20

Part Number 550-142-785/0812

GWI

Series 2 Gas-Fired Water Boilers – Boiler Manual

❏ Boilerandheatdistributionunitslledwithwater?

❏ Automaticairvent,ifused,openonefullturn?

❏ Airpurgedfromsystem?

❏ Airpurgedfromgaspiping?Pipingcheckedforleaks?

❏ Correctly-sized manifold orices installed? See Table 3,

page 6tochecksizeandfueltype.

Correctly sized manifold orices must be used.

Failure to do so will cause severe personal injury,

death or substantial property damage.

❏ Followed“Operatinginstructions”onboilerorinmanual,page

26forproperstart-up?

❏ Properburnerameobserved?See“Verifyoperation”,manual

Section 7.

❏ Test temperature limit — While burners are operating, turn

BoilerTempadjustmentknobcounterclockwiseuntildisplay

reading is below actual boiler water temperature. Burners

should go off while circulator continues to operate.Turn

BoilerTempadjustmentknobclockwiseuntildisplayread-

ingisaboveboilerwatertemperatureandignitionsequence

should resume.

❏ Test additional eld-installed controls—Ifboiler has a low

water cutoff, additional high limit or other controls, test for

operation as outlined by manufacturer. Burners should be

operatingandshouldgooffwhencontrolsaretested.When

controls are restored, burners should reignite.

❏ Testignitionsystemsafetydevice:

a. Connectmanometertooutletsideofgasvalve.Startboiler,

allowingfornormalstart-upcycletooccurandmainburn-

erstoignite.Withmainburnerson,manuallyshutoffgas

supplyatmanualmainshutoffgasvalve.Burnersshould

gooff.Openmanualmainshutoffgasvalve.Manometer

should confirm there is no gas flow. Pilot will relight, flame

sensing element will sense pilot flame and main burners

reignite.

❏ Setlimitcontrol(s)tosystemtemperaturerequirements.Adjust

balancing valves and controls to provide design temperature

to system.

❏

SetEconomymode,fullyclockwise.

❏ For multiple zones, adjust flow so it is about the same in each zone.

❏ Verifythermostatheatanticipator(ifavailable)setproperly?

See wiring diagram label on boiler or in manual, page 24 and

25.

❏ Cycleboilerwiththermostat—Raisetohighestsettingand

verify boiler goes through normal start-up cycle. Lower to

lowestsettingandverifyboilergoesoff.

❏

CycleDHWAquastatifused.

❏ Measurenaturalgasinput:

a. Operate boiler 10 minutes.

b. Turnoffotherappliances.

c. Atnaturalgasmeter,measuretime(inseconds)required

touseonecubicfootofgas.

d. Calculategasinput:

