9

Part Number 550-142-785/0812

Table 4 Maximum vent length

Max.vent length

(feet)

Total number of 90° elbows

(Notes 1 & 2)

1 2 3 4 5 6

GWI-047 to GWI-158

55 48 41 34 27 20

GWI-190

35 28 21 14 7 --

Notes:

1. Do not include termination fitting when counting total number of elbows.

2. One (1) 90° elbow is equivalent to two (2) 45° elbows.

GWI

Series 2 Gas-Fired Water Boilers – Boiler Manual

Direct exhaust venting

Obtain vent system components

1. ThefollowingspecialgasventsystemscomplywithUL-1738

andULC-S636standardsandarecertiedbyCSAastheonly

systemssuitableforusewithGWIboilers(all3”diameter):

• Heat-Fab,Inc.Saf-TVent

®

• Flex-LInternational,Inc.StaR-34

• Z-Flex

®

,Inc.Z-VentII

• ProTechSystemsFasNSeal™

Useonlytheventstarterofthesamemanufacturer

astheventcomponents.Donotmixcomponents

fromdifferentsystems.Theventsystemcouldfail,

causing flue gas spillage, resulting in severe per-

sonal injury or death.

2. Selectverticalorsidewallventingdependingonjobrequire-

ments.

3. RefertoTable4formaximumventrunlengthsandnumberof

elbows.DonotexceeddatainTable 4.

4. SelectventcomponentsfromseparateGWI Vent Component

Supplement.Allcomponents,includingtheventstarter,must

beofthesameventmanufacturer.Donotmixcomponents.

1. Select a vent pipe manufacturer from separate GWI Vent

Component Supplement and obtain all vent components

needed, based on boiler location and venting method.

2. Youmustusetheventstarter(seebelow)madebytheventpipe

manufacturer.SeeGWI Vent Component Supplementfor

partnumberofeachcomponent,listedbyventmanufacturer.

Useonlytheventstarterofthesamemanufacturer

astheventcomponents.Donotmixcomponents

fromdifferentsystems.Theventsystemcouldfail,

causing flue gas spillage, resulting in severe per-

sonal injury or death.

3. Follow all applicable national, state, local or provincial codes

whenventingtheGWIboiler.

