25

WT200MP Welding Machine

www.weldtech.net.nz

TIG Basic Welding

Guide

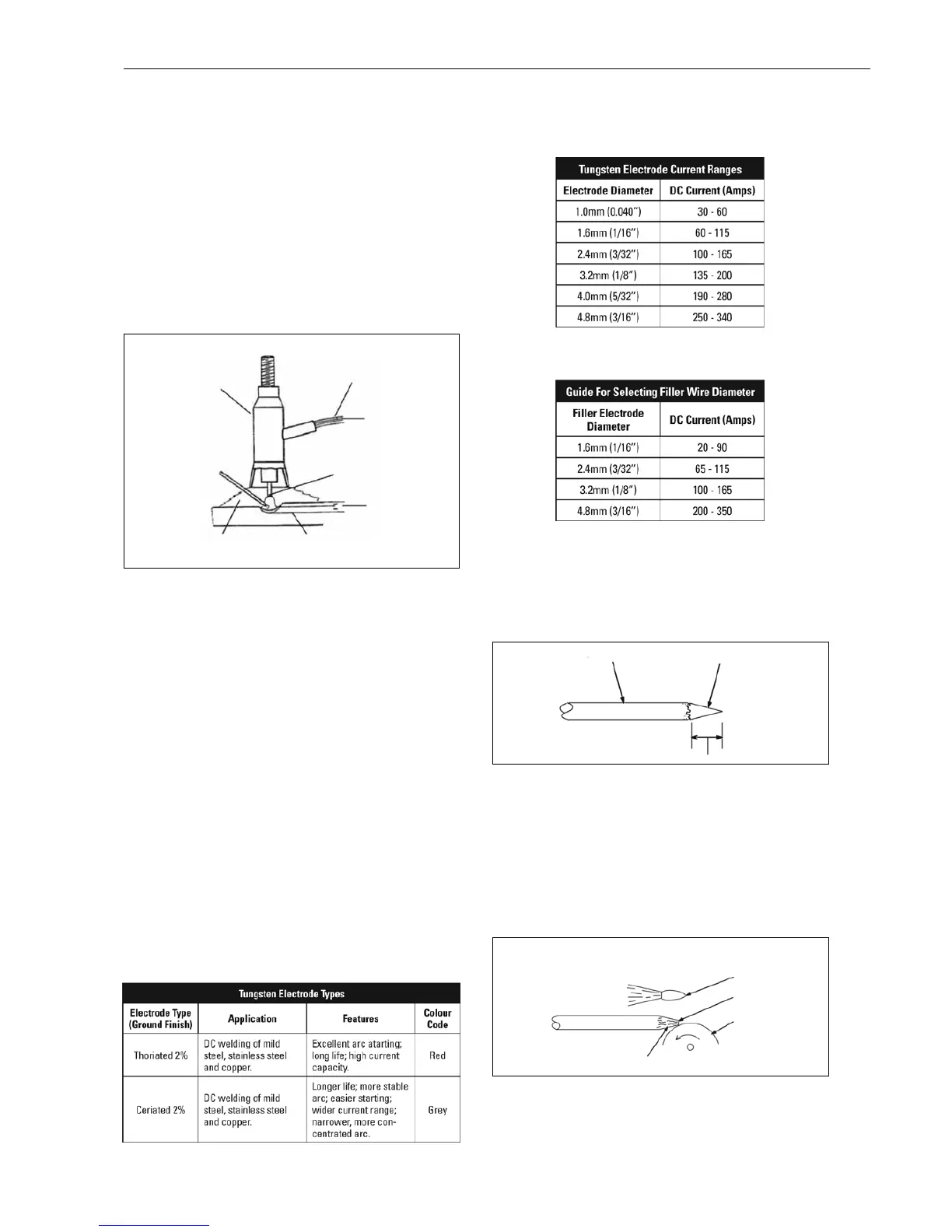

TIGWeldingisafusionprocedurethatusesanelec-

tricARCcreatedbetweenaninfusibletungstenelec-

trodeandbasematerialtobewelded.ForTIGweld-

inganinertgasmustbeused(Argon)whichprotects

the welding bead. If lling material is used, it is made

up of rods suitable to the material to be welded

(steel,stainlesssteel,copperetc).

Electric Current

InertGas

Tungsten Electrode

Deposit

MeltedArea

Penetration

BaseMaterial

ProtectiveGas

Rod

Torch

TIG Welding

(Fig 15)

InTIGmode,weldingispossibleinallpositions:at,

angle,on theedge, vertical and overhead.Further-

more, with respect to other types of welding, the

welding joint has greater mechanical resistance,

greater corrosion resistance and limited heating in

the welded area which limits distortion. Welding can

be done even without weld material, guaranteeing a

smooth, shiny weld with no impurities or slag.

