OPERATION

BEVEL CUTTING

In order to perform a bevel cut, it is necessary to use the compound slide as well as the cross slide. To align the

compound slide for a bevel cut, align it to the proper angle following the procedure in the “Compound Slide” section

on page 12.

Once the compound slide is aligned to the proper angle, follow these steps to create the bevel:

1. Mark your end point of the bevel if necessary, using the methods for a normal turning.

2. Set and zero out the cross slide to the proper starting point.

3. Turn the lathe on and set the spindle to the appropriate RPM.

4. Use the handle on the compound slide to feed the cutting tool along the end of the workpiece. This will create the

bevel cut at the angle you set it to.

5. Back off the cutting tool 2 turns and reset the compound slide to the starting point. Feed the cutting tool back in

to the cutting depth.

6. Repeat until your bevel is the desired length and position.

TO CUT THREADS

1. Adjust the compound slide so the tool is at the appropriate angle for the desired

thread.

2. Place the tool tip so that it is vertically centered and perpendicular to the work-

piece.

3. Engage the thread dial with the lead screw. The thread dial is located next to

the auto-feed lever on the carriage. There is a socket-head cap screw on the side;

loosen the screw using one of the included hex wrenches and adjust the body of the

thread dial so that its gear meshes with the threads on the lead screw. Tighten the

socket head cap screw, ensuring that the gear stays engaged with the lead screw

threads.

4. Use the gear ratio charts to determine the proper gear ratio and install the proper

gears (See “Gear Train” on page 15).

5. Turn the lathe on and set the RPM using the speed control knob. Make sure the

lead screw is feeding in the proper direction by engaging the feed lever. When you

are sure it is going in the right direction disengage the feed lever and turn off the

lathe. Ensure that the carriage is beyond the end of the workpiece.

