20

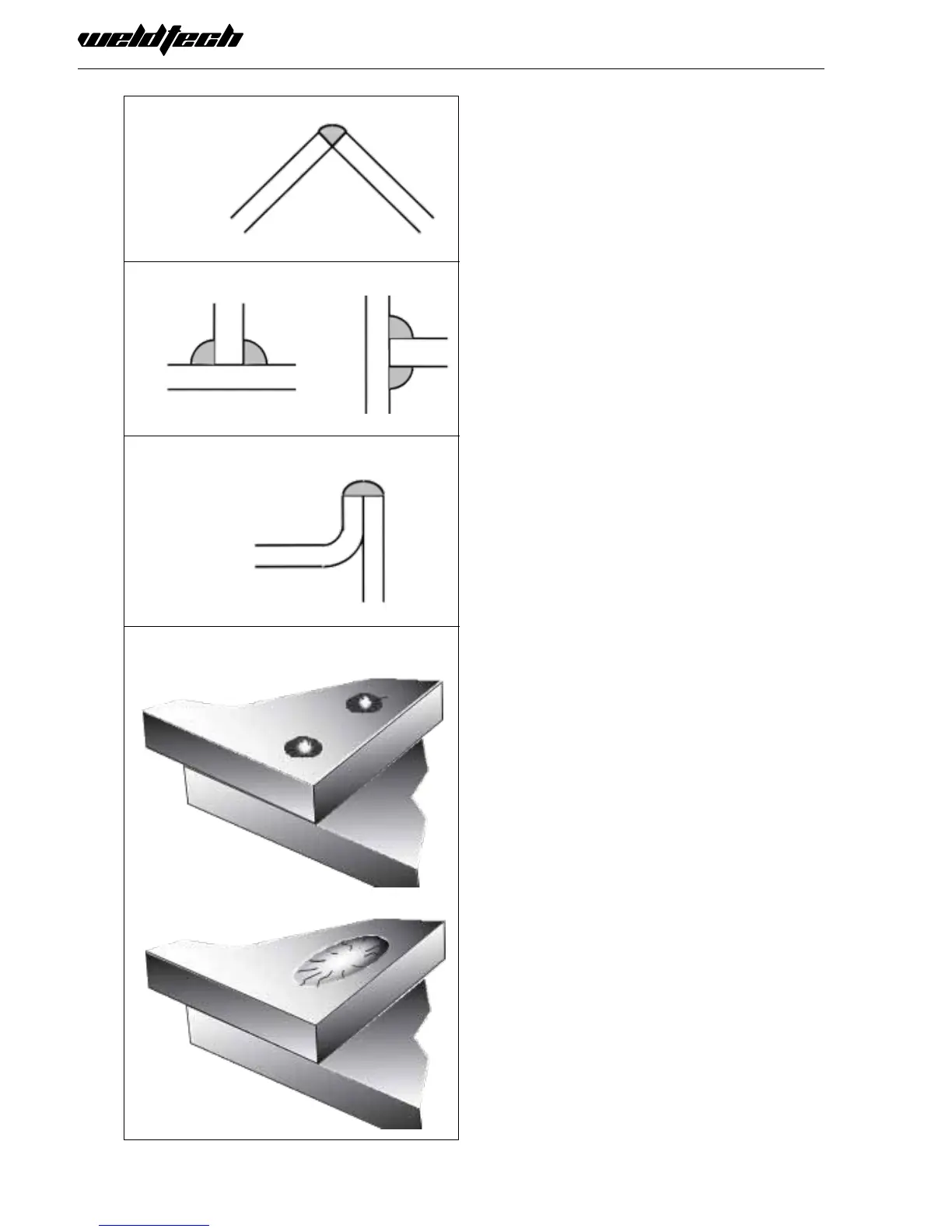

Corner Weld

(Fig 1-19g)

Tee Joints

(Fig 1-19h)

Edge Joint

(Fig 1-19i)

