19

WT200MP Welding Machine

www.weldtech.net.nz

MILD STEEL :

E6011 - This electrode is used for all-position welding or

for welding on rusty, dirty, less-than- new metal. It has

a deep, penetrating arc and is often the rst choice for

repair or maintenance work.

E6013 - This all-position electrode is used for welding

clean, new sheet metal. Its soft arc has minimal spatter,

moderate penetration and an easy-to-clean slag.

E7014 - All positional, ease to use electrode for use on

thicker steel than E6013. Especially suitable for sheet metal

lap joints, llet welds and general purpose plate welding.

E7018 - A low-hydrogen, all-position electrode used when

quality is an issue or for hard-to-weld metals. It has the ca-

pability of producing more uniform weld metal, which has

better impact properties at low temperatures.

CAST IRON:

ENI-CL -Suitableforjoiningallcastironsexceptwhite

cast iron.

STAINLESS STEEL:

E318L-16 -Highcorrosionresistances.Idealfordairy

work etc.

Electrodes for joining dierent metals:

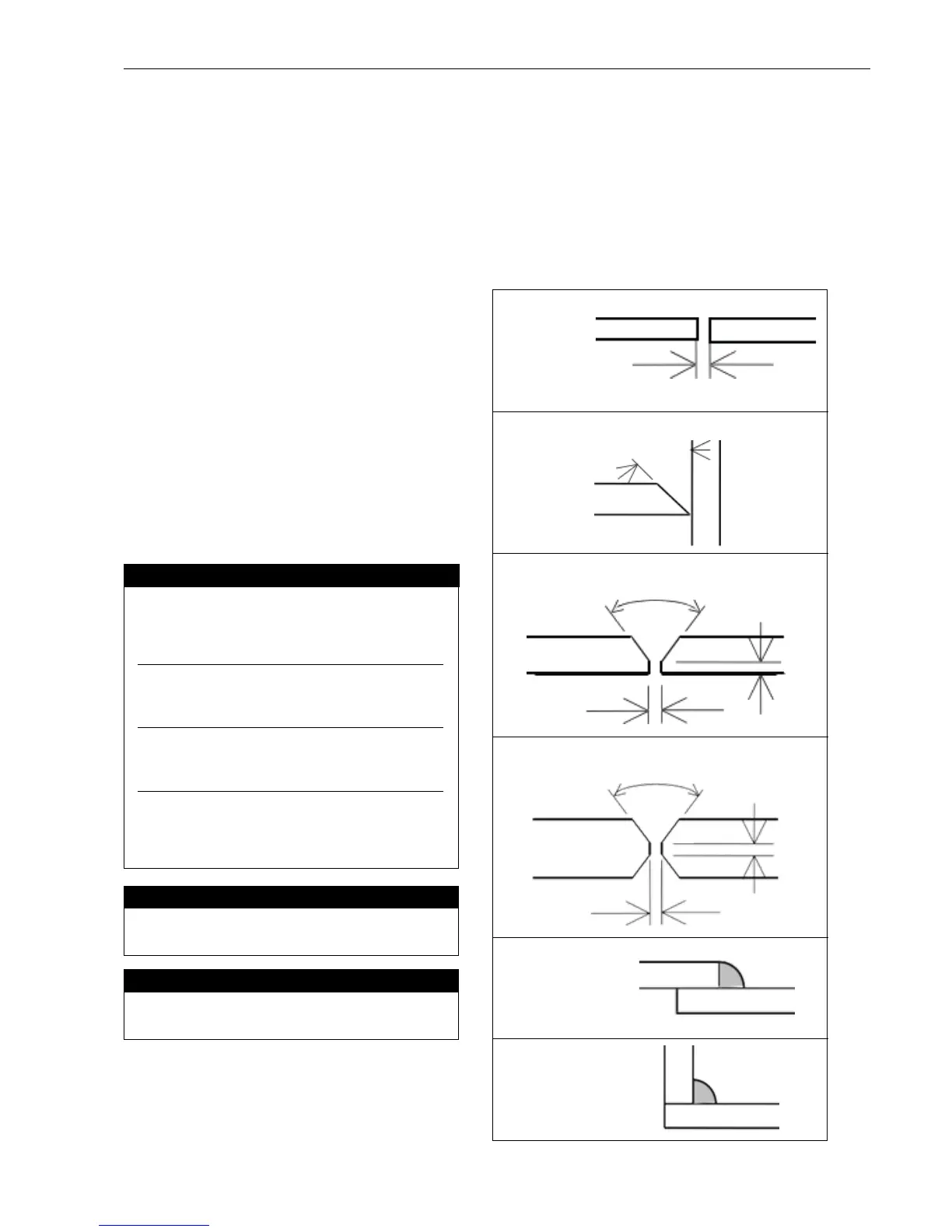

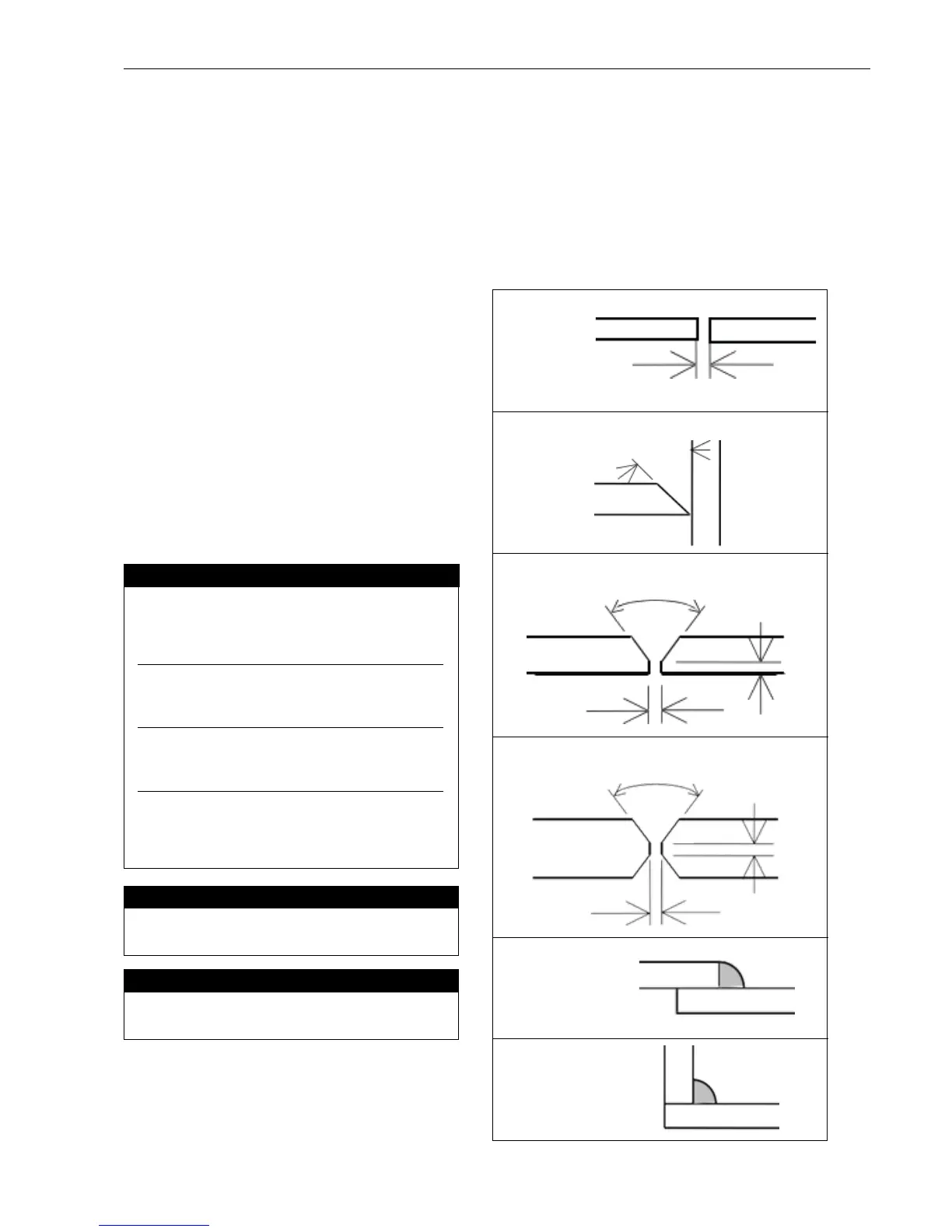

Joint Preparations

In many cases, it will be possible to weld steel sec-

tions without any special preparation. For heavier

Open Square Butt Joint

(Fig 1-19a)

Gapvariesfrom1.6mm(1/16”)

to4.8mm(3/16”)dependingonplatethickness

Single Vee Butt Joint

(Fig 1-19b)

Notlessthan45°

Single Vee Butt Joint

(Fig 1-19c)

Notlessthan70°

1.6mm(1/16”)max.