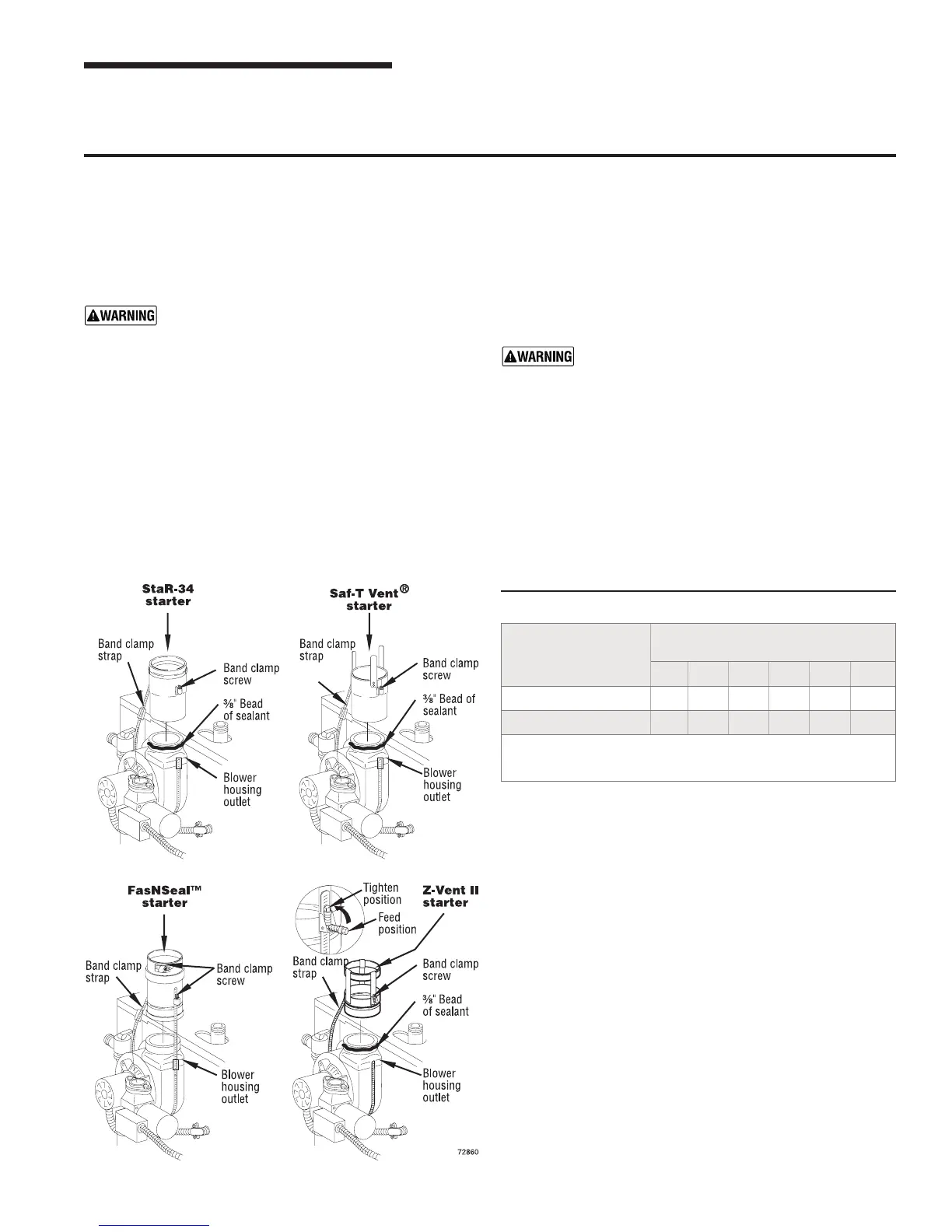

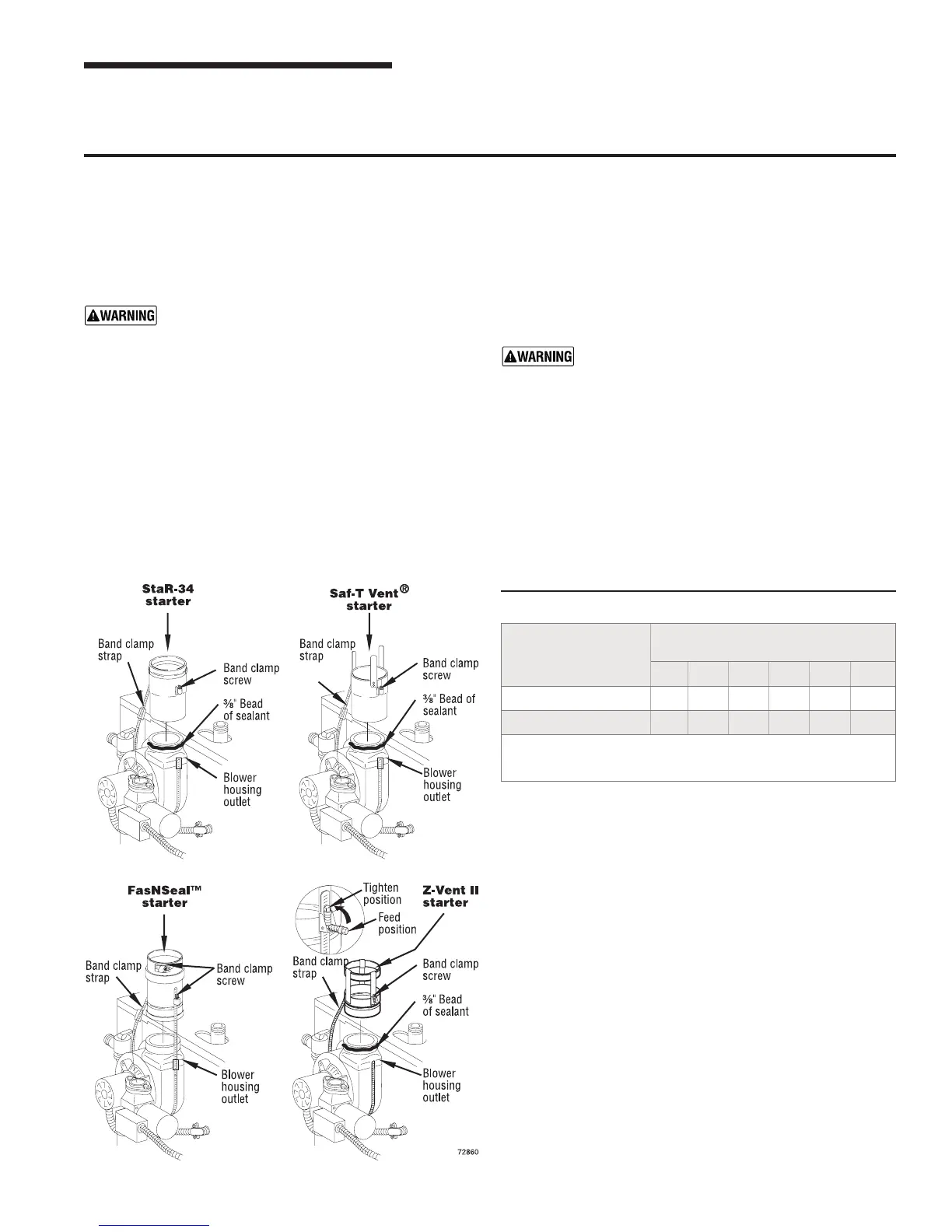

4. Connectventstartertoblowerhousingoutletasshownbelow.

a. Donotmixcomponentsfromdifferentventmanufacturers.

b. Maintainminimum2”clearancefromcombustiblematerials

to vent pipe.

c. Seal with sealant specied byventpipe manufacturer,

using

3

/

8

”bead(notrequiredforFasNSeal™).

d. Tighten strap at band clamp screw until strap is snug

around blower housing.

3 Vent installation continued

Loading...

Loading...