en

52 Installation and operating instructions • Wilo-Control SC2.0-Booster • Ed.01/2023-09

11.1 Fault indication

When a fault occurs, the LCD display lights up permanently, the collective fault signal is ac-

tivated and the fault is shown on the LCD display (error code number).

A faulty pump is indicated on the main screen by a flashing status symbol for the corre-

sponding pump.

• Acknowledge the fault in the menu: Interaction/Communication→Alarms→Acknow-

ledge.

11.2 Fault memory

The control device stores the last 13 errors in the fault memory. The fault memory works

according to the first in/first out principle. The frequency of error messages is displayed.

The overview of the currently existing alarms can be displayed.

• Call up the fault memory via the menus:

– Interaction/Communication→Alarms→Current alarms

– Interaction/Communication→Alarms→Alarm history

– Interaction/Communication→Alarms→Alarm frequency

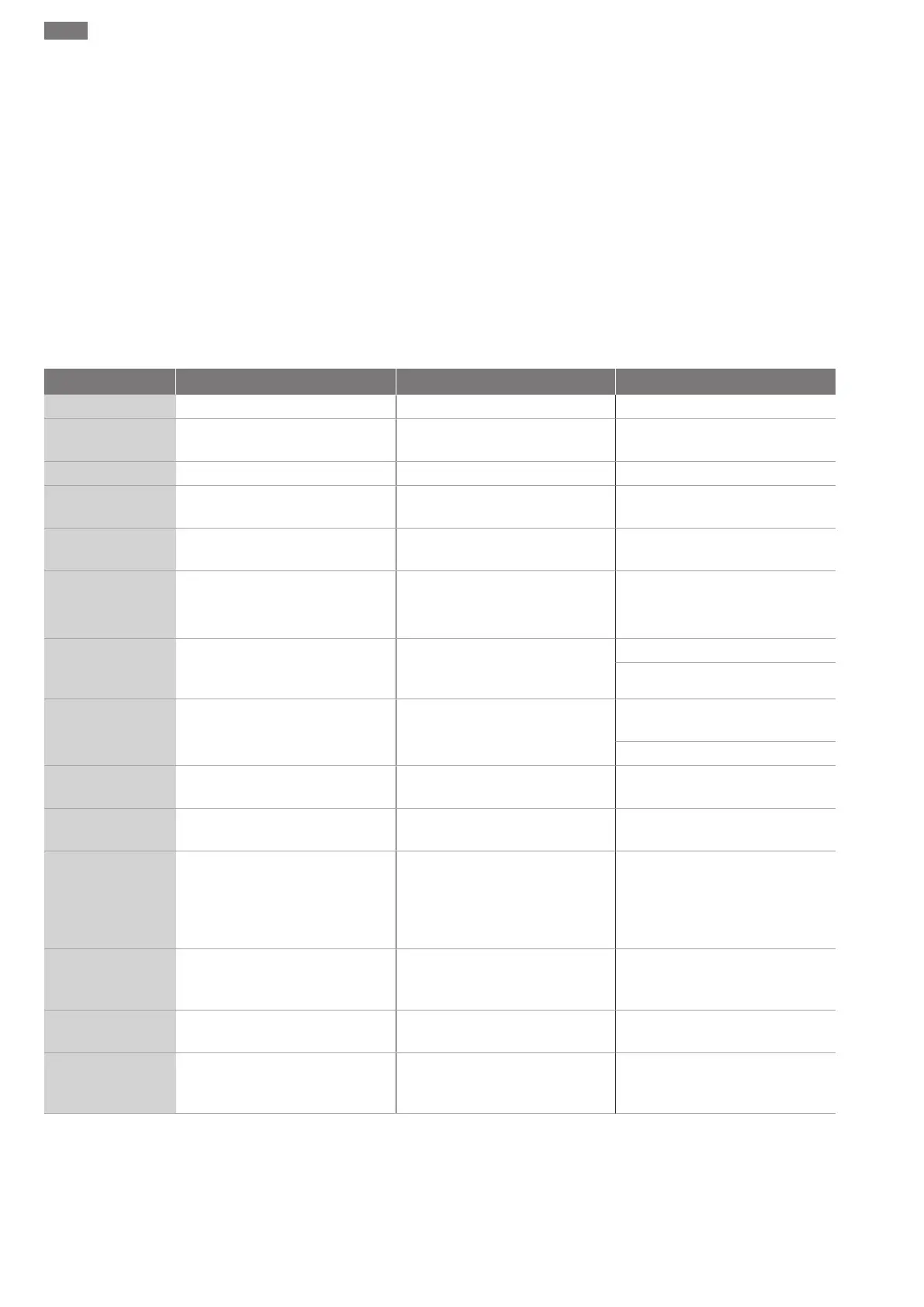

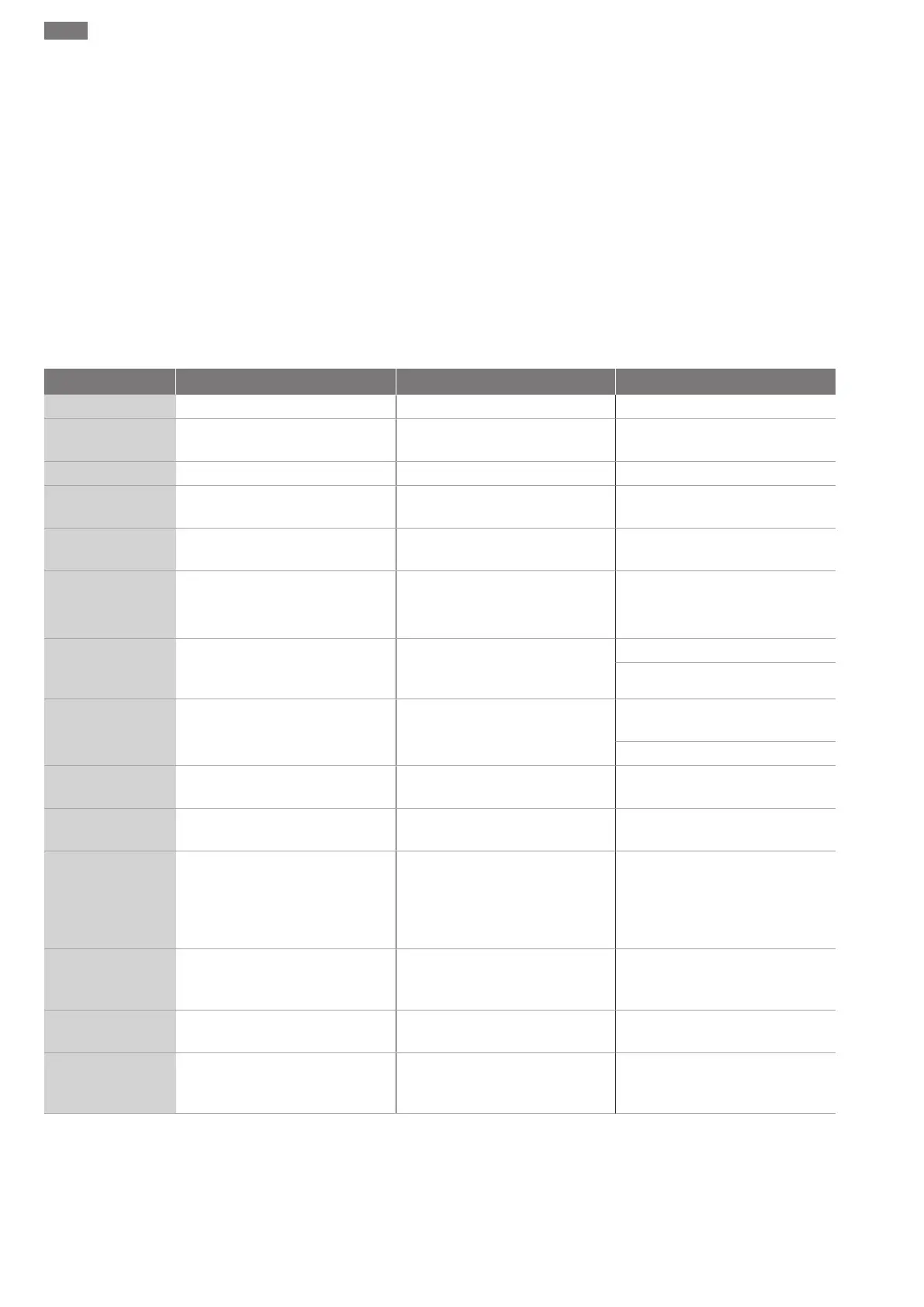

11.3 Error codes

Code Fault Cause Remedy

E040 Sensor outlet pressure disturbed Pressure sensor defective Replace sensor.

No electrical connection to the

sensor

Make the electrical connection.

E040.2 Supply pressure sensor faulty Pressure sensor defective Replace sensor.

No electrical connection to the

sensor

Make the electrical connection.

E043 External setpoint faulty No electrical connection to the re-

mote station

Make the electrical connection.

E054 Connection partner lost Fault in the CAN connection

