Disassembly / Reassembly

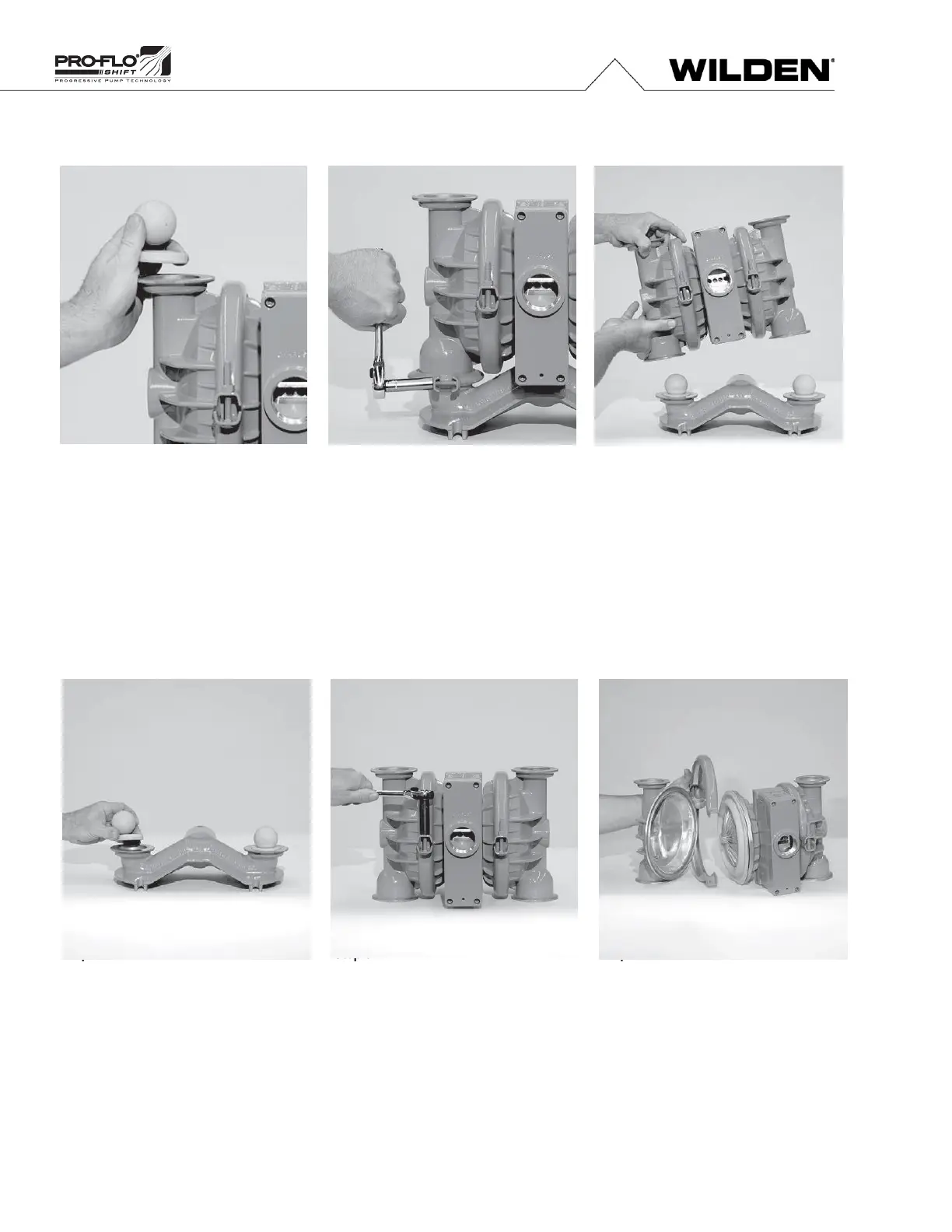

Step 4

Remove the discharge valve balls

and valve seats from the liquid

chambers and inspect for nicks,

chemical attack or abrasive wear.

Replace worn parts with genuine

Wilden parts for reliable performance.

Step 5

Using an appropriate-sized wrench,

remove the two (2) small clamp

bands that fasten the inlet manifold to

the liquid chambers.

Step 6

Lift the liquid chambers and center section

assembly from the inlet manifold to expose the

inlet valve balls and valve seats. Inspect ball

cage area of inlet manifold for excessive wear

or damage.

