Starting and operating Chapter 5

Chapter 5Chapter 5

Chapter 5

16.05.17 Working Instructions WIDOS MAXIPLAST Page 19 of 41

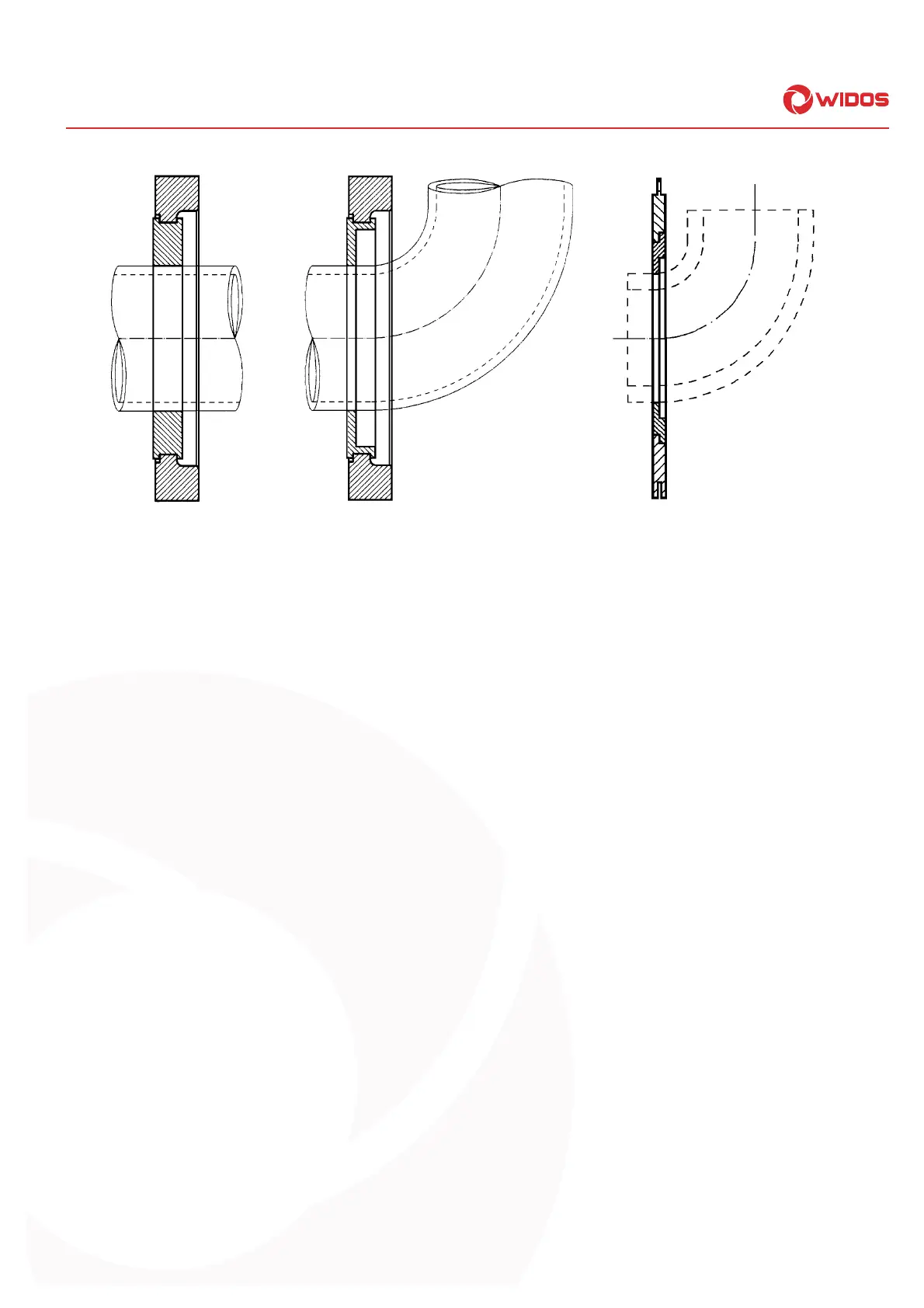

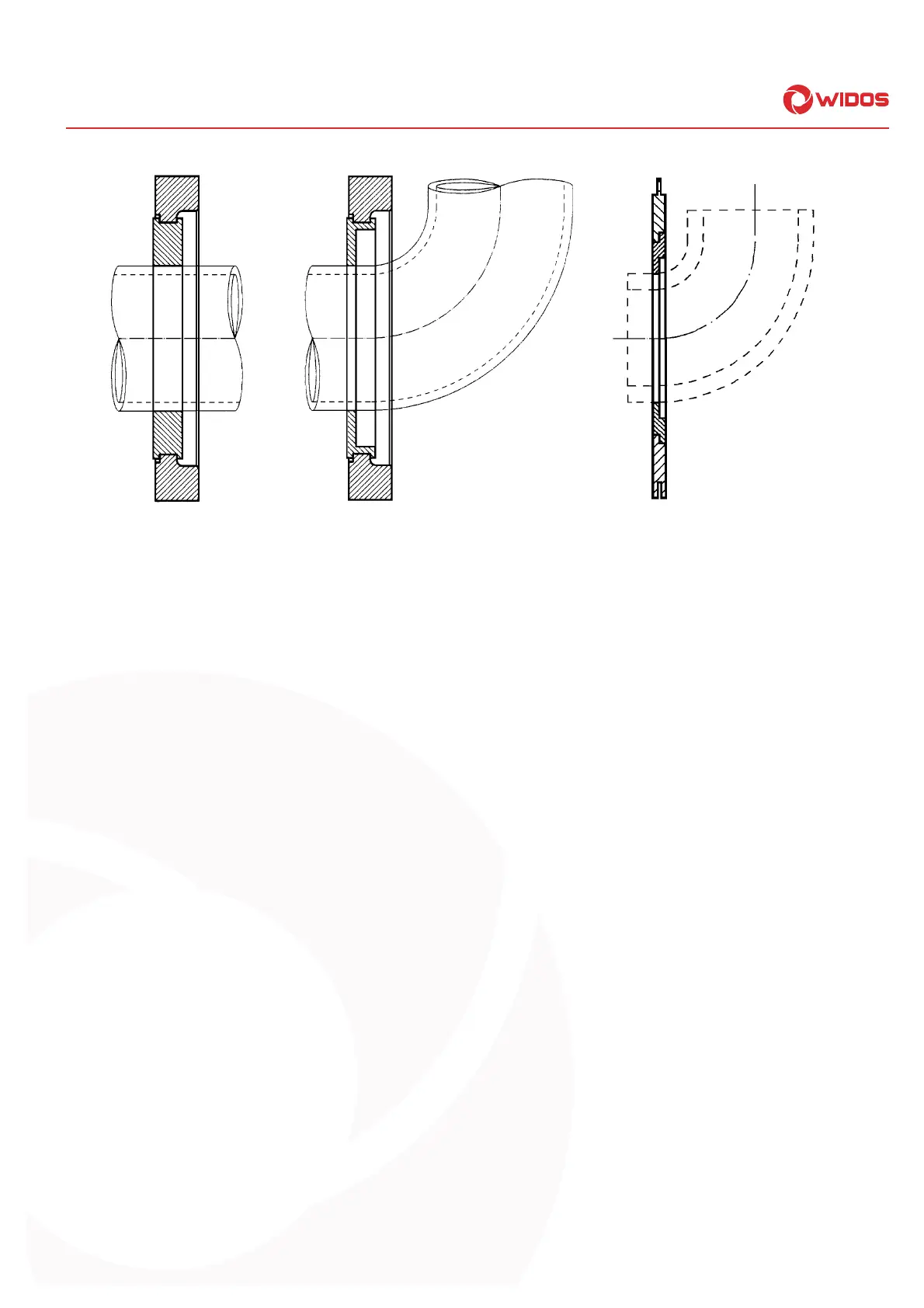

wide clamping tool wide clamping tool fitting clamping tool

(fitting reduction insert, optional) (optional)

5.2.

5.2.5.2.

5.2. Welding process

Welding processWelding process

Welding process

I n p r i n c i p l e , t h e v a l i d w e l d i n g r e g u l a t i o n s ( I S O / C E N / D V S . . . ) a r e t o b e

I n p r i n c i p l e , t h e v a l i d w e l d i n g r e g u l a t i o n s ( I S O / C E N / D V S . . . ) a r e t o b eI n p r i n c i p l e , t h e v a l i d w e l d i n g r e g u l a t i o n s ( I S O / C E N / D V S . . . ) a r e t o b e

I n p r i n c i p l e , t h e v a l i d w e l d i n g r e g u l a t i o n s ( I S O / C E N / D V S . . . ) a r e t o b e

o b s e r v e d .

o b s e r v e d .o b s e r v e d .

o b s e r v e d .

• Put on safety gloves to protect you from being burned.

• A stop-watch should be available in order to be able to register the actual times for heating up and

cooling down.

• A table should be available from which you can read the parameters that are prescribed by the

welding regulation for the pipe diemesion to be welded.

• The heating elements are to be clean and, above all, free from grease. Therefore they are to be

cleaned with non-fraying paper and detergent (e.g. technically pure alcohol or pipe-cleansing

cloths which can be bought at the WIDOS company) before every welding or if they are dirty.

The anti-adhesive coating of the heating element has to remain undamaged in the working area.

• Switch on heating element and set the required welding temperature on the adjustment screw on

the handle.

• If the control light flashes, the nominal temperature has been reached and is held at a constant

level through a given impulse-break relationship.

• Screw in reduction inserts according to the outer diameter of the pipes to be welded, if necessary

set the angle.

Loading...

Loading...