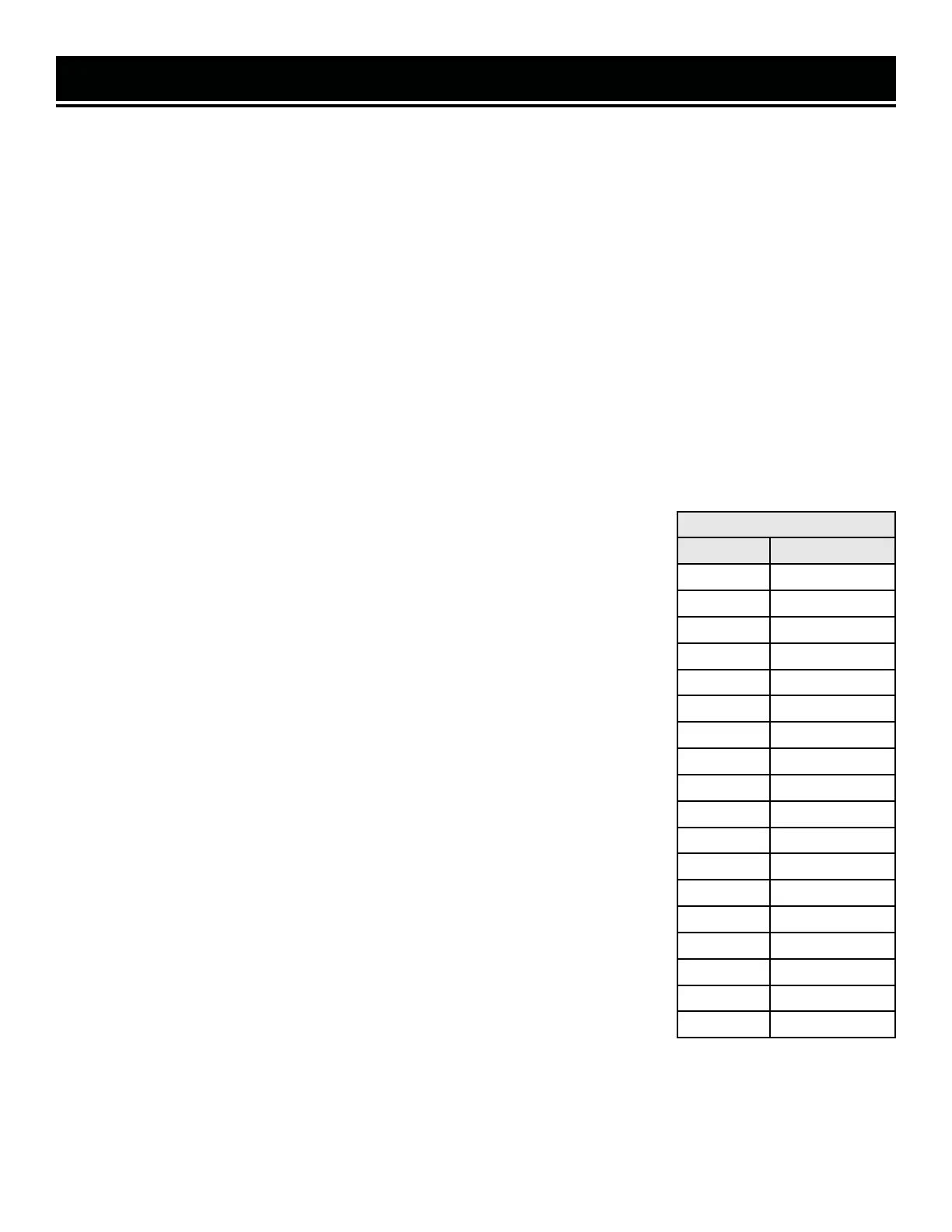

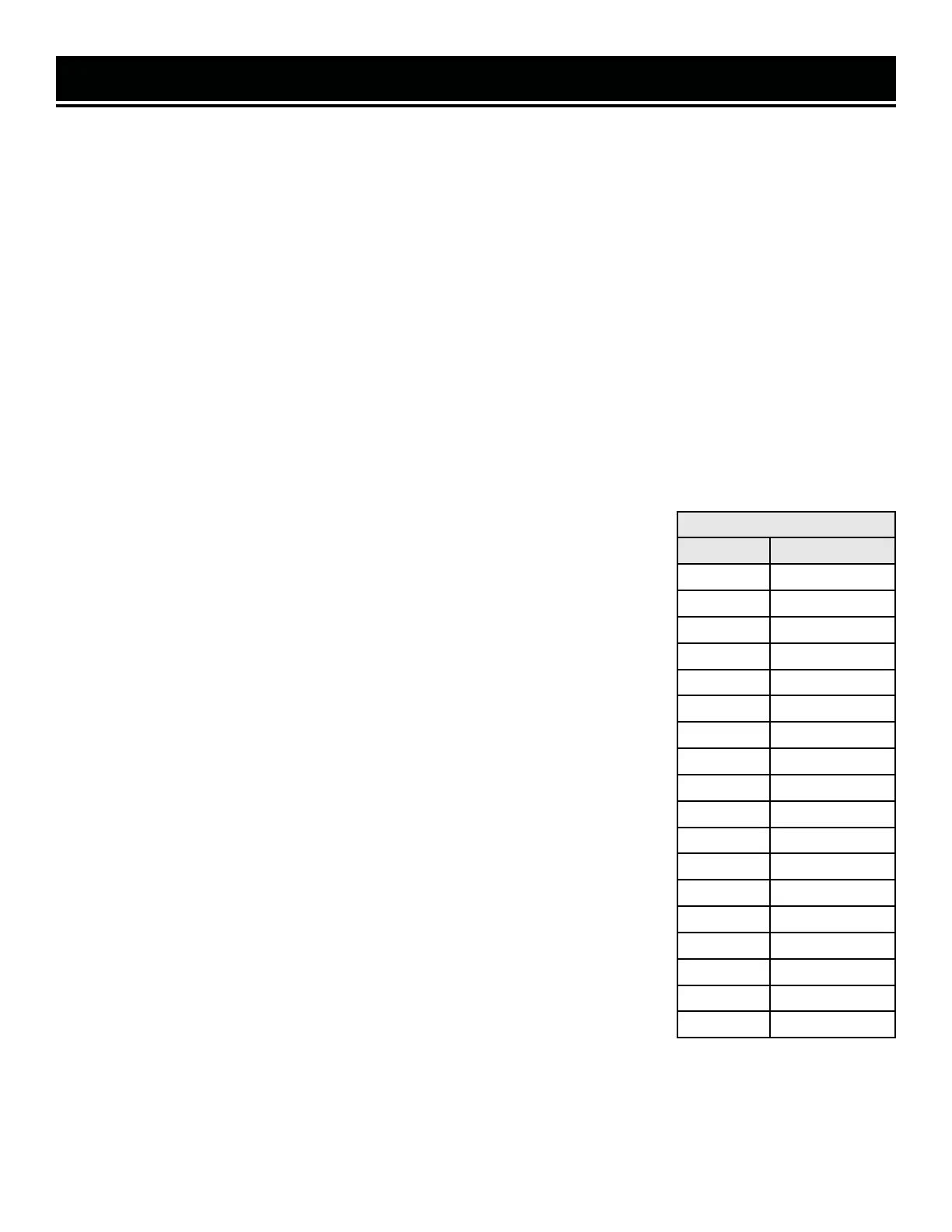

6. Read the settings off the thread dial chart (left) to get the proper setting for the

thread dial. Make sure the thread dial always engages the half nut on the same mark

for every pass of the cutting tool. If you don’t do this, you may cut off threads cre-

ated in your previous cut. That is, the lever needs to be pushed down at the same

point in order to cut threads correctly. If you engage the lever when the dial is not

pointing to an indicator mark, you may stall the lead screw, which will cause it to

drop into Neutral and stop.

THREAD DIAL

TPI

SCALE

12 1, 3, 5, 7

13 1

14 1 or 5

16 1 - 8

18 1 or 5

19 1

20 1, 3, 5, 7

22 1 or 5

24 1 - 8

26 1 or 5

28 1, 3, 5, 7

32 1 - 8

36 1, 3, 5, 7

38 1 or 5

40 1 - 8

44 1, 3, 5, 7

48 1 - 8

52 1, 3, 5, 7

18

Loading...

Loading...