Installation and operating instructions Wilo-Control SC-L 41

OPERATION AND FUNCTION English

NOTE

In case of level measurement using a level

sensor, forced switch-on or switch-off only

takes place if dry-running protection and the

high water alarm are additionally realised with a

oatswitch!

6.2. Menu control and structure

6.2.1. Control

Fig. 6: Operation

Themenuiscontrolledviatheoperatingknob:

• Turn:Selectionandsetvalues

• Press:Changemenulevelorconrmvalue

6.2.2. Set-up

Themenuisdividedintotwoareas:

• Easy menu

For quick commissioning using the factory set-

tings, only the operating mode and the activation

and deactivation values need to be set here.

• Expert menu

For display and setting of all parameters.

Open menu

1. Press operating knob for 3 seconds.

2. Menu item 1.0.0.0 appears.

3. Turnoperatingknobtoleft:Easymenu

Turnoperatingknobtoright:Expertmenu

6.3. Initial commissioning

NOTE

Observe the installation and operating in-

structionsforproductsprovidedon-site(oat

switches, level sensors, connected consumers)

as well as the system documentation!

The following points must be checked before the

initialstart-up:

• Check the installation.

• All terminals must be retightened.

• Motor protection correctly set.

• The separate HAND-0-AUTO switch for each

pump must be set to “AUTO (A)”. The factory

setting for these is “0 (OFF)”!

Switching on

1. Turn main switch to ON position.

2. The display lights up and outputs the latest

information. The display appearance changes

dependingonthesignaltransmitterconnected:

3. The “Standby” symbol appears and the switch-

gear is ready for operation. You can now set the

individual operating parameters.

NOTE

IftheredfaultLEDlightsuporashesimme-

diately after activation, observe the error code

information on the display!

