PS15 METAL

RUBBER-FITTED

Ship Weight ........ Aluminum 55 kg (121 lb)

316 Stainless Steel 105 kg (230 lb)

Cast Iron 93 kg (205 lb)

Air Inlet................................................ 3/4"

Inlet ..................................................... 3

"

Outlet .....................................................

3

"

Suction Lift ....................6.6 m Dry (21.6

'

)

8.6 m Wet (28.4')

Disp. Per Stroke

1

................ 5.2 L (1.38 gal)

Max. Flow Rate .......... 927 lpm (245 gpm)

Max. Size Solids ................... 9.5 mm (3/8")

1Displacement per stroke was calculated

at 4.8 bar (70 psig) air inlet pressure

against a 2.1 bar (30 psig) head pressure.

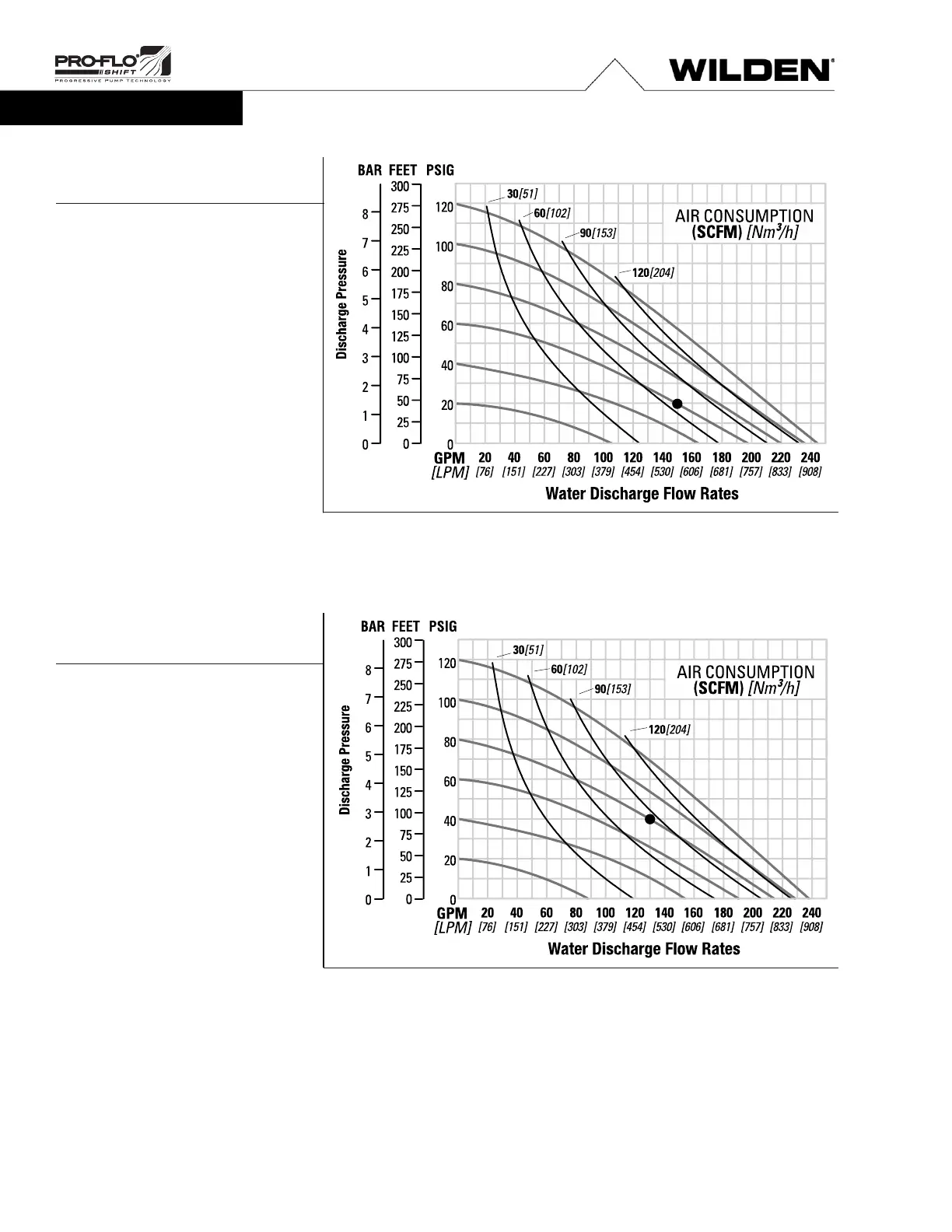

Example:

To pump 568 lpm (150 gpm)

against a discharge head of 1.4 bar

(20 psig) requires 4.1 bar (60 psig) and

116 Nm3/h (68 scfm) air consumption.

Caution: Do not exceed 8.6 bar (125 psig)

air supply pressure.

Flow rates indicated on chart were determined by pumping water.

