19 OPM-171/B

NOTE: The Rotorcomp oil level can only be checked at the

oil filler opening. The screw cap has a safety hole on the

side, oil or air escapes if there is any residual pressure in the

tank.

NOTE: The CAS R3 should be filled until the oil covers no

more than 3/4 of the sight glass. Wait until the compressor

has been off for several minutes to allow the oil in the

system to drain back into the case. Overfilling to the neck

will cause the system to burp oil.

1. Switch off the compressor and disconnect the battery

to prevent the engine from starting.

2. Wait one minute at standstill.

3. Screw off plug of the filler neck by hand with the oil

level depressurized.

4. Check the oil level. Reference the previous diagram.

5. If necessary, top off oil to the maximum level.

6. Screw on the plug firmly by hand.

7. Switch on the system.

8. Check the plug for any leaks, replace the o-ring if

necessary.

9. Carefully remove escaped, excess oil.

CHANGING THE COMPRESSOR OIL

Refer to the maintenance schedule chart for required oil

change intervals.

WINCO recommends our compressor maintenance kits.

WARNING: PERSONAL INJURY

Rotating, pressurized, and hot components. The oil

change can only be changed at a standstill and with the

compressor system completely discharged.

NOTE: Dispose of the used oil according to applicable

regulations.

1. Switch off the compressor and disconnect the battery

to prevent the engine from starting.

2. Completely release the pressure

in the system.

3. Slowly screw off the screw plug

on the oil filler neck.

4. Unscrew the oil drain screw

(ref. 1) and drain the used

oil into an approved container.

5. Clean the oil drain screw and screw back in.

6. Replace the oil filter if necessary. See Changing Oil

Filter of the Air Compressor section of this manual.

7.3

[en] 02/2014

Installation and operating manual - NK 31

Note

The oil filler neck is positioned so that overfilling

of the screw compressor system is not possible.

Excess oil runs out of the filler neck again.

• Screw on the screw plug 1 firmly by hand.

• Switch on the system.

• Check the oil filler plug for leaks and replace

the O-ring if necessary.

• Carefully remove escaped, excess oil.

7.3 Oil change

Warning

Rotating, pressurized and hot components,

DANGER OF INJURY

The oil change may only be carried out at a

standstill and with the screw compressor system

completely discharged.

7.3.1 Oil change intervals

According to the specifications of the system

manufacturer.

For the reference values for the screw compres-

sor compact module, see chapter 7.8 “Mainte-

nance intervals”.

