Disassembly / Reassembly

Pump Disassembly

Tools Required:

•

9/16" Socket Wrench

•

1-1/8" Socket Wrench

•

3/4" Socket Wrench

•

11/16" Socket Wrench

•

3/4" Combo Wrench

CAUTION:

Before any maintenance or repair is attempted, the compressed air

line to the pump should be disconnected and all air pressure allowed to bleed

from the pump. Disconnect all intake, discharge and air lines. Drain the pump

by turning it upside down and allowing any fluid to flow into a suitable container.

Be aware of any hazardous effects of contact with your process fluid.

NOTE:

Replace worn parts with genuine Wilden parts for

reliable performance.

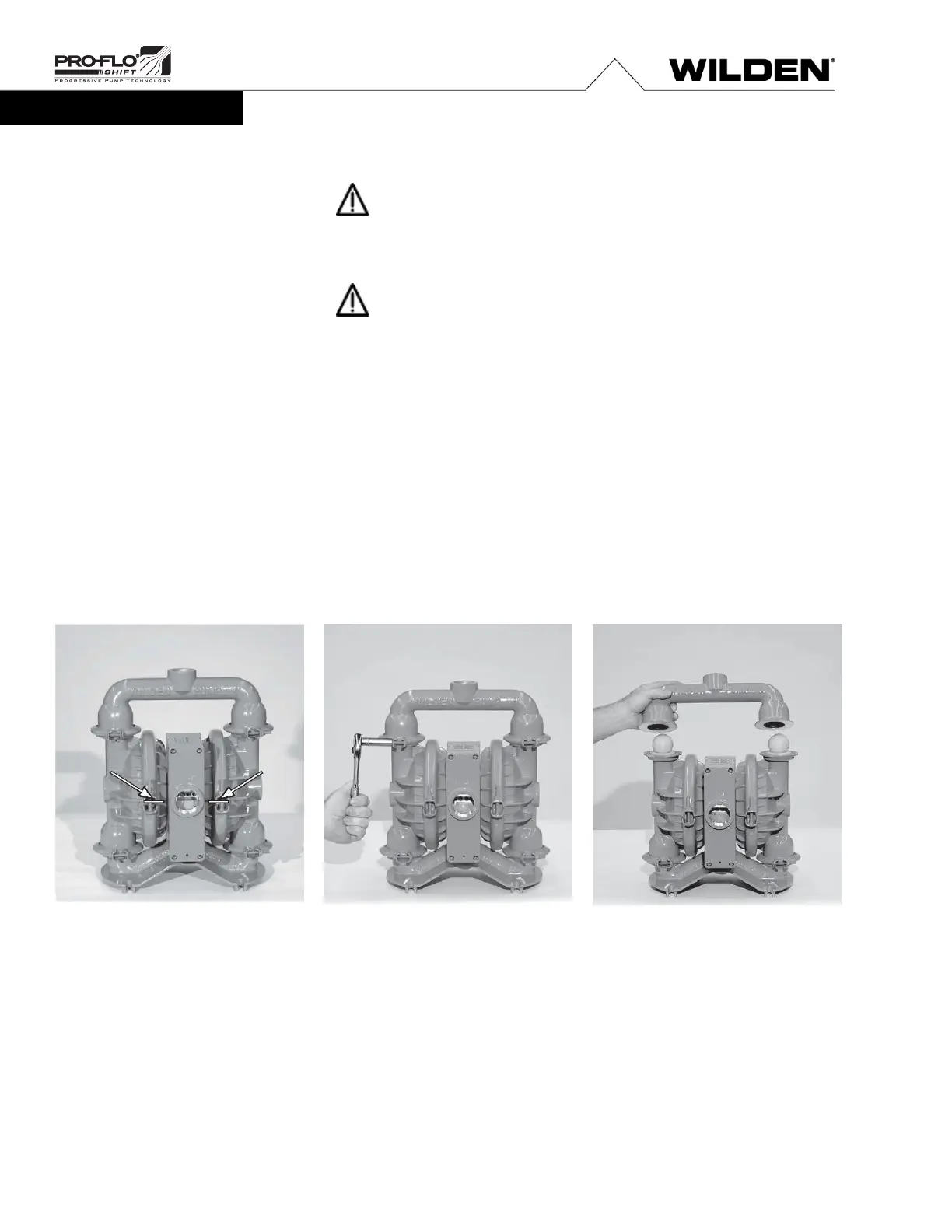

Step 1

Before starting disassembly, mark a line

from each liquid chamber to its

corresponding air chamber. This line will

assist in proper alignment during

reassembly.