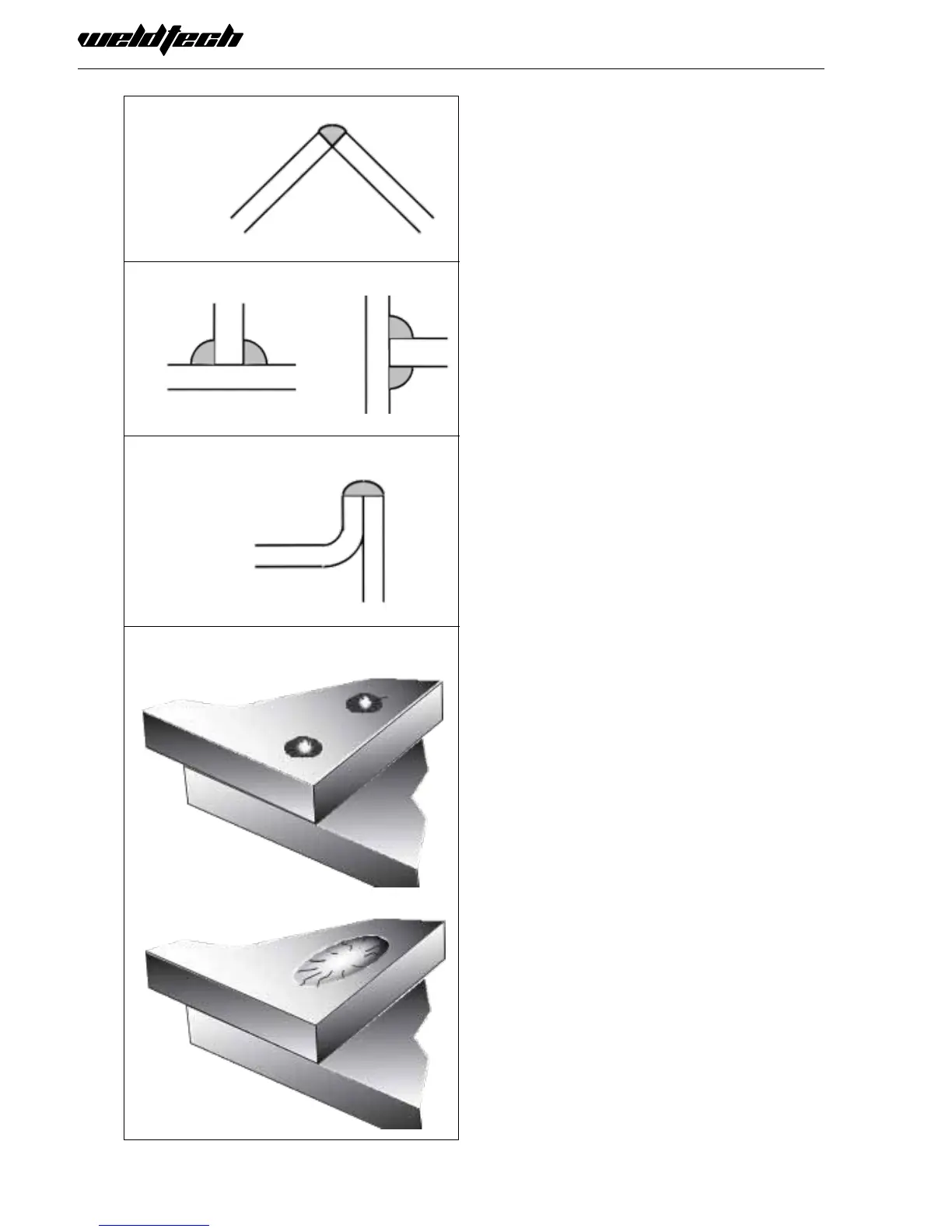

Plug Welds

(Fig 1-19j)

Arc Welding Techniques

- A Word for Beginners

Forthosewhohavenotyetdoneanywelding,the

simplest way to commence is to run beads on a piece

ofscrapplate.Usemildsteelplateabout6.0mmthick

and a 3.2mm electrode.

Clean any paint, loose scale or grease o the plate and

set it rmly on the work bench so that welding can

becarriedoutinthedownhandposition.Makesure

thattheWorkLead/Clampismakinggoodelectrical

contact with the work, either directly or through the

work table. For light gauge material, always clamp

the work lead directly to the job, otherwise a poor

circuit will probably result.

The Welder

Place yourself in a comfortable position before be-

ginning to weld. Get a seat of suitable height and

do as much work as possible sitting down. Don’t

hold your body tense. A taut attitude of mind and

a tensed body will soon make you feeltired.Relax

and you will nd that the job becomes much easier.

You can add much to your peace of mind by wearing

a leather apron and gauntlets. You won’t be worry-

ing then about being burnt or sparks setting alight

to your clothes.

Place the work so that the direction of welding is

across, rather than to or from, your body. The elec-

trode holder lead should be clear of any obstruction

so that you can move your arm freely along as the

electrode burns down. If the lead is slung over your

shoulder, it allows greater freedom of movement

andtakesalotofweightoyourhand.Besurethe

insulation on your cable and electrode holder is not

faulty; otherwise you are risking an electric shock.

Striking the Arc

Practice this on a piece of scrap plate before going

on to more exacting work. You may at rst experi-

encedicultyduetothetipoftheelectrode“stick-

ing”totheworkpiece.Thisiscausedbymakingtoo

heavy a contact with the work and failing to with-

draw the electrode quickly enough. A low amper-

age will accentuate it. This freezing-on of the tip may

be overcome by scratching the electrode along the

plate surface in the same way as a match is struck. As

soon as the arc is established, maintain a 1.6mm to

3.2mm gap between the burning electrode end and

Loading...

Loading...