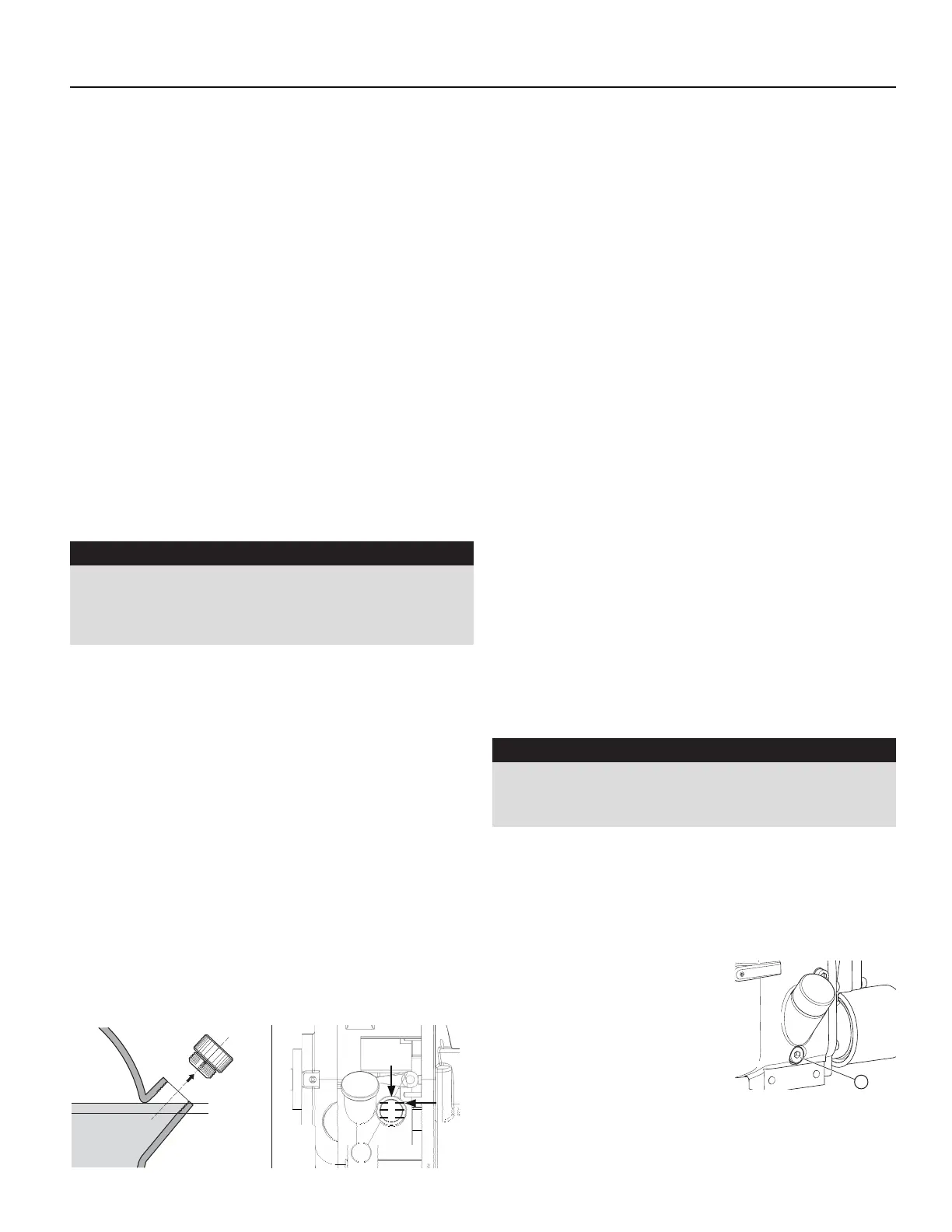

7.3.2 Oil drain points

The system should be at operating temperature

in this case.

Figure 7-2

Note

Dispose of the used oil according to the appli-

cable regulations.

• Switch off the screw compressor and then

secure it against being switched on again by

removing the main switch.

• Completely release the pressure in the screw

compressor system.

• Slowly screw off the screw plug on the oil filler

neck.

• Carefully unscrew the oil drain screw 1 and

catch the used oil in a suitable container.

• Clean the oil drain screw 1 and screw in again.

1

ADJUSTING AIR PRESSURE

A pressure switch controls the air pressure to maintain100

PSI, it will turn off at 125 PSI. Manual adjustments are not

necessary.

If your application requires higher pressure contact Winco

Service. A pressure switch of 120-150 PSI is available and

compatible with this system.

AIR COMPRESSOR MAINTENANCE

All maintenance, assembly, and repair work should be

carried out by an authorized, qualified, specially trained

personnel. These precautions must be followed:

1. Only use suitable tools for maintenance and repair

parts.

2. Only use genuine parts.

3. All maintenance and repair work must only be carried

out with the complete unit shut down and the power

supply switched off. Ensure the machine is secured

against accidental switch-on.

WARNING: PERSONAL INJURY

Before removing plugs, filters, and other pressurized parts,

the compressor must be cut off from all pressure sources

and a pressure relief of the entire system must be carried

out.

4. Never use flammable solvents or carbon tetrachloride

to clean parts.

5. Always ensure the area is clean and free from dirt

when conducting maintenance or repair work. Cover

parts and exposed openings with a clean cloth, paper,

or adhesive tape.

6. Do not conduct any welding or other heat producing

work around the oil system.

7. Ensure no tools, loose parts, or cloths are left on or on

the system.

8. Prior to using the unit, check whether the operating

pressure, temperatures, time settings, and the oil levels

are correct. Also check that the control and switch-off

devices function properly.

CHECKING THE COMPRESSOR OIL

LEVEL

Sight Glass

CAS

1/4

1/2

3/4

Fill To

COMPRESSOR MAINTENANCE

7.2

[en] 02/2014

Installation and operating manual - NK 31ROTORCOMP VERDICHTER

7.2 Oil level

An important factor for the operating safety of the

system is the oil level in the oil reservoir.

The oil level check must be carried out before

commissioning the screw compressor module

and then repeated every 100 operating hours..

The exact oil level check can only be carried out

via the oil filler opening.

Warning

Rotating, pressurized and hot components,

DANGER OF INJURY!

7.2.1 Oil level check via oil filler opening

Warning

– The unit parts, oil and oil filler plug 1 may be

over 80°C/176°F; danger of burns!

Wear personal safety equipment!

– With hot oil, the oil level can be approx. 10 mm

higher than with cold oil shortly after discharg-

ing.

As a result, oil may escape when the oil filler

plug is opened at the maximum oil level. In

this case, close the oil filler plug again imme-

diately and carefully remove the oil which has

escaped.

Figure 7-1

Note

The screw cap of the oil filler neck is provided

with a safety hole on the side from which oil or air

escapes if there is any residual pressure in the

separating tank. Wait briefly in this case.

• Switch off the system and secure it against

unauthorized switch-on.

• Wait for one minute at standstill.

• Screw off the screw plug 1 of the filler neck by

hand with the oil level depressurized.

• Check the oil level.

• If necessary, top up oil of the same oil type and

the same brand up to the maximum level.

MAX

MIN

1

Rotorcomp

Loading...

Loading...