16

MIG Welding

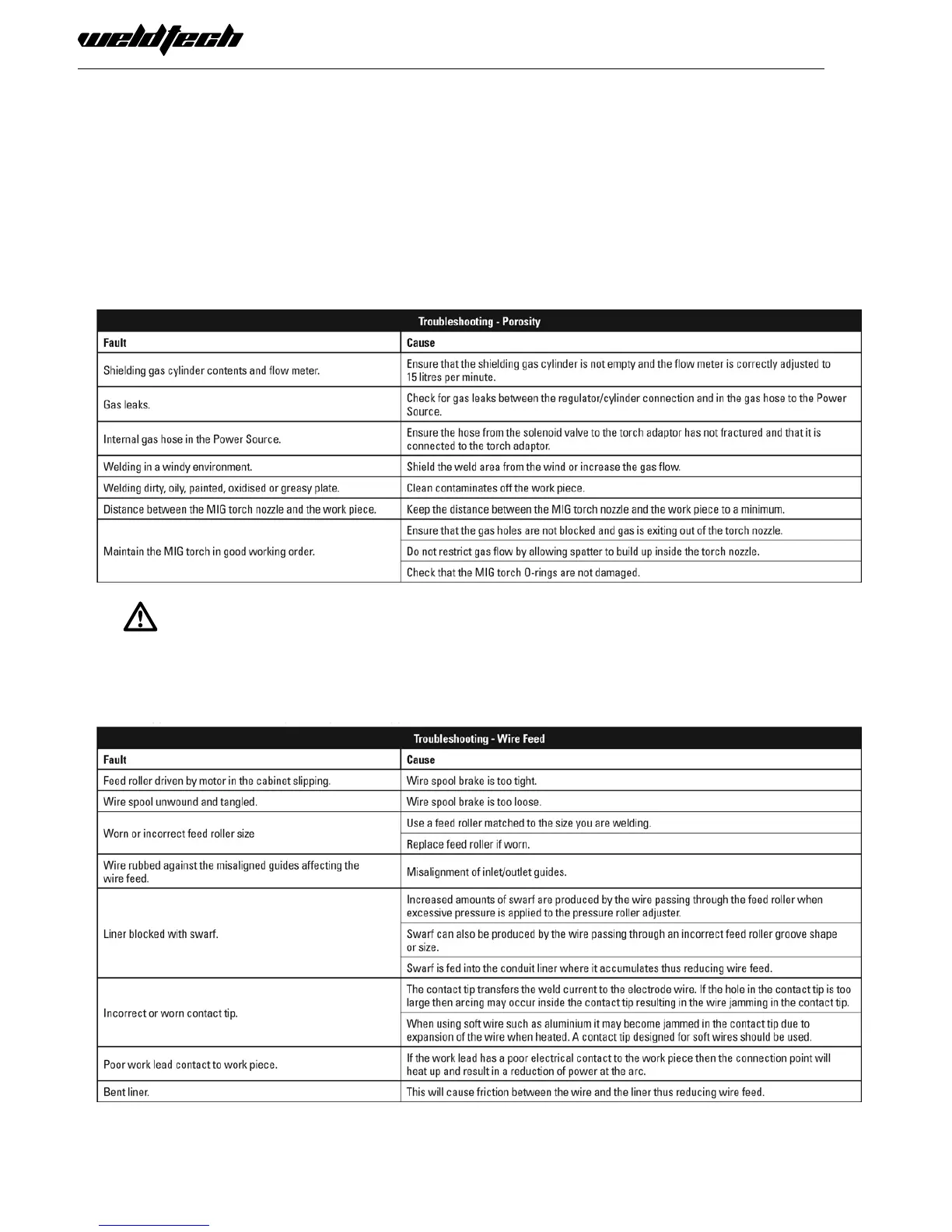

Troubleshooting

ThegeneralapproachtoxGasMetalArcWelding

(GMAW)problemsistostartatthewirespoolthen

workthroughtotheMIGtorch.Therearetwomain

areas where problems occur with GMAW, Porosity

and Inconsistent wire feed.