1.6mm(1/16”)

Double Vee Butt Joint

(Fig 1-19d)

Notlessthan70°

1.6mm(1/16”)max.

1.6mm(1/16”)

Lap Joint (Fig 1-19e)

Fillet Joint (Fig 1-19f)

generally cracks when attempts are made to weld it.

Trouble may also be experienced when welding

white-heart malleable, due to the porosity caused by

gas held in this type of iron.

Copper and Alloys

The most important factor is the high rate of heat

conductivity of copper, making pre-heating of heavy

sections necessary to give proper fusion of weld and

base metal.

Types of Electrodes

Arc Welding electrodes are classied into a number

of groups depending on their applications. There are

a great number of electrodes used for specialised in-

dustrial purposes which are not of particular interest

for everyday general work. These include some low

hydrogen types for high tensile steel, cellulose types

for welding large diameter pipes, etc. The range of

electrodes dealt with in this publication will cover

the vast majority of applications likely to be encoun-

tered; are all easy to use.

sections and for repair work on castings, etc., it will

be necessary to cut or grind an angle between the

pieces being joined to ensure proper penetration of

the weld metal and to produce sound joints.

In general, surfaces being welded should be clean

andfreeofrust,scale,dirt,grease,etc.Slagshouldbe

removed from oxy-cut surfaces. Typical joint designs

areshowninFigure1-19.

Loading...

Loading...