13

WT200MP Welding Machine

www.weldtech.net.nz

Gas Metal ARC Welding (GMAW).

Thisprocess,alsoknownasMIGwelding,CO2weld-

ing,MicroWireWelding,shortarcwelding,diptrans-

fer welding, wire welding etc., is an electric arc weld-

ing process which fuses together the parts to be

welded by heating them with an arc between a solid

continuous, consumable electrode and the work.

Shielding is obtained from an externally supplied

welding grade shielding gas. The process is normally

applied semi automatically; however the process

may be operated automatically and can be machine

operated. The process can be used to weld thin and

fairly thick steels, and some non-ferrous metals in all

positions.

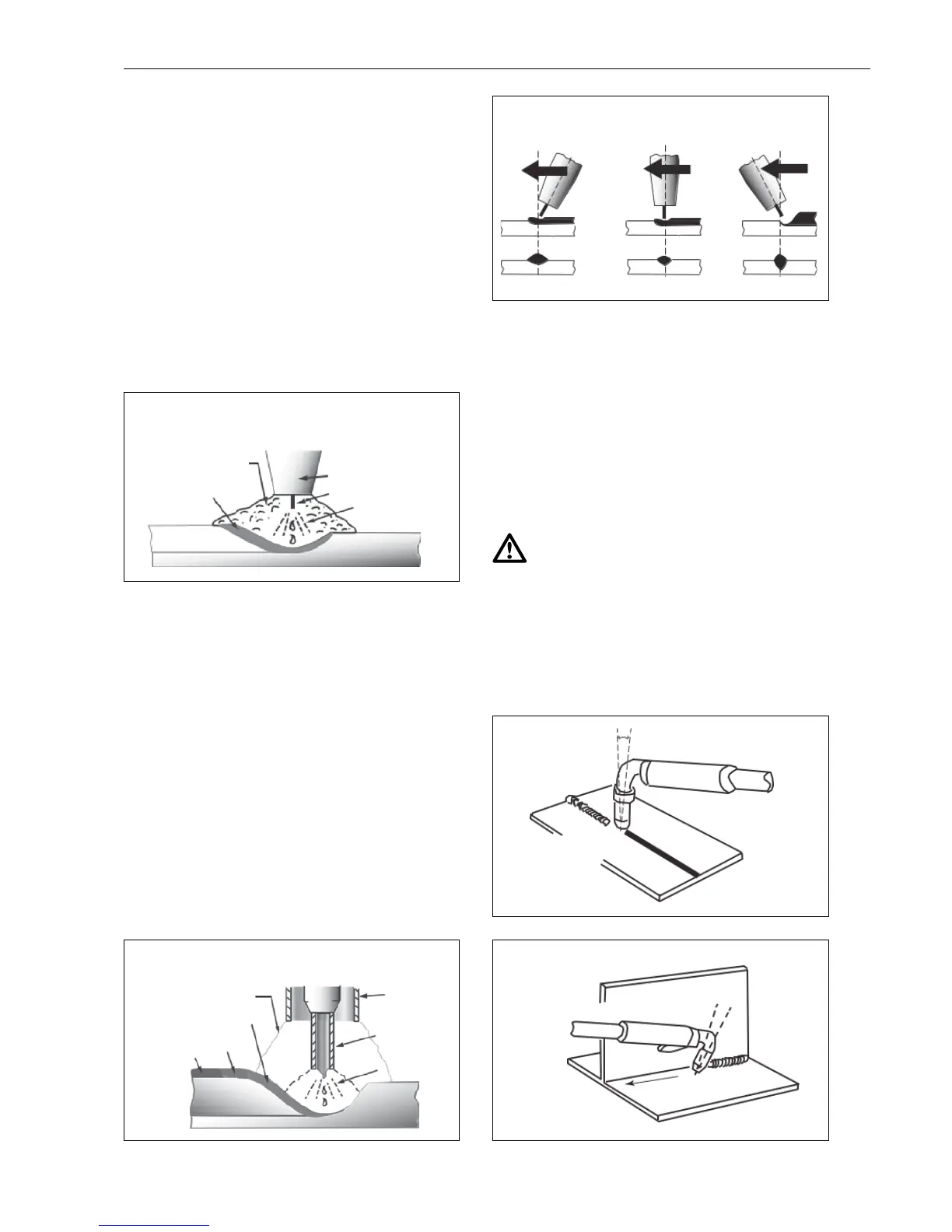

GMAW Process

(Fig 1-1)

ShieldingGas

MoltenWeldMetal

Nozzle

Electrode Arc

BaseMetal

SolidiedWeldMetal

Flux Cored Arc Welding (FCAW)

This is an electric arc welding process which fuses to-

gether the parts to be welded by heating them with

an arc between a continuous ux lled electrode

wireandthework.Shieldingisobtainedthroughde-

composition of the ux within the tubular wire. Ad-

ditional shielding may or may not be obtained from

an externally supplied gas or gas mixture. The pro-

cess is normally applied semi automatically; however

the process may be applied automatically or by ma-

chine.