between control device and pumps

Check cable connection.

Check activation of the terminating

resistors.

E060 * Max. output pressure Output pressure of the system has

risen above the set limit value (e.g.

due to a controller fault).

Check controller function.

Check installation.

E061 * Min. output pressure Output pressure of the system has

dropped below the set limit value

(e.g. due to a burst pipe).

Check whether the default value

corresponds to local conditions.

Check pipe and repair if necessary.

E062 Low water Protection against low water level

triggered.

Check inlet/break tank. Pumps re-

start automatically.

E065 Stagnation Not enough water draw-off in the

system

Increase water intake to improve

hygienic conditions.

E080.1 – E080.4 Pumps 1…4 Alarm Winding excessive temperature

(WSK/PTC)

Clean the cooling fins. Motors are

designed for an ambient temper-

ature of +40°C (see also installation

and operating instructions of the

pump).

Motor protection triggered (over-

current or short-circuit in the supply

line).

Check pump and supply line (see in-

stallation and operating instructions

of the pump).

Fault message of the pump via NWB

(only for SCe)

Check pump (see installation and

operating instructions of the pump).

Fault in the CAN connection

between control device and pump

(only for SCe)

Check cable connection.

Legend:

* Fault must be reset manually.

If there is a “W” in front of the error number, it is a warning.

Loading...

Loading...