

Green Burner operating

Flashing green Burner operating with weak

flame signal

Orange Burner start, internal test

Flashing orange Ignition phase

Red Burner lockout

Flashing orange / red Low voltage or internal safety

fault

Flashing green / red Extraneous light

2 x flashing red / Over-voltage

orange, short pause

Flickering red Optical data transfer

(not used)

Electric servomotor

Setting of the individual operating points is carried out by

the limit and auxiliary switches on the servomotor (Ch. 5.3)

Flame sensor

Monitors the flame signal at each operating phase. If the

flame signal does not concur with the sequence of

operation, a safety shutdown is initiated.

Nozzle assembly

• The total oil throughput required is provided by a single

nozzle.

• The diffuser is set as required with the setting screw.

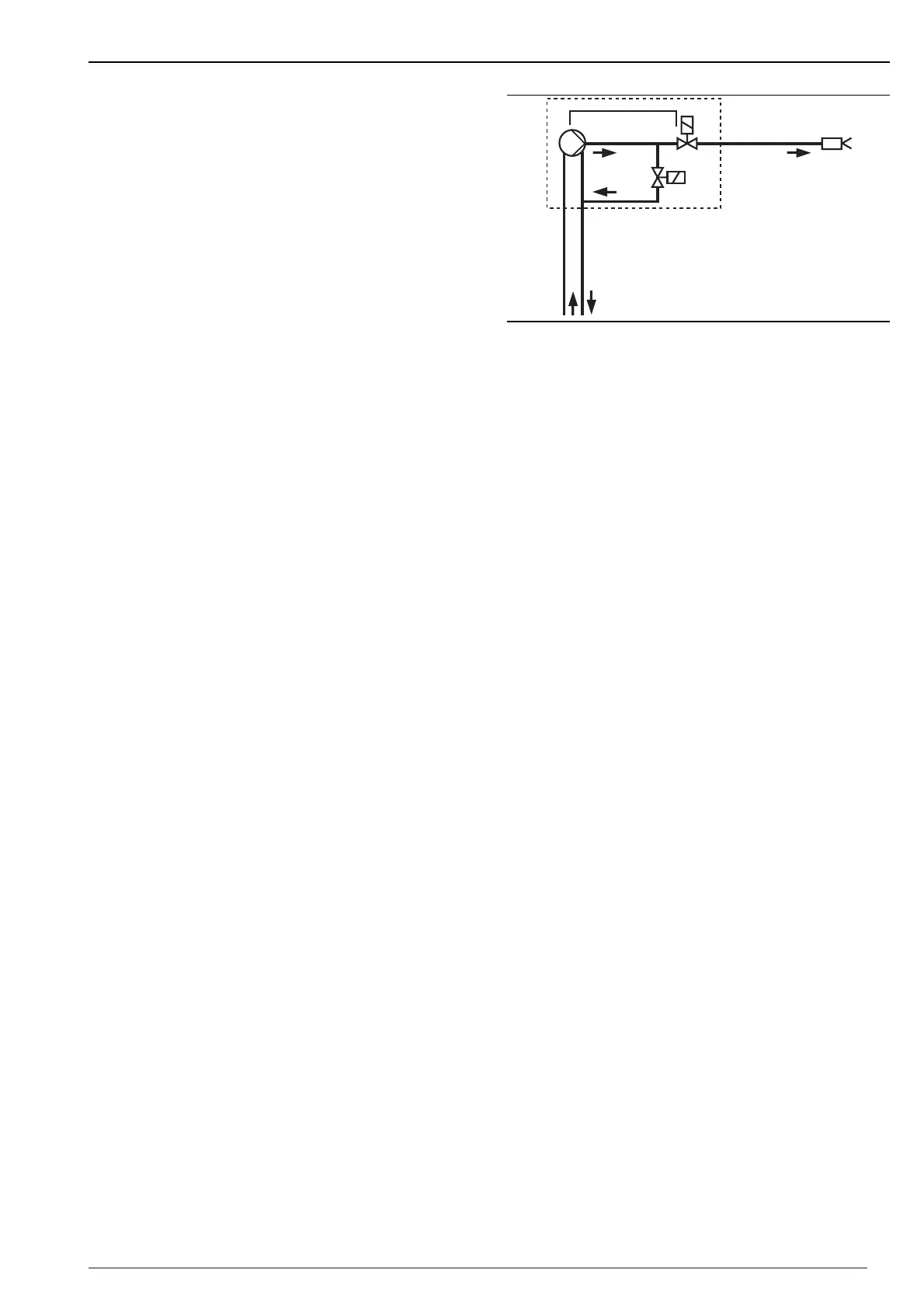

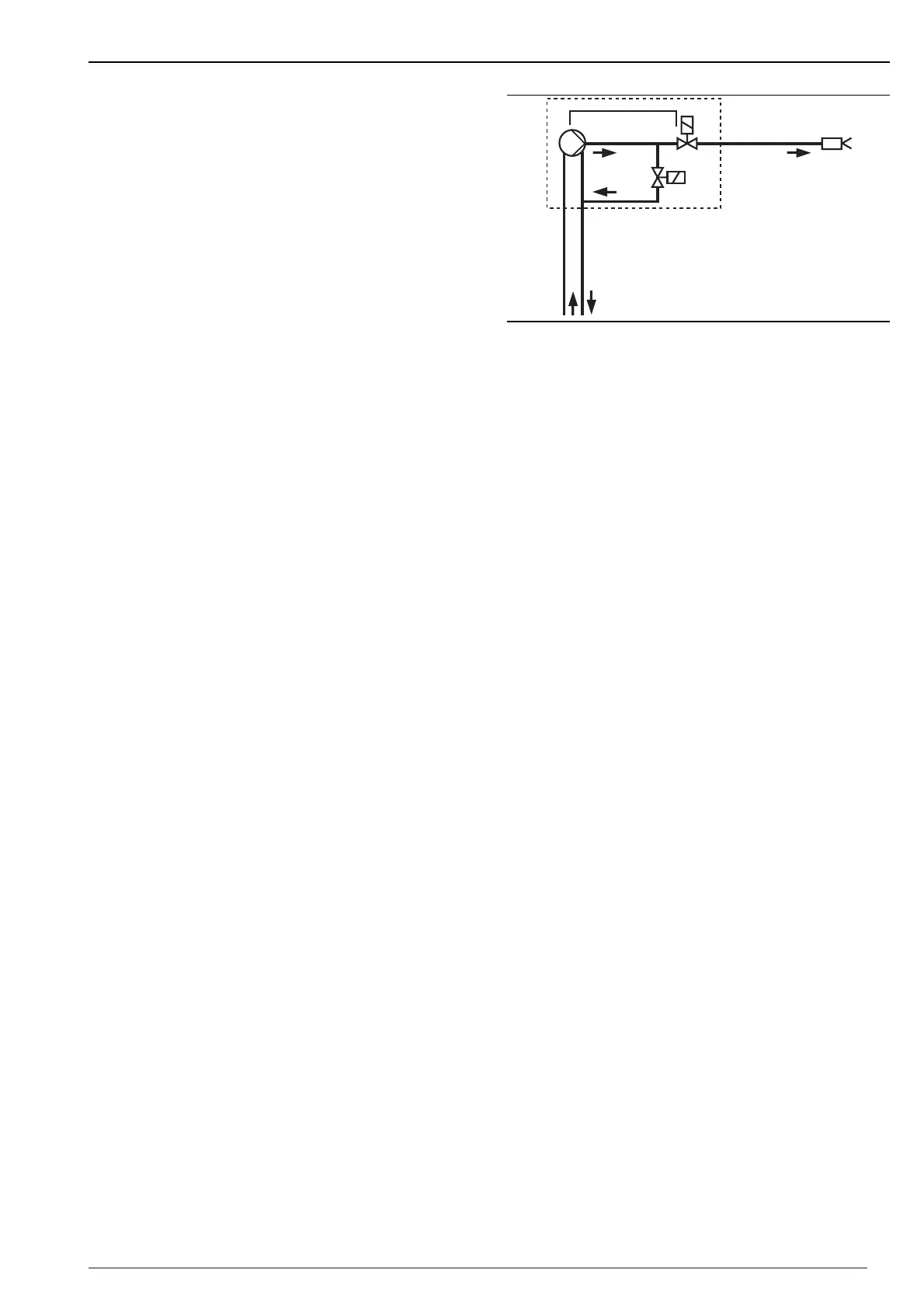

Sequence of operations

Demand for heat from the appliance’s controller:

• Fan start - pre-purge of the combustion chamber

• Ignition on

• Servomotor drives to partial load

• Solenoid valve stage 1 opens after prepurge - fuel

release

• Flame formation

• Depending on the heat required, the servomotor drives

to full load following a waiting time of approx. 5

seconds, opens the air damper and releases solenoid

valve 2.

• After 24 hrs. of continuous operation a controlled

shutdown is carried out.

Controlled shut down:

Solenoid valve closes

• Post-purge of the combustion chamber

• Burner switches off - Standby

Loading...

Loading...