It is commonly used to weld large diameter elec-

trodes in the at and horizontal position and small

electrode diameters in all positions. The process is

used to a lesser degree for welding stainless steel

and for overlay work.

FCAW Process

(Fig 1-2)

Nozzle

(Optional)

FluxCored

Electrode

Arc

Base

Metal

Solidied

WeldMetal

Slag

Molten

Slag

MoltenMetal

ShieldingGas

(Optional)

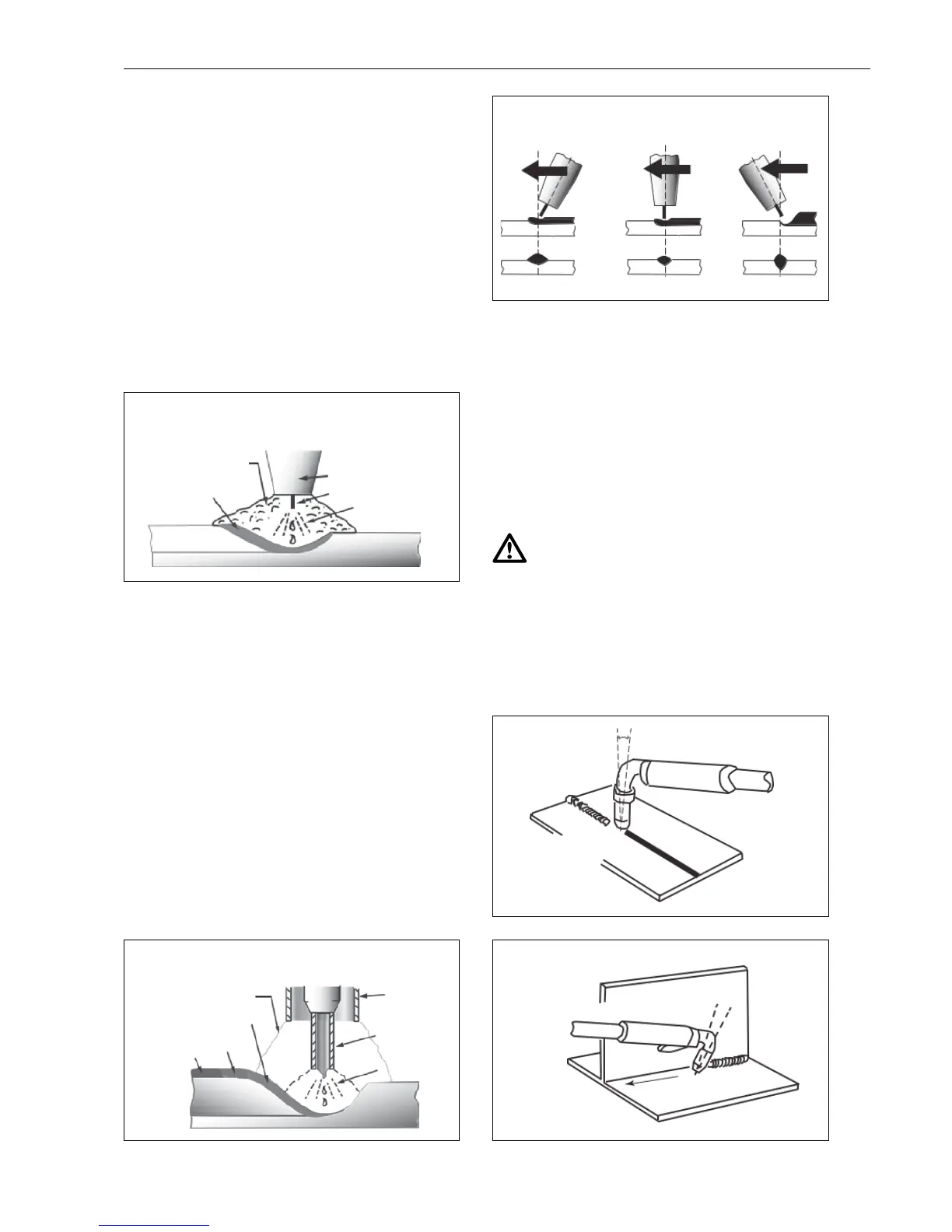

Push

Vertical Drag Pull

Position of MIG Torch

(Fig 1-3)

TheangleofMIGtorchtotheweldhasaneecton

the width of the weld.

The welding gun should be held at an angle to the

weldjoint.(SeeSecondaryAdjustmentVariablesbe-

low).

Holdthegunsothattheweldingseamisviewedat

all times. Always wear the welding helmet with prop-

er lter lenses and use the proper safety equipment.

CAUTION!

Do not pull the welding gun back when the arc is

established. This will create excessive wire exten-

sion (stick-out) and make a very poor weld.

The electrode wire is not energized until the gun

trigger switch is depressed. The wire may therefore

be placed on the seam or joint prior to lowering the

helmet.

(Fig 1-4)

5

o

to15

o

LongitudinalAngle

Direction of Travel

90

o

Transverse

Angle

(Fig 1-5)

5

o

to15

o

LongitudinalAngle

30

o

to 60

o

Transverse

Angle

Direction

of Travel

Loading...

Loading...