OPERATION

GENERAL DRILLING GUIDELINES - DRILLING A HOLE

1. Mark where you want to drill in workpiece by using a center punch or a sharp nail or turn ON the laser to

mark your drilling point.

2. Before turning the drill press ON, turn the feed handles to bring the drill bit down. Line the drill bit tip up

with the mark. Clamp the workpiece in place.

3. Turn ON the drill press and pull down on the feed handles with the appropriate force needed to allow the

drill bit to drill the material.

NOTE: Feeding too slowly might cause the drill bit to turn in the chuck. Feeding too rapidly

might stop the motor, cause the belt to slip, force the workpiece loose, or break the drill bit. Practice with

scrap material to get the feel of the machine before attempting to do any drilling operation.

WARNING: To prevent the workpiece and the backup material from slipping from your hand

while drilling, position the workpiece and backup material to the left side of the column. If the

workpiece and the backup material are not long enough to reach the column, clamp the workpiece

and backup material to the table. Failure to do this could result in personal injury.

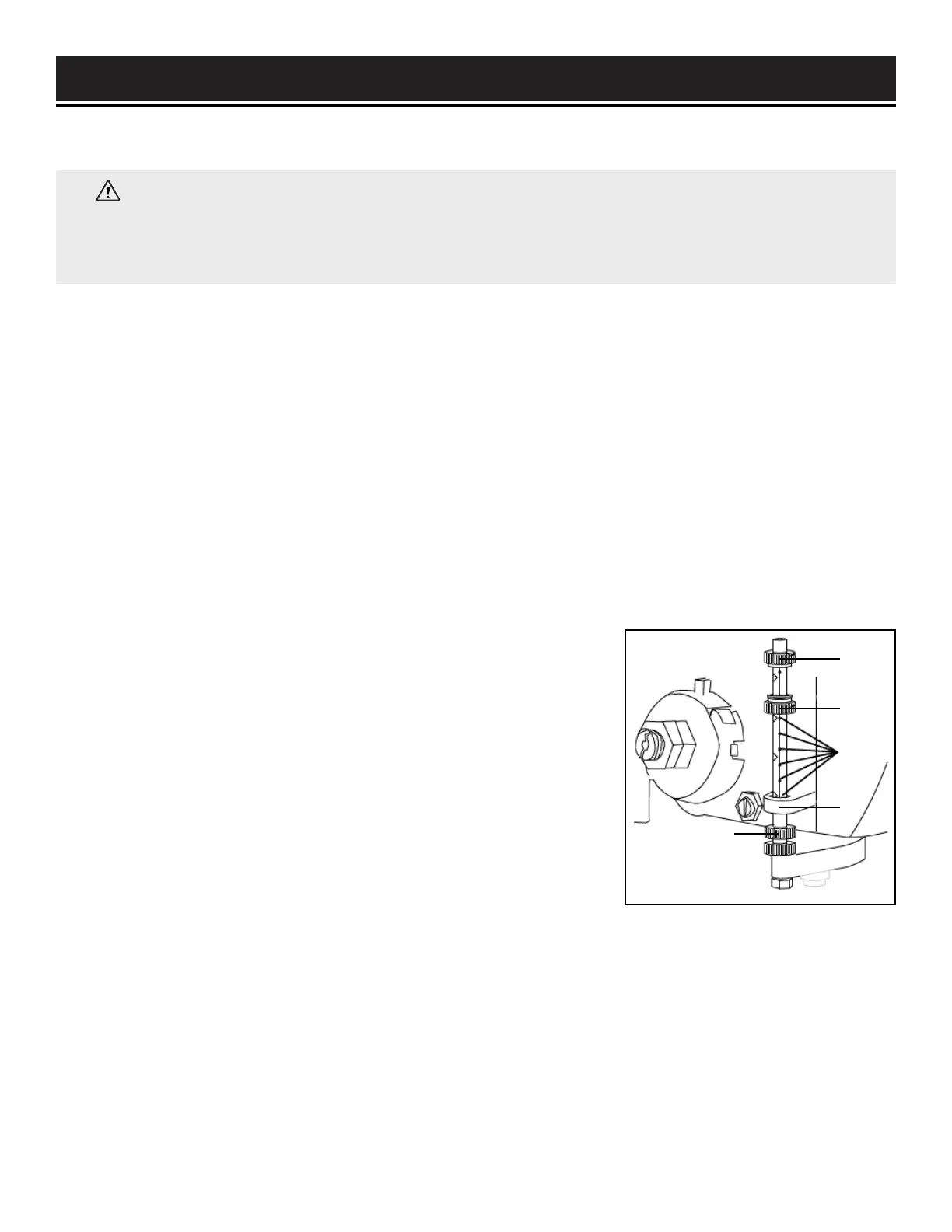

Fig. 21A

ADJUST THE DRILLING DEPTH (FIG. 21A)

The depth gauge controls the maximum distance the drill bit will

move up or down.

TO STOP THE DRILL BIT AT A PRE-MEASURED DEPTH:

1. Rotate the lower depth scale knob (Fig. 21A - 2) until the bottom

of the knob is aligned with the desired depth mark

(Fig. 21A - 5) on the gauge scale.

2. Rotate the depth scale lock knob (Fig. 21A - 1) until it meets the

lower depth scale knob (Fig. 21A - 2). The chuck will stop after

travelling downward to the selected distance.

TO ADJUST THE QUILL (RETURN) HEIGHT:

To adjust the upward distance the quill (shaft that moves up and down) can travel:

1. Turn the feed handles until the quill is at the desired height and hold it there.

2. Rotate the lower depth knob (Fig. 21A - 3) until it rests against the bottom of the metal gauge support

(Fig. 21A - 4).

Drilling an unmeasured blind hole (not all the way through the workpiece) to a given depth can be done two

ways: using the depth scale method or workpiece method.

4

5

2

1

3

19

Loading...

Loading...