OPERATION

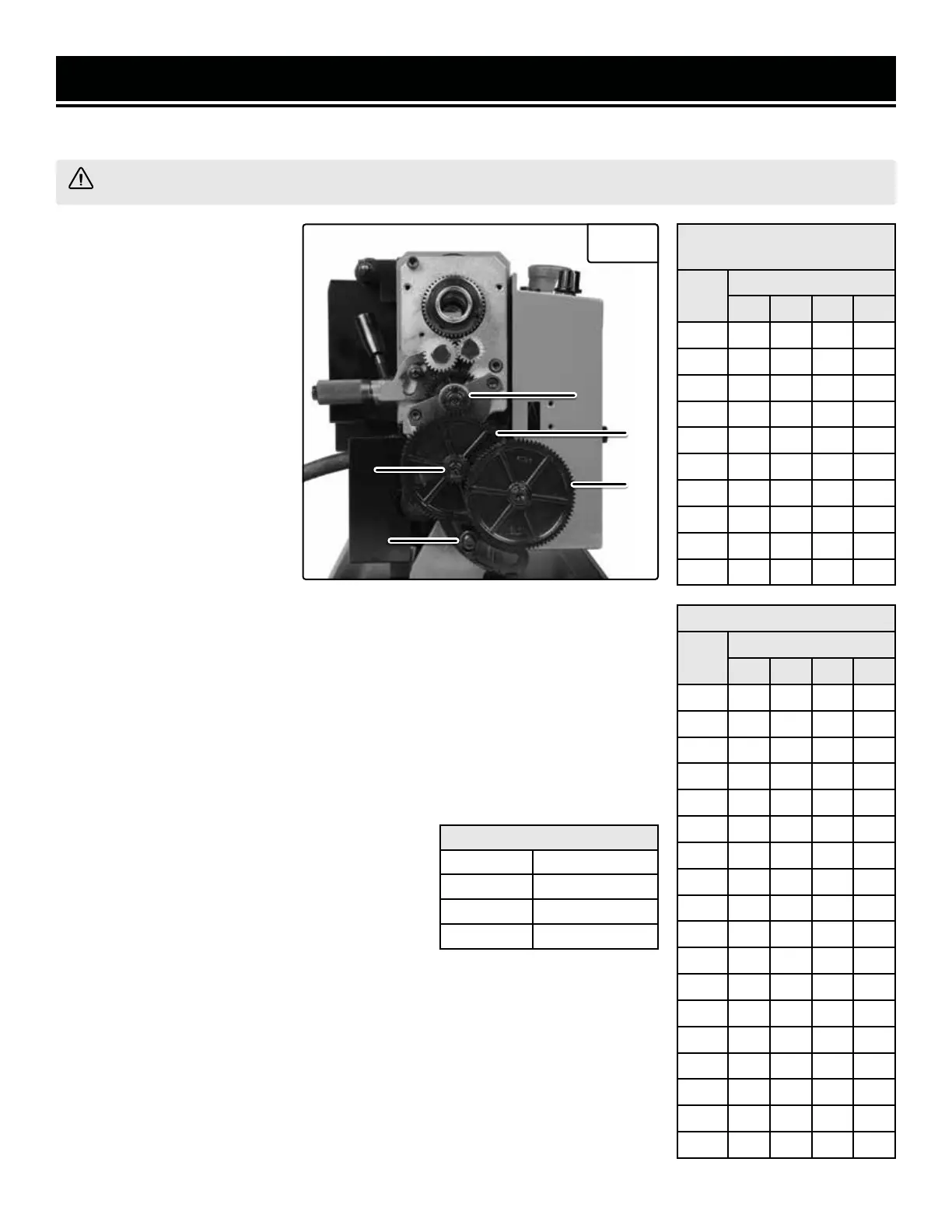

GEAR TRAIN

WARNING! Before making any of these adjustments, turn off and unplug the lathe from its power source.

NOTE: This lathe is designed

for use with plastic gears. This

is intentional, so that if you

make a mistake and a gear or

the lead screw binds up, a gear

will break, rather than the mo-

tor. The gears are much easier

and less expensive to replace.

