10

OPM-171/B

your application’s needs. Consult experts in this field for

assistance in designing this part of the system.

DANGER

Only use ASME pressure vessels. Do not use modified or

damaged pressure vessels because it can result in injury,

death and equipment damage.

An appropriately sized buffer tank is recommended for this

application. This will prevent the compressor from loading

and unloading rapidly extending the life of the equipment.

For most spray foam applications, a 30 gallon buffer tank is

sufficient. Consult your tank supplier for help calculating the

optimal buffer tank for your load profile.

All tanks, lines and valves must be installed in accordance

with the best safety practices with proper pressure relief,

vent and water drain valves.

DANGER

Failure to properly install pressure relief valves can result in

injury, death and equipment damage.

Rotating your air-intake on the compressor towards the

fresh air source can reduce your operating temperature.

You can plumb your air intake outside the enclosure as long

as your pipe is larger than the air intake on the compressor.

CONNECTING TO COMPRESSOR

Locate the 3/4” NPT on the air cooler (reference following

image) and attach your air hose.

ELECTRICAL CONNECTIONS

NOTICE: CLASS 1 WIRING METHODS ARE TO BE USED FOR

ALL FIELD WIRING CONNECTIONS TO TERMINALS OF A

CLASS 2 CIRCUIT

NOTE: The symbol always indicates ground where

shown. All wiring must be completed in accordance with

the National Electric Code as well as any state and local

codes.

You must pay particular attention to wire size requirement

for the amperage of service you are dealing with. The table

below provides you guidance on wire sizing based on

both wire type and amperage. Wire amperages have been

derated for 40° C ambient temperatures operation.

3/4” NPT

GENERATOR CIRCUIT BREAKER

This unit DOES NOT come with a circuit breaker. The circuit

breaker will provide overload protection for the generator.

The following table gives you the recommended circuit

breaker size specifications. See actual breaker for wire

capabilities and torque specifications and restrictions.

Watts Voltage Phase CB AMP

40,000 120/240 1 175-200

40,000 120/208 3 150-175

40,000 120/240 3 125-50

40,000 277/480 3 60-75

The wire must be properly sized between the generator

and the load. Use the table 310-16 of the National Electrical

Code ANSI/NFPA 70. to properly size the wire to meet or

exceed the amperage rating of the circuit breaker installed.

Lug size 10mm

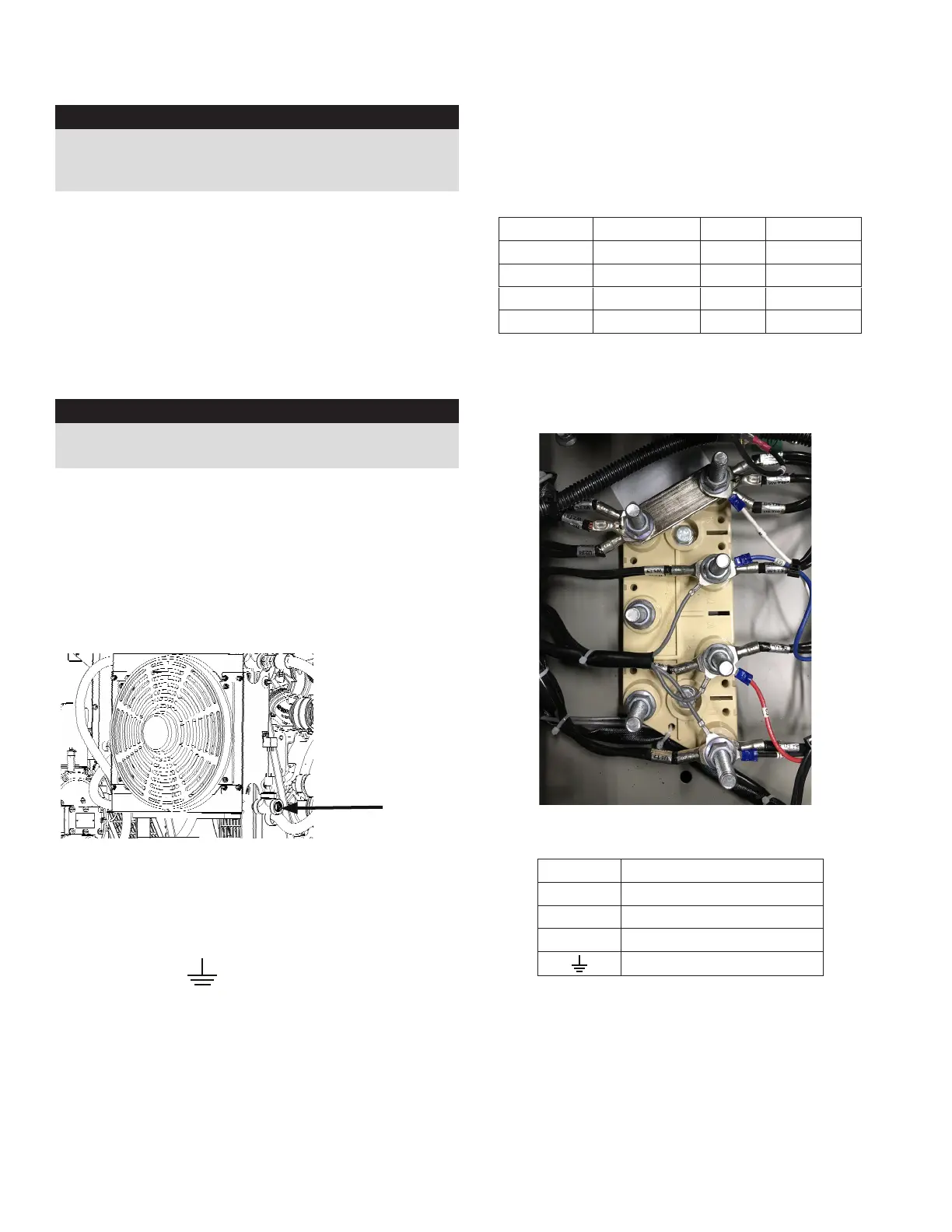

CUSTOMER CONNECTIONS

U Line 1

V Line 2

W Line 3

N Neutral

Ground

The DSE 7310 controller uses current transformers (CT) to

monitor the amount of load on each leg of the generator. If

the wires are routed through the CT the wrong direction it

will result in a negative current readings on the controllers.

This can be corrected by swapping the wires on the CT

terminals in the generator end. Zip tie the wires to the CT

walls after installation in order to prevent wire movement.

N

W

V

U

Loading...

Loading...