Foundation: 2207, 2208, DIN 16932 German association for welding

Miniplast 2 / 110

Miniplast 2 / 110Miniplast 2 / 110

Miniplast 2 / 110

Maxiplast / 501 / 900 / 955

Maxiplast / 501 / 900 / 955Maxiplast / 501 / 900 / 955

Maxiplast / 501 / 900 / 955

Instaweld 160

Instaweld 160Instaweld 160

Instaweld 160

2000 / 3000 Kombi

2000 / 3000 Kombi2000 / 3000 Kombi

2000 / 3000 Kombi

2500 DO 160 / 250 / 315

2500 DO 160 / 250 / 3152500 DO 160 / 250 / 315

2500 DO 160 / 250 / 315

ASM160 / ASM 315

ASM160 / ASM 315ASM160 / ASM 315

ASM160 / ASM 315

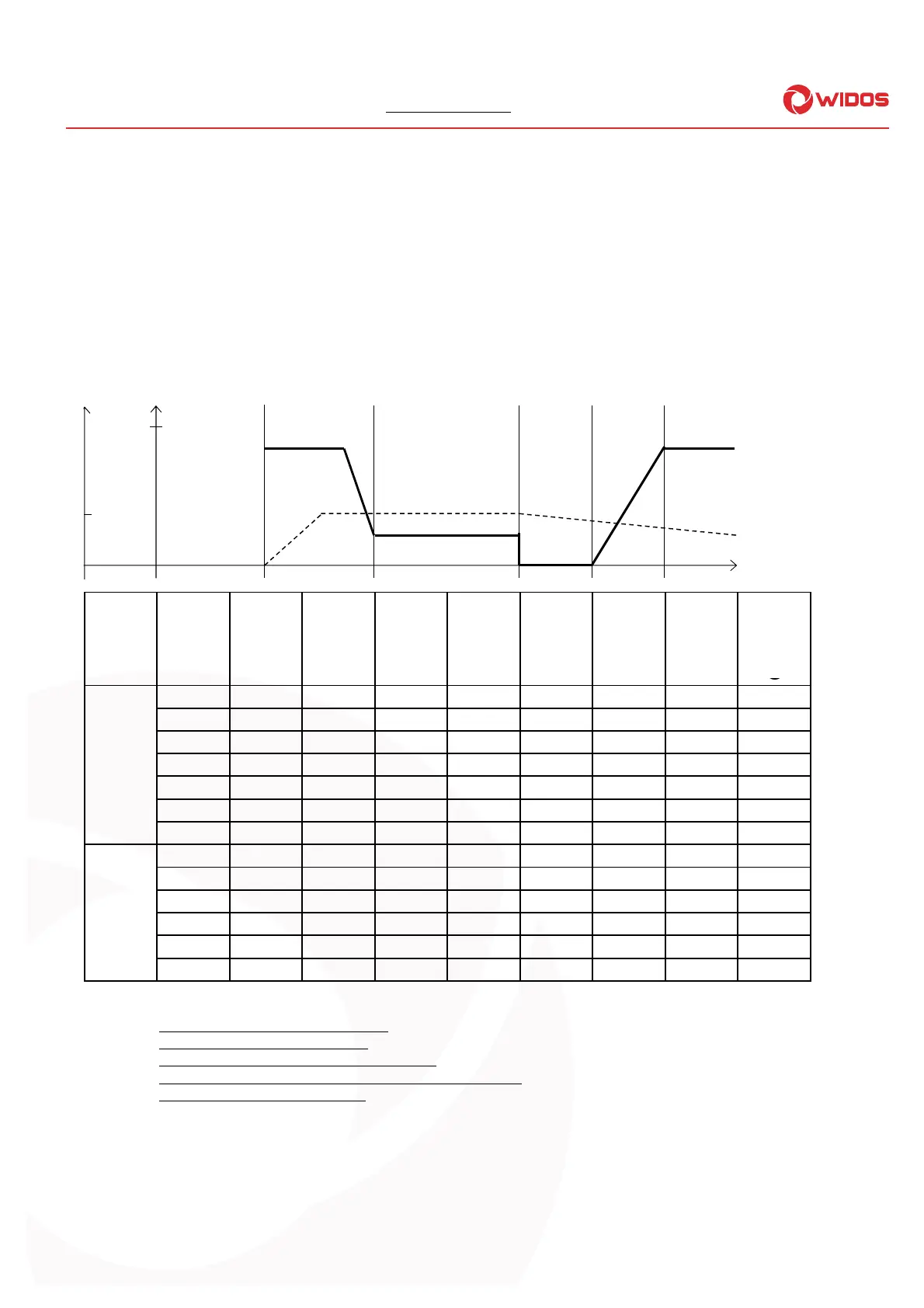

time to

time totime to

time to

change-

change-change-

change- reach full

reach fullreach full

reach full

over

overover

over welding

weldingwelding

welding cool-down time

cool-down timecool-down time

cool-down time

0,10 (PP) time

timetime

time pressure

pressurepressure

pressure

pressure in

T

desired

temperature

time

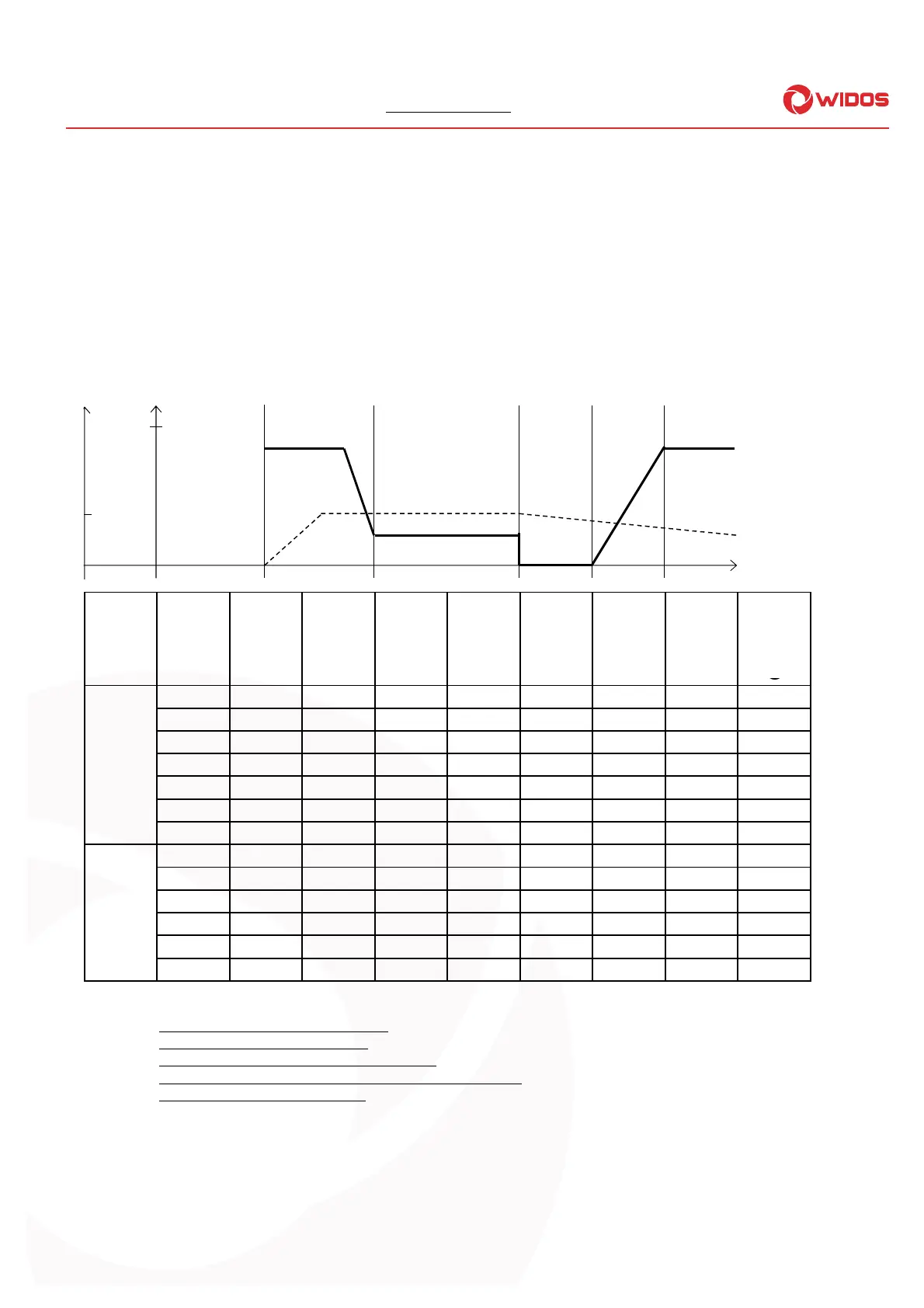

Table for PP

Table for PPTable for PP

Table for PP

The standard value for heating element temperature is 210° C +/- 10° C.

The

smaller

smallersmaller

smaller

the pipe wall the

welding area

in welding area

P (N/mm²)

bead-up

bead-upbead-up

bead-up heat-up

heat-upheat-up

heat-up

Additional to the given bead-up force and to the welding force the moving force of the support must be added !

Remaining under the cool-down time for up to 50% is allowed under the following conditions:

Remaining under the cool-down time for up to 50% is allowed under the following conditions:Remaining under the cool-down time for up to 50% is allowed under the following conditions:

Remaining under the cool-down time for up to 50% is allowed under the following conditions:

prefabrication under workshop conditions

low additional pressure at unclamping

no additional pressure during further cooling down

load onto the workpieces only after being completely cooled down

Join parts with wall thickness

16.05.2017 Working instructions WIDOS manual machine Page 25 / 8 of 41

Loading...

Loading...