The gear train is located on the

headstock opposite the spin-

dle. The drive gears are located

under a cover secured by two

socket head cap screws. The

gear train is used to drive the

lead screw’s speed, allowing

the auto-feed function to oper-

ate. As the gear train turns, it

Fig. 8

AAA

BBB

DDD

CCC

AdjusterAdjusterAdjuster

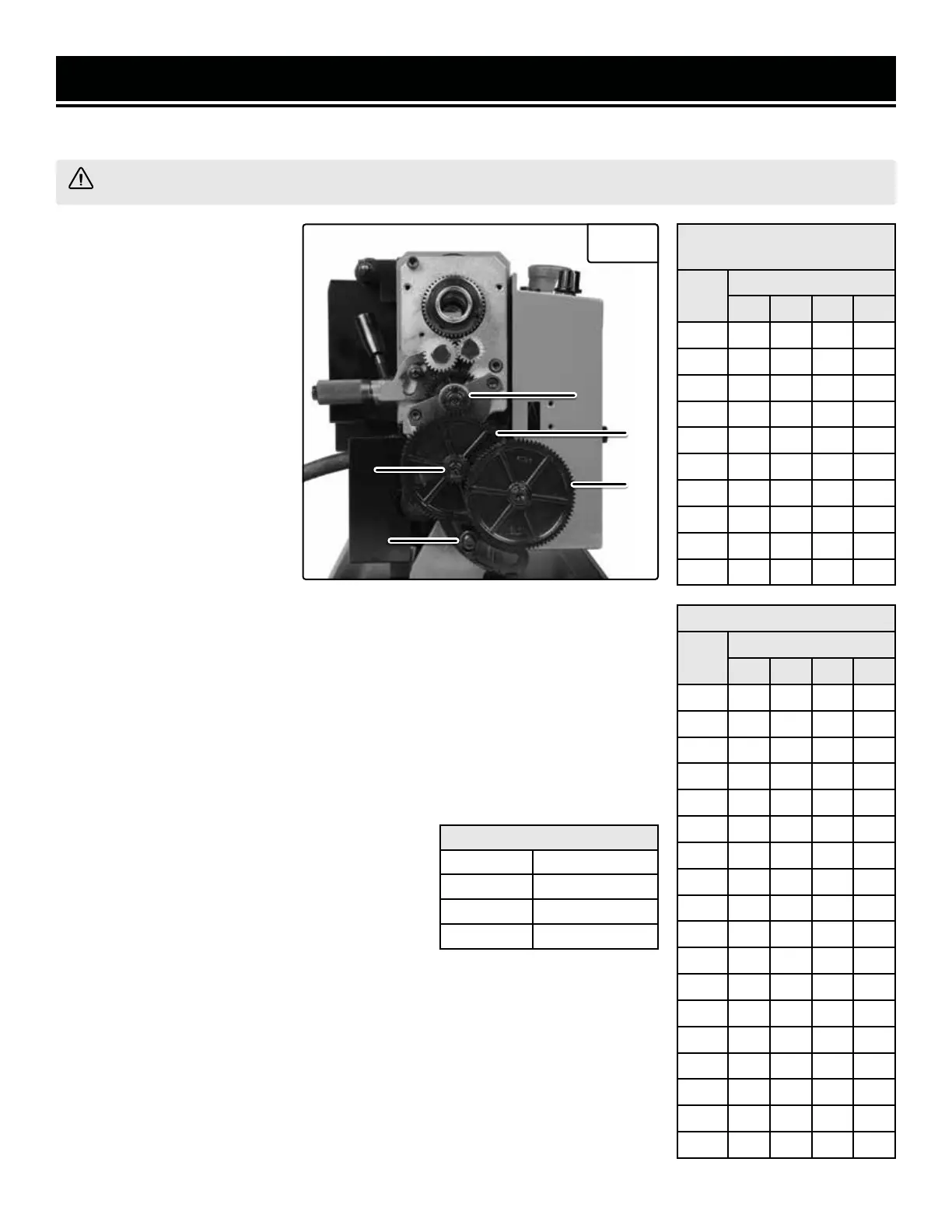

METRIC THREAD PITCH

CHART

Pitch

Gear Size (mm)

A B C D

0.4 20 50 40 60

0.5 20 50 / 60

0.6 40 50 30 60

0.7 40 50 35 60

0.8 40 50 40 60

1.0 20 60 / 30

1.25 50 40 / 60

1.5 40 60 / 40

1.75 35 60 / 30

2.0 40 60 / 30

THREADS PER INCH (TPI)

TPI

Gear Size (mm)

A B C D

12 40 65 / 30

13 40 65 60 30

14 40 65 / 35

16 40 65 / 40

18 40 65 / 45

19 40 50 60 57

20 40 65 / 50

22 40 65 / 55

24 40 65 / 60

26 40 60 / 65

28 20 65 / 35

32 20 65 / 40

36 20 65 / 45

38 20 50 60 57

40 20 65 / 50

44 20 65 / 55

48 20 65 / 60

52 20 60 / 65

turns the lead screw which moves the carriage across the bed of the lathe. The

direction is set using the lead screw direction lever. Adjusting it to forward will send

the carriage towards the headstock. Reverse sends it away, and neutral disengages

the lead screw so the carriage can be manually fed.

The feed rate of the lead screw can be set by changing the gears in the gear train

(Fig. 8). Switching the diameter of the gears and the order of the gears will change

the lead screw’s speed, allowing for different threads to be turned with the lathe.

The Threading Chart to the right shows the gear arrangements to use to achieve

different threads per inch (TPI) or metric pitches when using the lead screw.

FACTORY SETTINGS

A 20

B 80

C 20

D 80

To change the gears:

1. Using the 4mm hex wrench, remove the 2

mounting screws on the gear cover. Then remove

the gear cover.

2. Loosen the adjustment nut at the bottom of the

gear train to disengage the gears from one anoth-

er. Loosen the socket head cap screws that hold

each gear (or gear pair) on its shaft. Remove the necessary gears and replace them

with the appropriate gears. That is, the gears that have the proper number of teeth

in the positions called for (30, 40, 60, and 65 teeth). Note that some configurations

do not require gears in every position, and some require you to move the bushings

from one shaft to another for gears to properly fit in place.

3. Position the gears so their teeth will mesh together properly once the adjuster

is tightened.

15

Loading...

Loading...