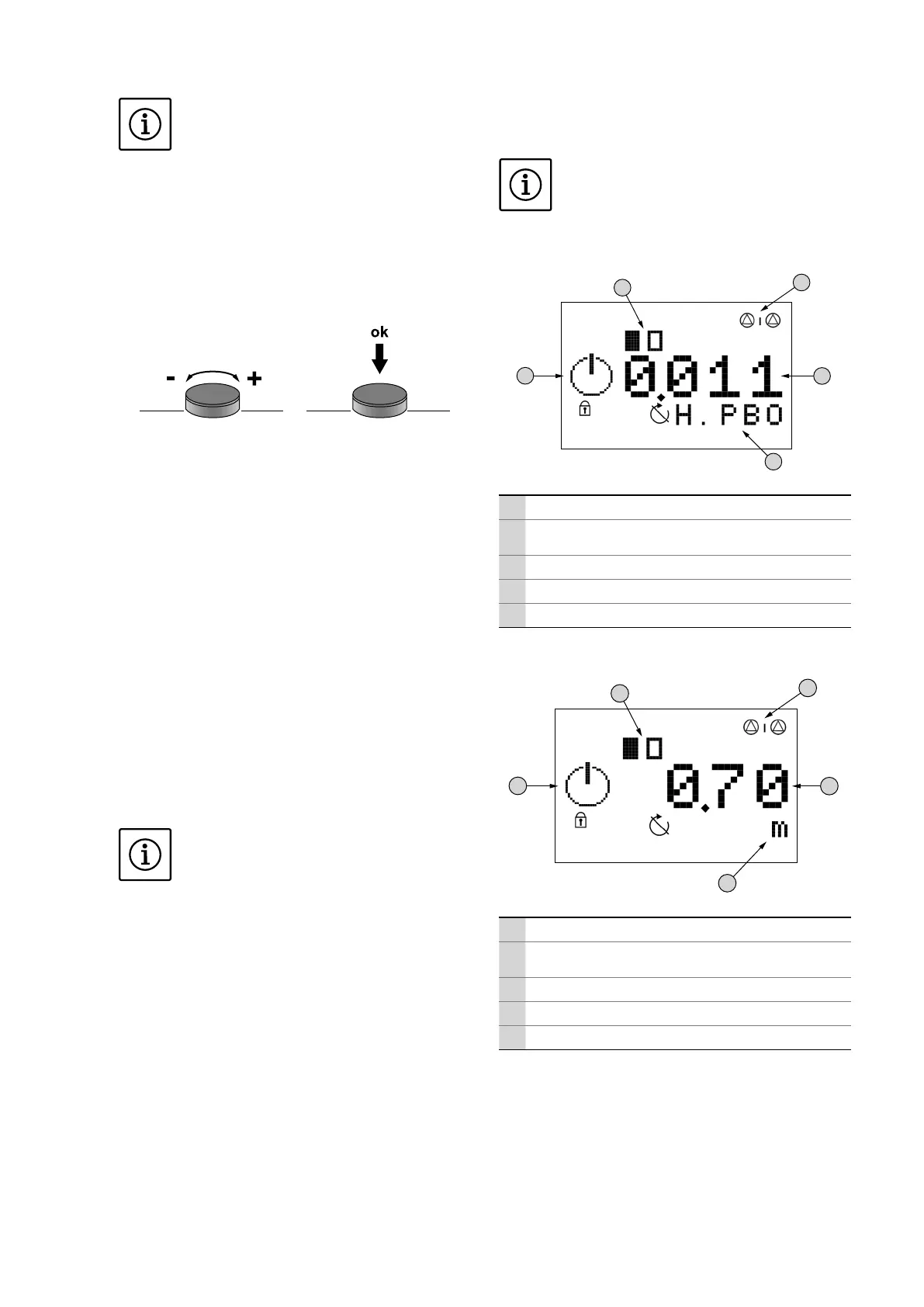

Fig. 7: Appearance of display with oat switch

1

2

3

4

5

1 Control with standby pump

2

Currentpumpstatus:Numberofregisteredpumps/

pump on/pump off

3 Switchingstateoftheindividualoatswitches

4 Float switch designation

5 Area for the display of graphical symbols

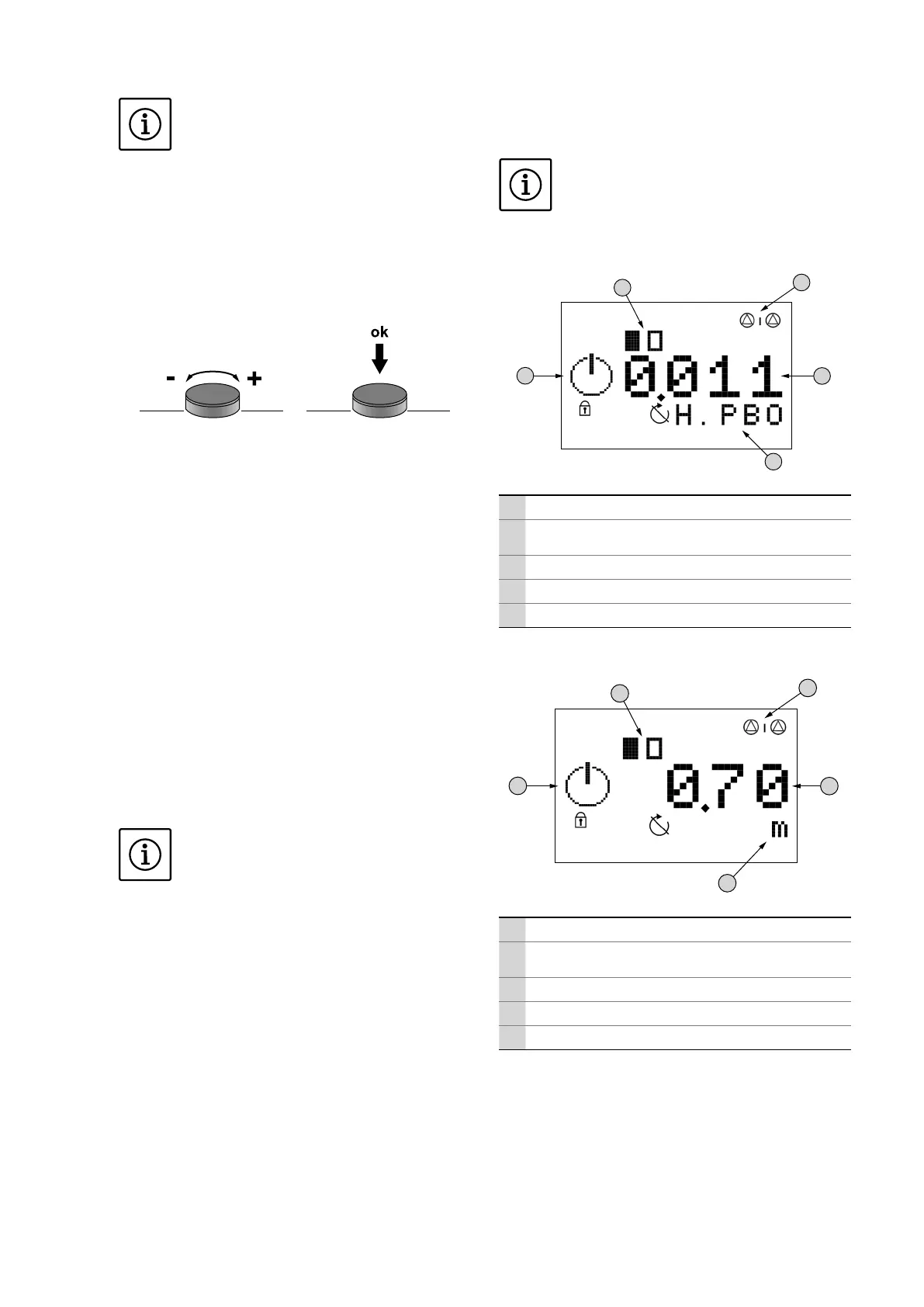

Fig. 8: Appearance of display with level sensor

1

2

3

4

5

1 Control with standby pump

2

Currentpumpstatus:Numberofregisteredpumps/

pump on/pump off

3 Currentlllevel

4 Unit of value currently displayed

5 Area for the display of graphical symbols

6.4. Setting the operating parameters

Themenuisdividedintosevenareas:

1. Control parameters (operating mode, start/stop

delays)

2. Communicationparameters(eldbus)

3. Pump activation (activation and deactivation of

the connected pumps)

Loading...

Loading...