When there is a gas problem the result is usually po-

rosity within the weld metal. Porosity always stems

from some contaminant within the molten weld

pool which is in the process of escaping during so-

lidication of the molten metal.

Contaminants range from no gas around the weld-

ing arc to dirt on the workpiece surface. Porosity can

be reduced by checking the following points.

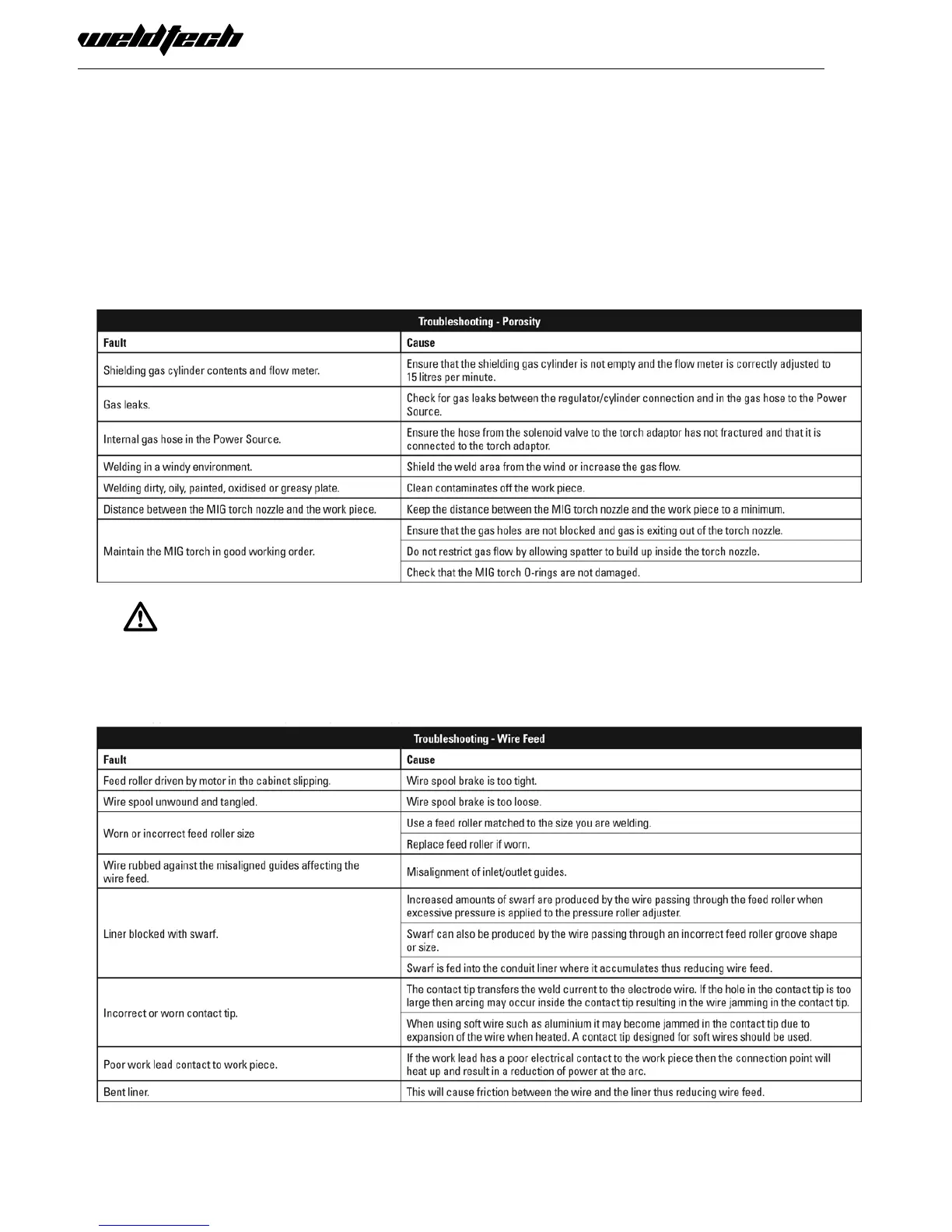

WARNING!

Disengage the feed roll when testing for gas ow by ear.

Wire feeding problems can be reduced by checking the following points.

Loading...

Loading...