number of seconds from step c

= Btuh

e. Btuhcalculatedshouldapproximateinputratingonboiler

8 Checkout procedure

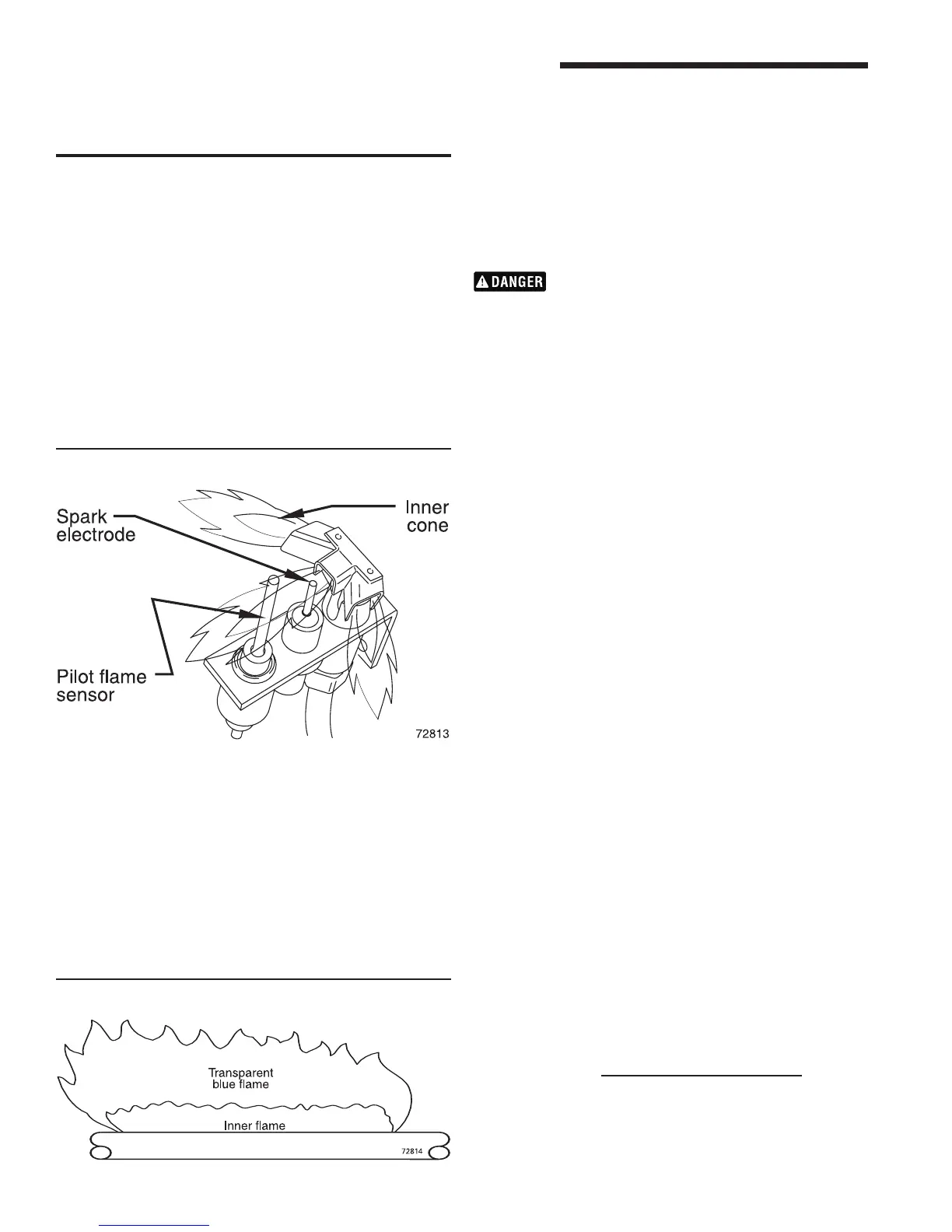

Check burner flame — Pilot burner

Proper pilot flame (see Figure 16):

1. Blue flame.

2. Innerconeengulngpilotamesensor.

3. Pilot flame sensor glowing cherry red.

Improper pilot flame:

1. Overred — Large ame lifting or blowingpast pilot ame

sensor.

2. Underred—Smallame.Innerconenotengulngpilotame

sensor.

3. Lackofprimaryair—Yellowametip.

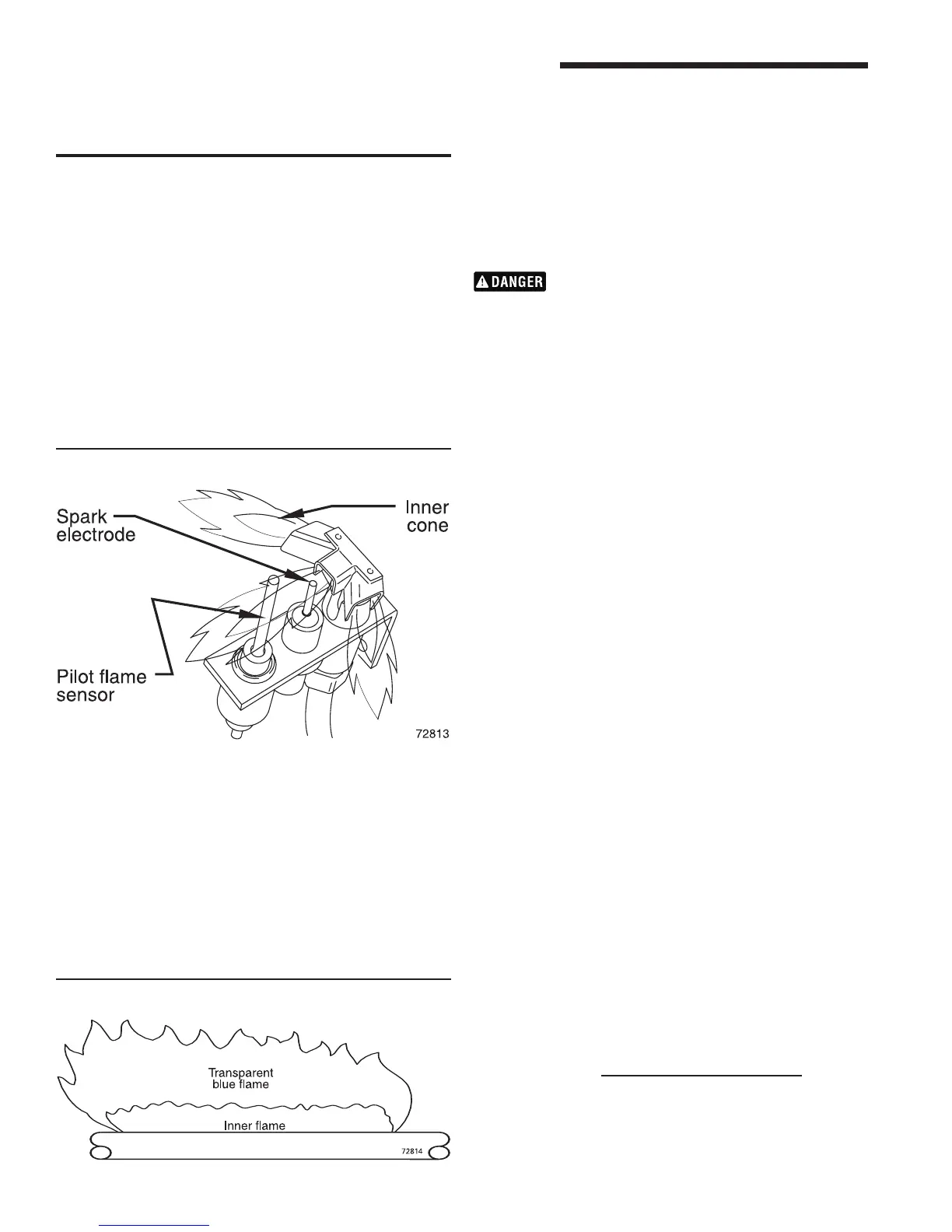

Figure 17 Typical main burner ame

Verify operation

Figure 16 Typical pilot burner ame

4. Incorrectlyheatedpilotamesensor.

Check burner flames — Main burner

Proper main burner flame (see Figure 17):

1. Yellow-orangestreaksmayappear(causedbydust).

Improper main burner flame:

1. Overred—Largeames.

2. Underred—Smallames.

3. Lackofprimaryair—Yellowtippingonames(sootingwill

occur).

7 Start-up continued

Loading...

Loading...