18

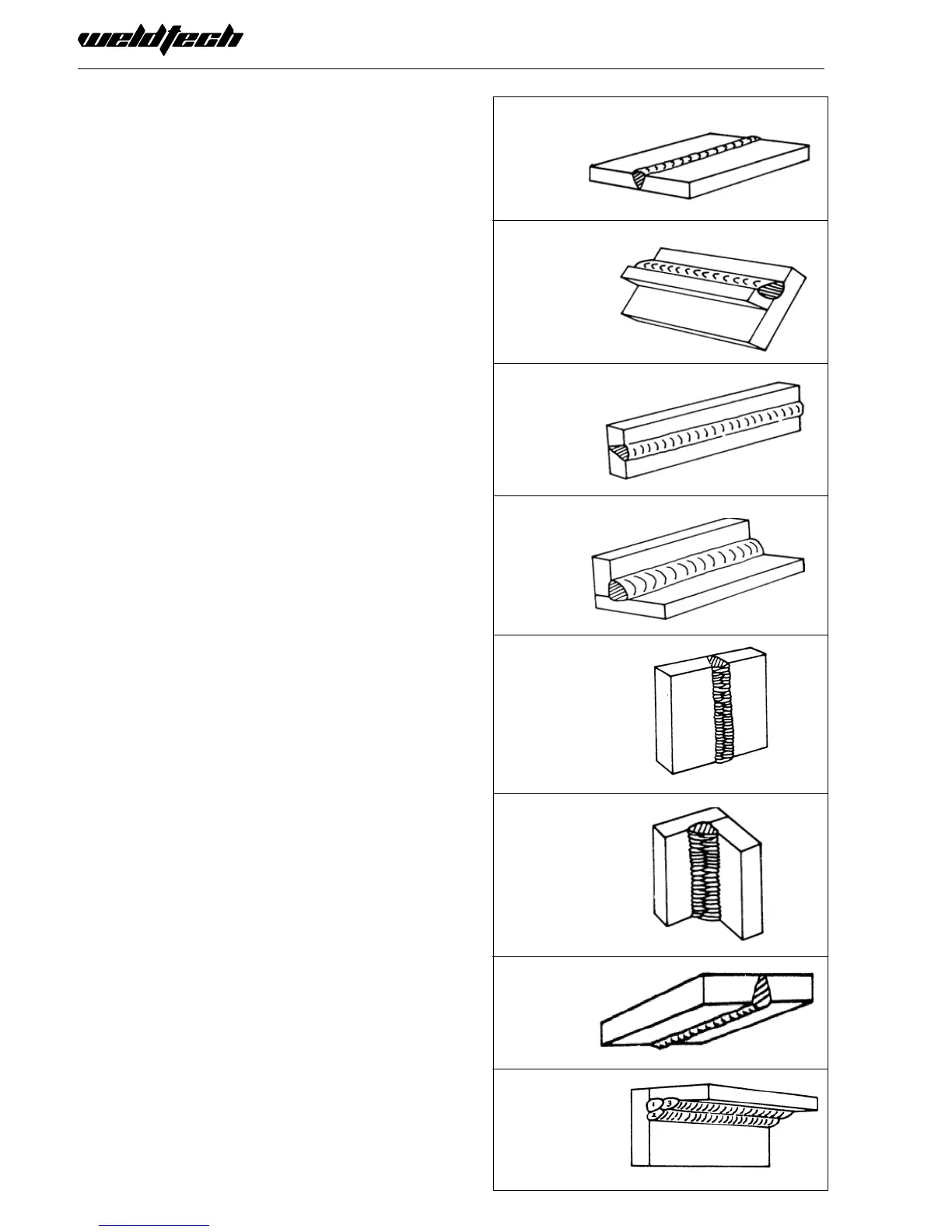

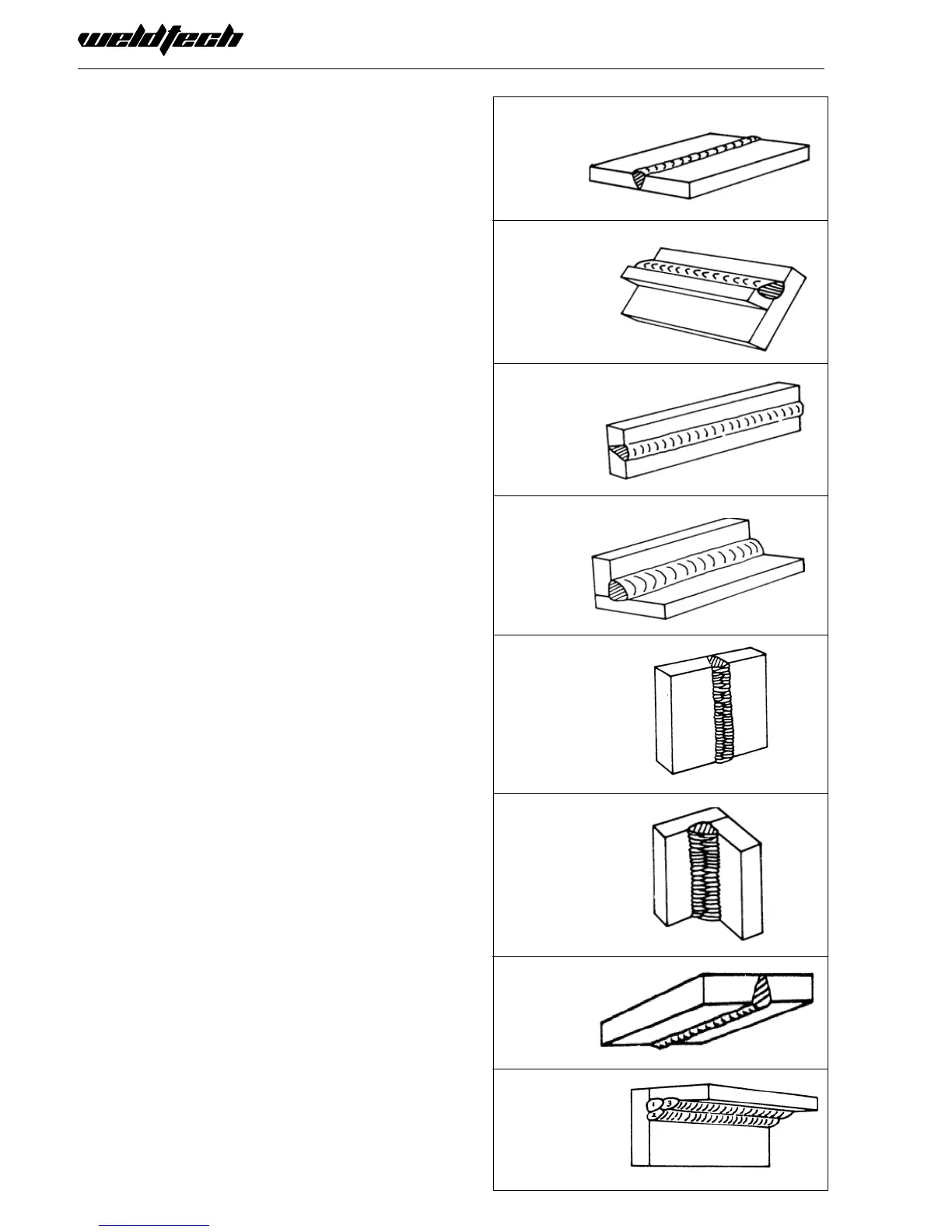

Flat Position,

Down Hand Butt Weld

(Fig 1-11)

Flat Position,

Gravity Fillet Weld

(Fig 1-12)

Horizontal Position,

Butt Weld

(Fig 1-13)

Horizontal-Vertical

(HV) Position

(Fig 1-14)

Vertical Position,

Butt Weld

(Fig 1-15)

Vertical Position,

Fillet Weld

(Fig 1-16)

Overhead Position,

Butt Weld

(Fig 1-17)

Overhead Position,

Fillet Weld

(Fig 1-18)

MMA (Stick) Basic

Welding Guide

Size of Electrodes

The electrode size is determined by the thickness of

metals being joined and can also be governed by

thetypeofweldingmachineavailable.Smallweld-

ingmachineswillonlyprovidecurrent(amperage)to

run smaller sized electrodes.

Forthinsections,itisnecessarytousesmallerelec-

trodes otherwise the arc may burn holes through

the job. A little practice will soon establish the most

suitableelectrode for a given application.

Storage of Electrodes

Always store electrodes in a dry place and in their

original containers.

Electrode Polarity

Electrodes are generally connected to the electrode

holder with the electrode holder connected positive

polarity.

The work lead is connected to the negative polarity

and is connected to the work piece. If in doubt con-

sult the electrode data sheet.

Eects of MMA(Stick) Welding on

Various Materials

High Tensile and Alloy Steels

The two most prominent eects of welding these

steels are the formation of a hardened zone in the

weld area, and, if suitable precautions are not taken,

the occurrence in this zone of under-bead cracks.

Hardenedzoneandunderbeadcracksintheweld

area may be reduced by using the correct elec-

trodes, preheating, using higher current settings,

using larger electrodes sizes, short runs for larger

electrode deposits or tempering in a furnace.

Manganese Steels

The eect on manganese steel of slow cooling from

hightemperaturescausesembrittlement.Forthis

reason it is absolutely essential to keep manganese

steelcool during welding by quenching after each

weld or skip welding to distribute the heat.

Cast Iron

Mosttypesofcastiron,exceptwhiteiron,areweld-

able. White iron, because of its extreme brittleness,

Loading...

Loading...