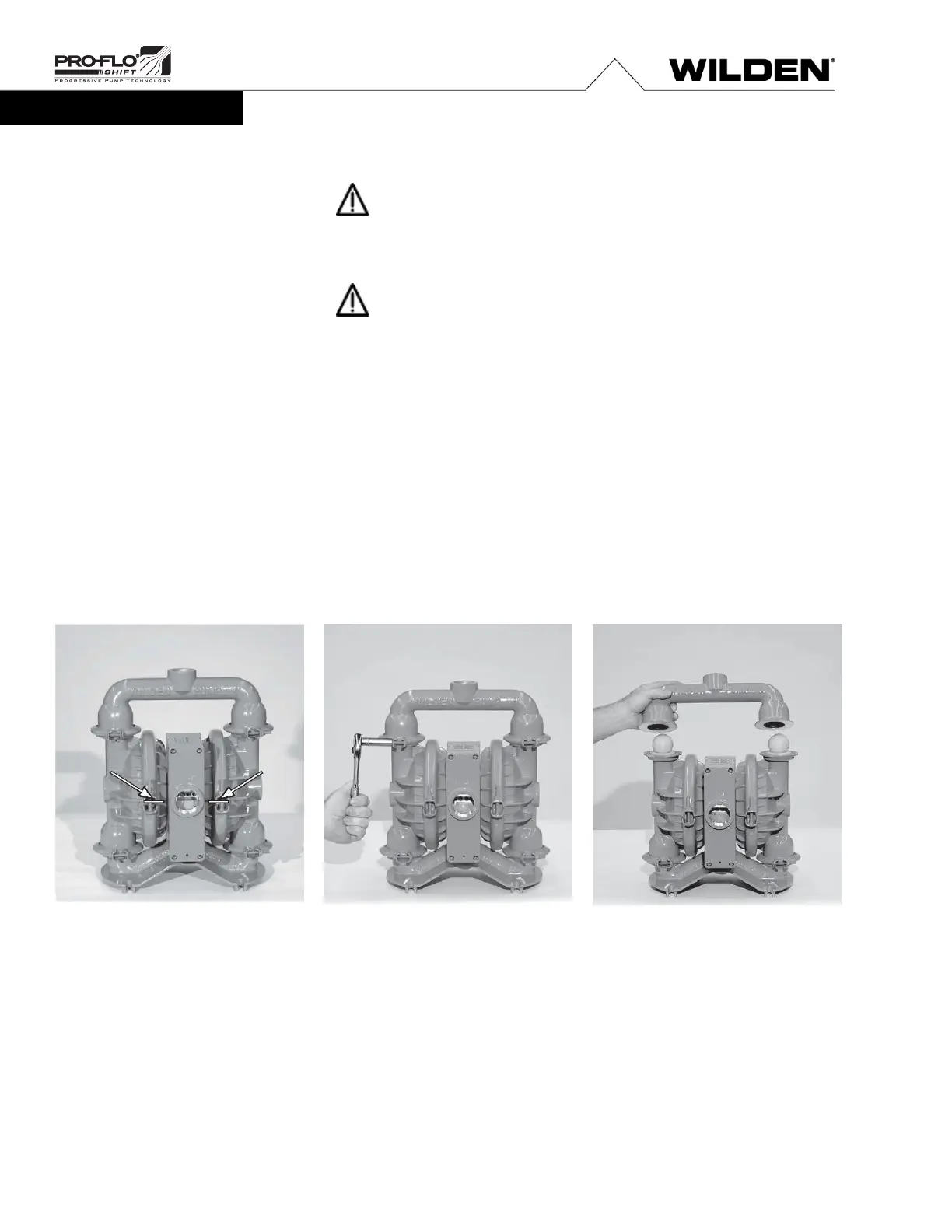

Step 2

Using an appropriate-sized wrench, remove

the two (2) small clamp bands that fasten

the discharge manifold to the liquid

chambers

.

Step 3

Lift the discharge manifold to expose

discharge valve balls and valve seats.

Inspect ball cage area of manifold for

excessive wear or damage

.

Loading...

Loading...