31

Part Number 550-142-785/0812

GWI

Series 2 Gas-Fired Water Boilers – Boiler Manual

12 Troubleshooting

Labelallwirespriortodisconnectionwhenservic-

ing controls. Wiring errors can cause improper and

dangerous operation.

Neverjumper(bypass)rolloutthermalfuseelement

oranyotherdeviceexceptformomentarytestingas

outlinedin“Troubleshooting”charts,pages 34 - 40.

Severe personal injury, death or substantial property

damage can result.

Burner access panel must be in position during

boiler operation to prevent momentary flame rollout

onignitionofmainame.Severepersonalinjuryor

substantial property damage will result.

Before troubleshooting:

1. Havethefollowingitems:

a. Voltmeterthatcancheck120VACand24VAC.

b. Microammeterwithaminimumscalerangeof0-25.

c. Continuitychecker.

d. U-tubemanometer

e. Inclinedmanometerwith0–2”w.c.range.

2. Checkfor120VAC(minimum102VACtomaximum132VAC)

to boiler.

3. Makesurethermostatiscallingforheatandcontacts(includ-

ingappropriatezonecontrols)areclosed.Checkfor24VAC

between thermostat wire nuts and ground.

Check the following:

1. Wire connectors to control module are securely plugged in at

module and originating control.

2. Gaspressures(connectU-tubemanometeratgasvalvetap-

pings):

a. Withboileroff—13”w.c.maximumnaturalorpropane

gaspressureupstreamofgasvalve.

b. With boiler on:

• 5”w.c.minimumnaturalgaspressureor11”w.c.propane

gaspressureupstreamofgasvalve.

• 3.5”w.c.minimumnaturalgaspressureor10”w.c.propane

gaspressuredownstreamtappingongasvalve—Can

be adjusted by regulator on gas valve.

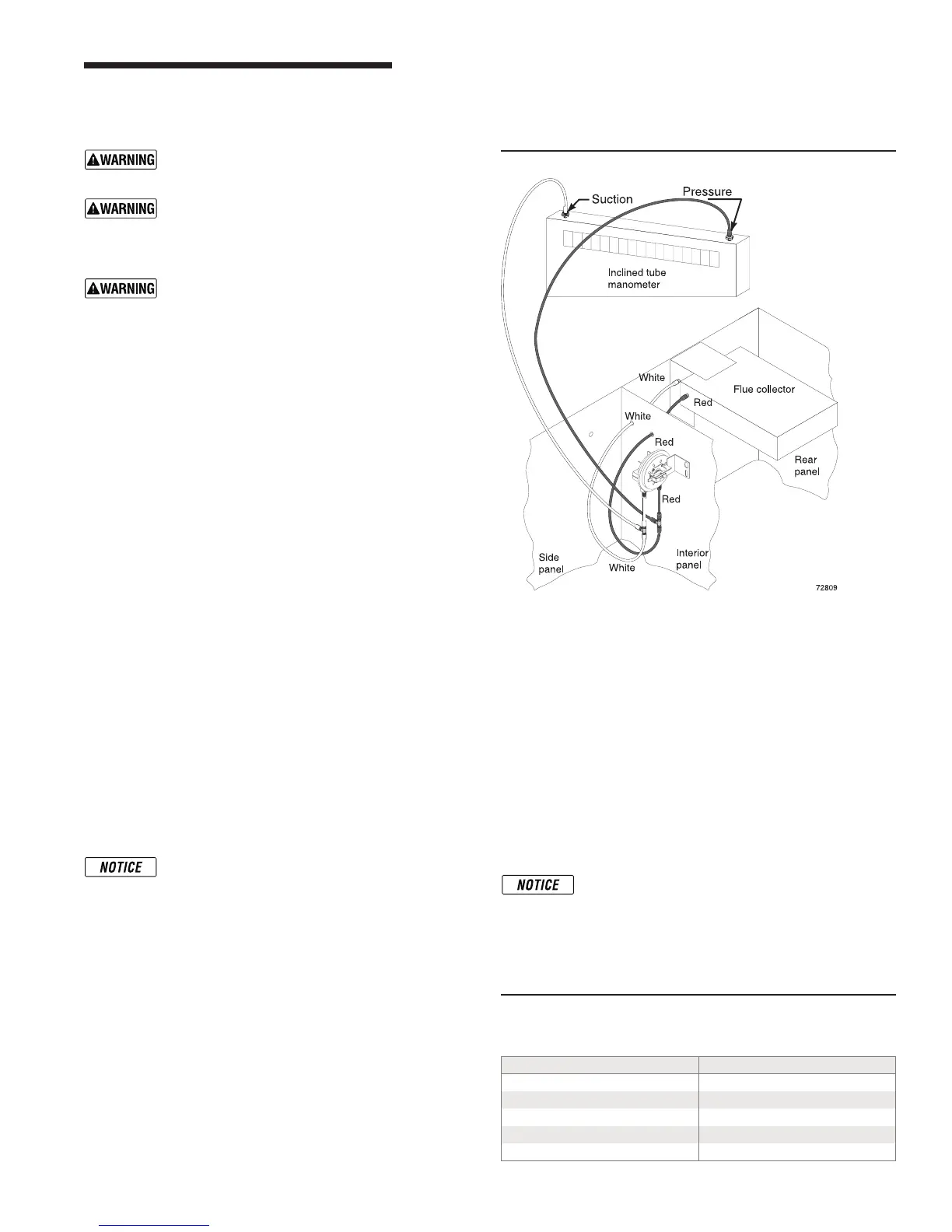

How to check pressure switch setting (if specified

in Troubleshooting charts

)

Make sure boiler water temperature is 100 °F or

coolerbeforestartingproceduretoobtainappropri-

ate readings.

1. See Figure 21 and Table 9.

2. Removeboth air pressure switchhoses from air pressure

switch.

3. Install tees and tubing as shown in Figure 21 to inclined

manometer.

4. Turnoffgasvalveandsetthermostattocallforheat.Inducer

will run but burners will not ignite.

5. Checkfor24VACbetweenbothairpressureswitchterminals.

6. Ifmanometerreadingisabovethesetpointoftheswitch(see

Table 9),butthereisnot24VACbetweenairpressureswitch

terminals“C”and“NO”—replaceairpressureswitch.

Troubleshooting air pressure reading

1. Ifmanometerreadingislowerthanthesetpointoftheswitch

(seeTable 9)—checkforpossiblecauses:

• blockageinhoses

• obstructionininducerhousingoutlet

• looseinducerwheelonmotorshaft

• inducermotornotinproperrpm

• inducerbackplatenotsealedproperly

• blockageinblockassembly

• blockageinuepipeortermination

• incorrectpressureswitch

Return to normal operation

When pressure reading is correct and air pressure switch is

operating properly — remove tees and reinstall hoses to air

pressure switch.

The boiler will not operate correctly unless pressure

switch hoses are correctly located. The red hose

connectsfromtherightside(negative)hosebarb

totheuecollector.Thewhitehoseconnectsfrom

theleftside(positive)hosebarboftheswitchtothe

connectorbox(betweenuecollectorandinducer)

as shown in Figure 21.

Table 9 Pressure switch setpoint (for elevations

above 2,000 ft, contact your local supplier for

details.)

Boiler model number Inches W.C.

GWI-047 and GWI-063

1.19

GWI-095

1.08

GWI-127

0.86

GWI-158

0.61

GWI-190

0.76

Figure 21 Checking pressure switch

Loading...

Loading...