12

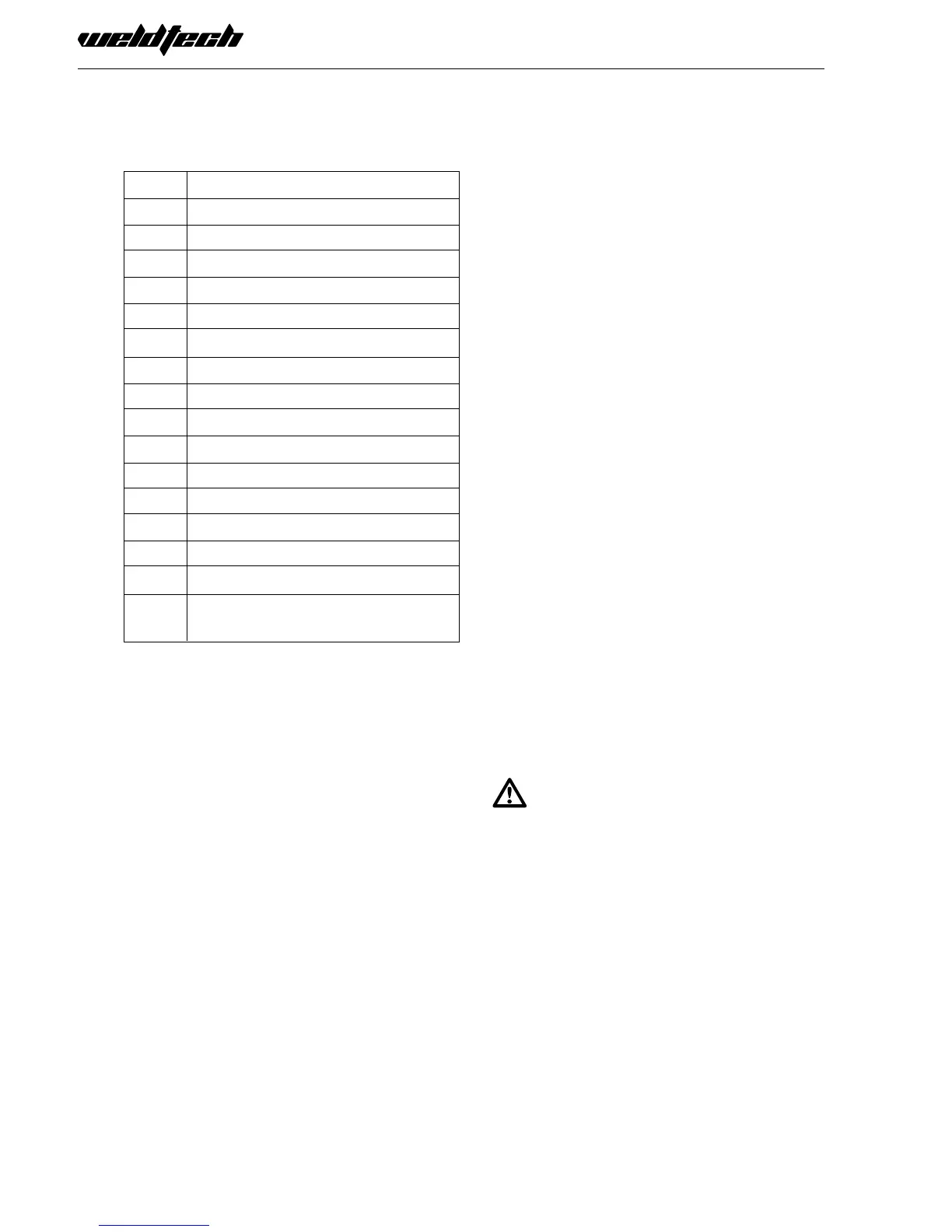

Spare Parts for WT200MP

Part #: Description:

17257 CoolingFan

17252 WeldingModeSwitch

17261 WireFeederAssembly

17262 Potentiometer

17263 MainPCBAssembly

17264 GasSolenoid

17265 DigitalDisplayMeter

17266 ControlKnob-Blue

17267 Potentiometer 33K

17268 MIGTorchSocket

17269 SpoolHolderAssembly

17270 WireDriveRoller0.6/0.8mmVGroove

17271 WireDriveRoller0.9/1.0mmVGroove

17272 WireDriveRoller0.8/0.9mmKnurledGroove

13323 WeldtechSpoolGunAssembly

MB15KIT MIGConsumablesStarterKit-MB15.17512

15kg-5kgspoolspacer

Care &

Maintenance

Keep your Welding Machine

in Top Condition

TheWT200MPdoesnotrequireanyspecialmainte-

nance, however the user should take care of the ma-

chine as follows:

• Regularlycleantheventilationslots.

• Keepthecasingclean.

• Checkallcablesbeforeuse.

• Checkelectrodeholders,worklead/clampsand

welding torches before use.

• Replacewornelectrodeholdersandearth

clamps, which do not provide a good

connection.

• Replaceworntorchconsumablepartsinatimely

manner.

• Replacewornwiredrivecomponentsinatimely

manner

• Use a soft cloth or brush to clean electrical

components. Do not use liquid cleaning products,

water or especially solvents.

• Donotusecompressedairtocleanelectrical

components as this can force dirt and dust

further into components, causing electrical short

circuits.

• Checkfordamagedparts.Donotusethewelder

with damaged parts.

If damaged, before further use, the welder must be

carefully checked by a qualied person to determine

that it will operate properly. Check for breakage of

parts, mountings and other conditions that may

aect its operation.

Have your welder repaired by an expert. An

authorised service centre should properly repair a

damaged part.

This appliance is manufactured in accordance with

relevant safety standards. Only experts must carry

out repairing of electrical appliances, otherwise

considerabledangerfortheusermayresult.Useonly

genuine replacement parts. Do not use modied or

non-genuine parts.

Storing the Welder

When not in use the welder should be stored in the

dry and frost-free environment.

WARNING! Before performing cleaning/main-

tenance, replacing cables / connections , make

sure the welding machine is switched o and

disconnected from the power supply.

MIG Basic

Welding Guide

Mig Basic Welding Techniques

Two dierent welding processes are covered in this

section(GMAWandFCAW),withtheintentionofpro-

vidingtheverybasicconceptsinMIGwelding,where

aweldinggunishandheld,andtheelectrode(weld-

ing wire) is fed into a weld puddle, and the arc is

shieldedbyagas(GMAW)oruxcoredwire(FCAW).

Loading...

Loading...