Tig Electrode Selection

and Preparation

Electrode Polarity

ConnecttheTIGtorchtothenegative(-)torchtermi-

nalandtheworkleadtothepositive(+)worktermi-

nal for direct current straight polarity. Direct current

straight polarity is the most widely used polarity for

DCTIG welding. It allows limited wearof the elec-

Tungsten Electrode

Tapered End

2.5xElectrodeDiameter

(Fig 16-1)

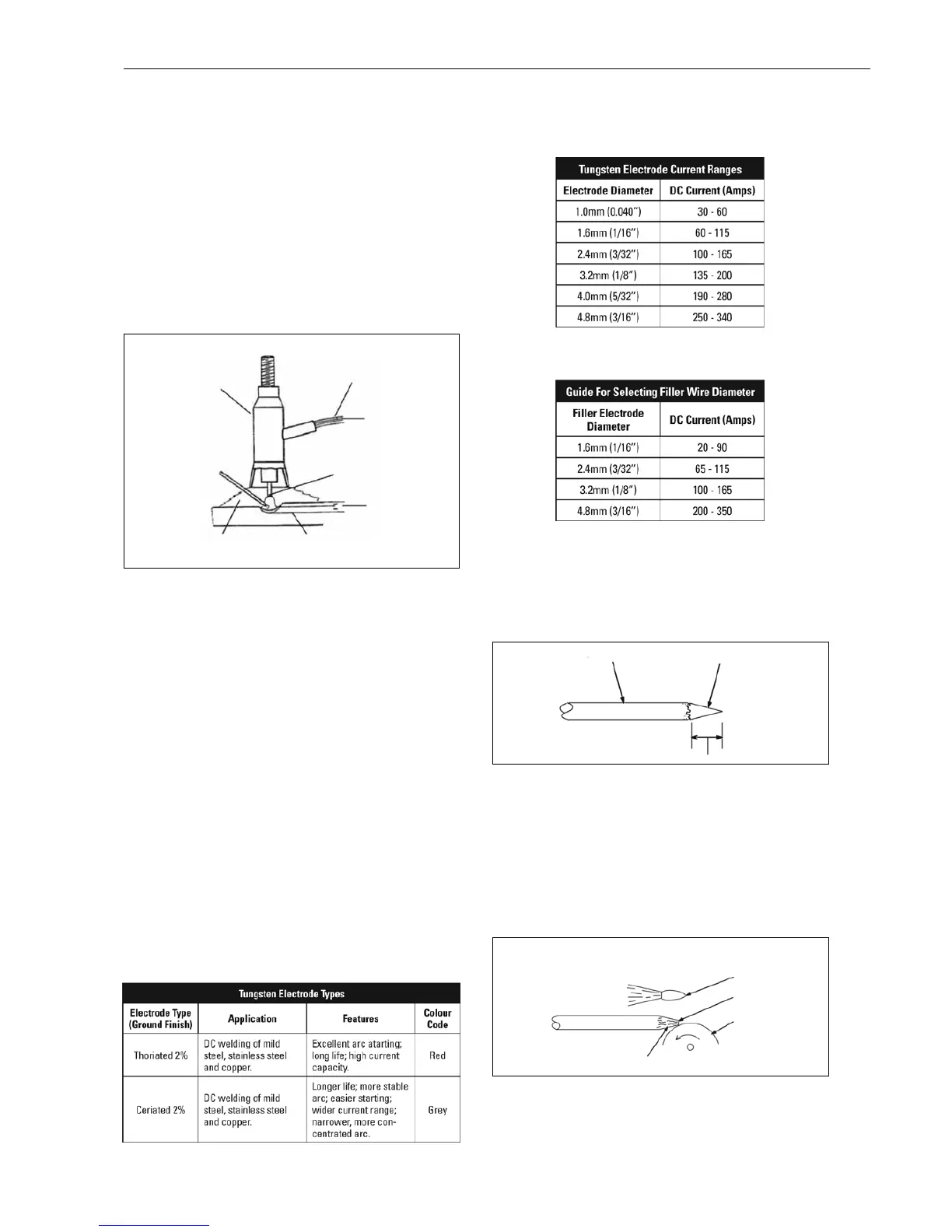

Preparing Tungsten for DC Electrode Negative

(DCEN) Welding

2.5 x Electrode Diameter

Grind end of tungsten on ne grit, hard abrasive

wheel before welding. Do not use wheel for other

jobs or tungsten can become contaminated causing

lower weld quality.

(Fig 16-2)

StableARC

Grinding

Wheel

Ideal Tungsten Preparation - Stable ARC

Diameter of the at determines amperage capacity.

Flat

StraightGround

trode since 70% of the heat is concentrated at the

work piece.

Loading...

Loading...