For optimum life and performance, pumps should be specified so that daily

operation parameters will fall in the center of the pump's performance curve.

PS15 METAL

EZ-INSTALL TPE-FITTED

Ship Weight Aluminum 55 kg (121 lb)

316 Stainless Steel 105 kg (230 lb)

Cast Iron 93 kg (205 lb)

Air Inlet................................................ 3/4"

Inlet ..................................................... 3

"

Outlet .....................................................

3

"

Suction Lift ................... 6.3 m Dry (20.7

'

)

8.6 m Wet (28.4

'

)

Disp. Per Stroke

1

................... 5.3 L (1.41 gal)

Max. Flow Rate .......... 901 lpm (238 gpm)

Max. Size Solids ................... 9.5 mm (3/8

"

)

1

Displacement per stroke was calculated

at 4.8 bar (70 psig) air inlet pressure

against a 2.1 bar (30 psig) head pressure.

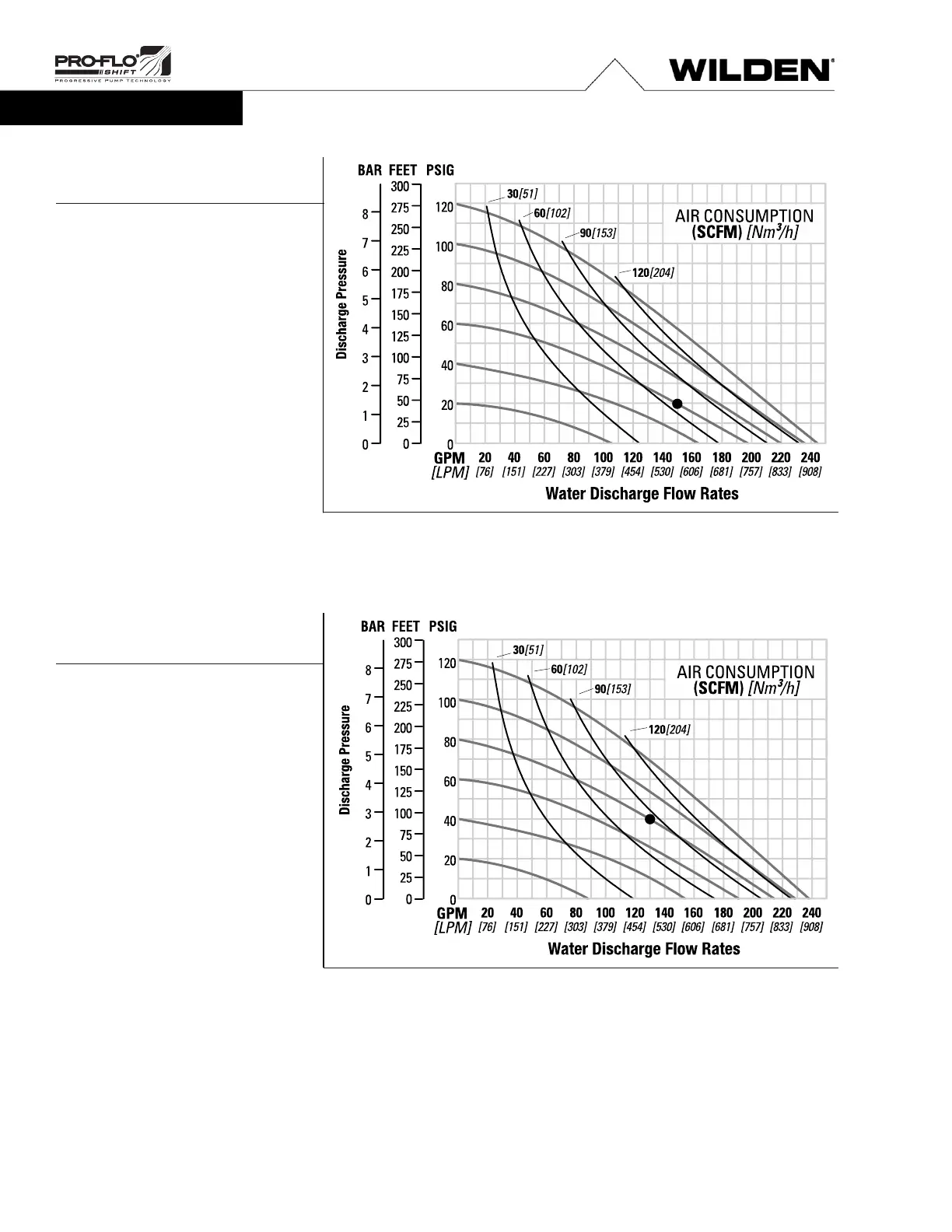

Example:

To pump 492 lpm (130 gpm)

against a discharge head of 2.8 bar

(40 psig) requires 5.5 bar (80 psig) and

144 Nm3/h (85 scfm) air consumption.

Caution: Do not exceed 8.6 bar (125 psig)

air supply pressure.

Loading...

Loading...