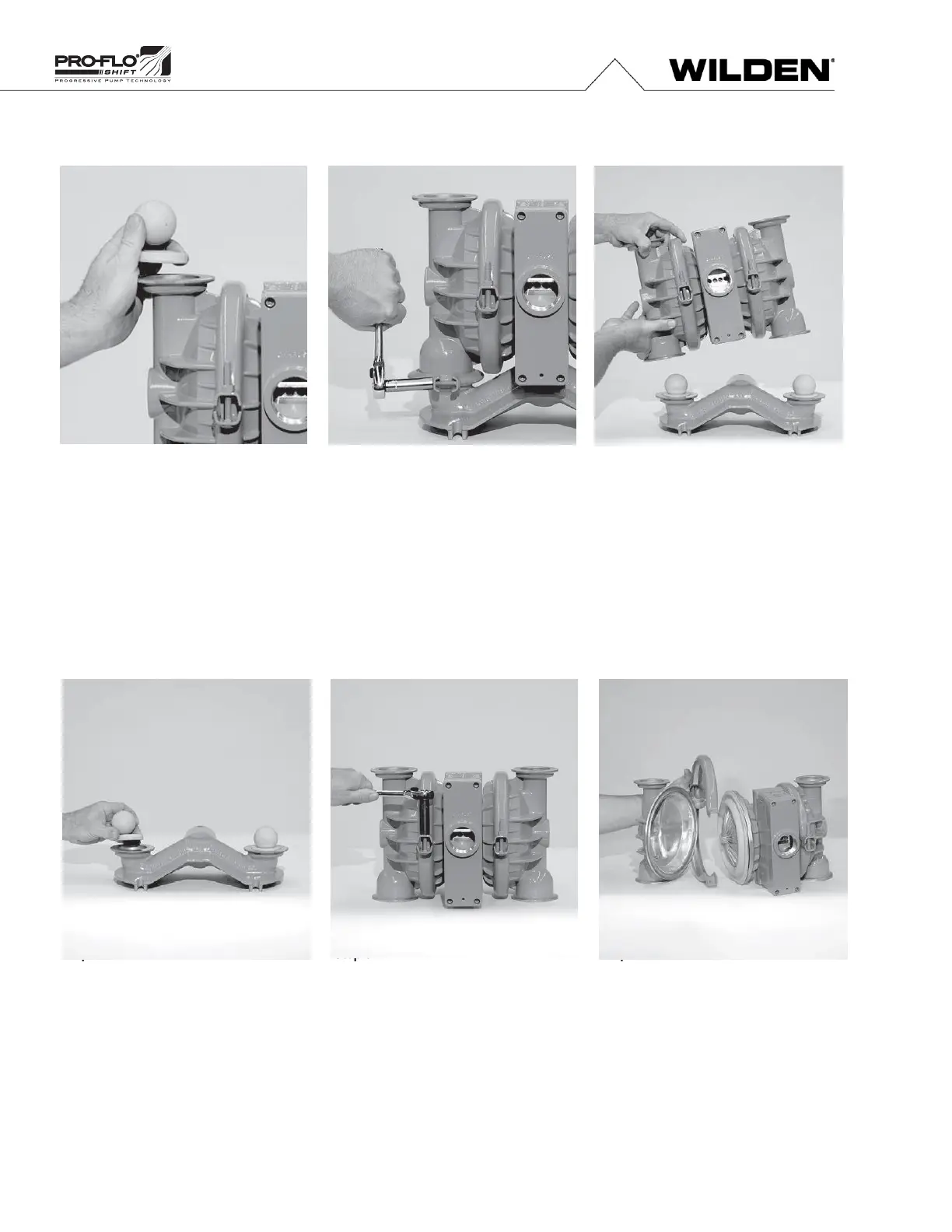

Step 7

Remove the inlet valve balls and valve

seats from the inlet manifold and inspect

for nicks, chemical attack or abrasive

wear. Replace worn parts with genuine

Wilden parts for reliable performance.

Step 8

Using an appropriate-sized wrench, remove

one set of large clamp bands that secure

one liquid chamber to the center section.

Step 9

Pull liquid chamber away from the center

section to expose diaphragm and outer piston.

Remove other side of the liquid chamber from

center section..

Loading...

Loading...