Manual 35018V1 505XT Digital Control System for Steam Turbines

Woodward 183

Event

ID DESCRIPTION MEANING

44 External Trip 14 External Trip #14 contact input was opened

45 External Trip 15 External Trip #15 contact input was opened

46 spare_46 reserved for future use

47 spare_47 reserved for future use

Each individual trip condition is available through the Modbus links to monitor the control status. A

common trip indication is also provided.

Relay indications can be programmed to indicate a 505 Shutdown Condition (energizes for a shutdown

condition) or a Trip Relay (de-energizes for a shutdown/trip), in addition to the dedicated Emergency Trip

Relay output.

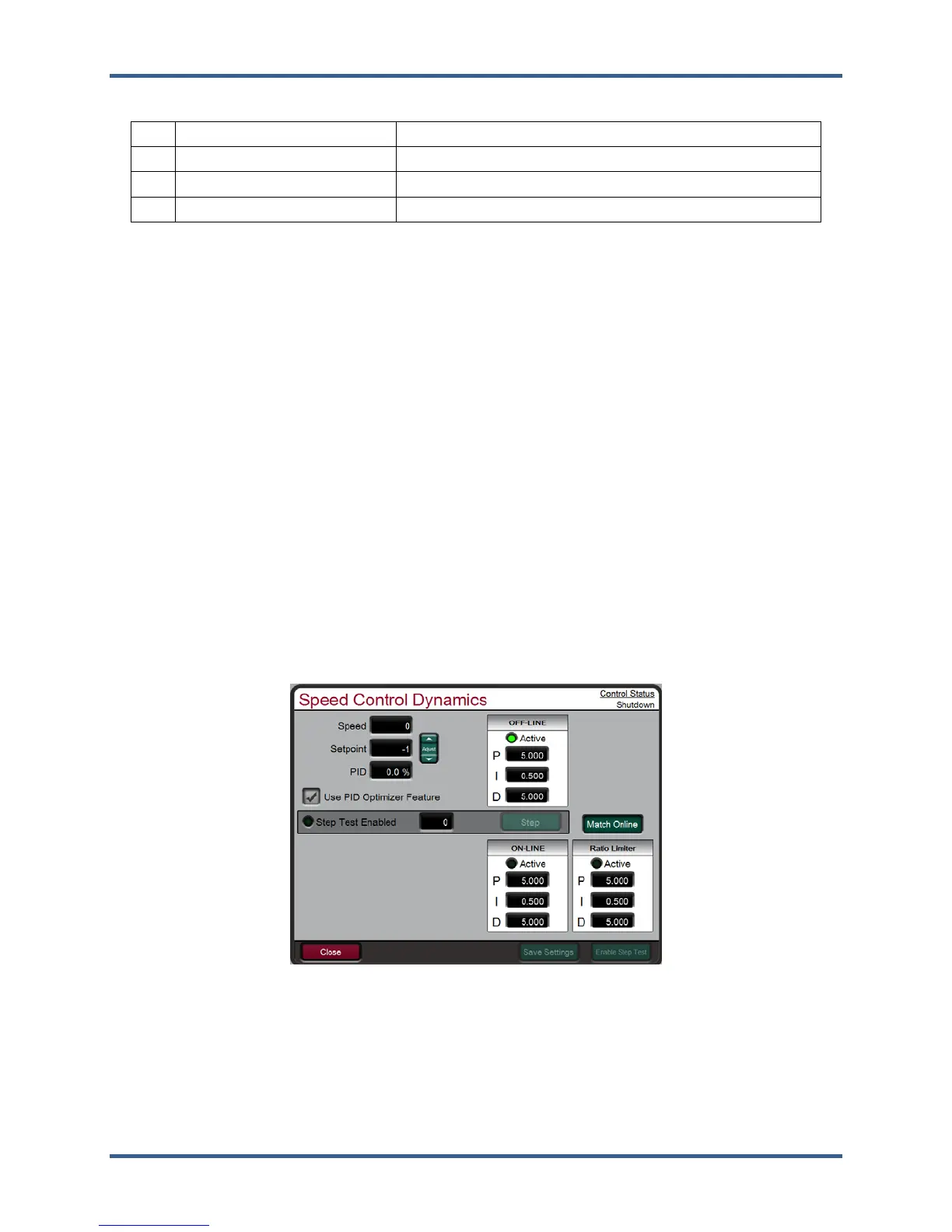

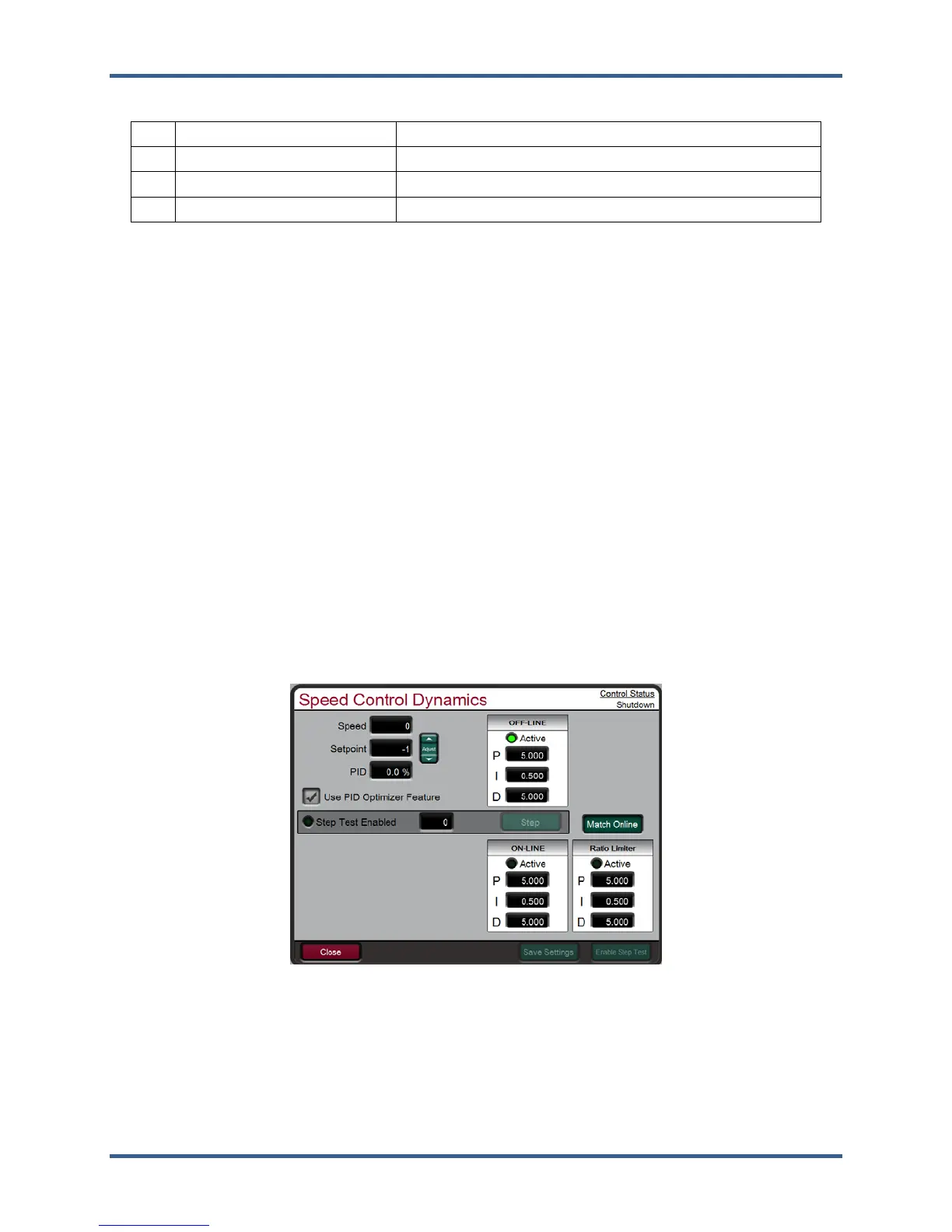

Manual Dynamic Adjustments of Speed, Cascade, Auxiliary, Inlet,

Exhaust and Ext/Adm Controls

This section will cover the basics of the manual tuning of the PID dynamics that need to be performed

initially on the unit. Only the speed control loop is used on every system, the other controls need not be

tuned if they are not configured for use. For the speed and extraction control loops the OPTI tune feature

is available to calculate idea dynamic settings for the overall system. Refer to the OPTI Tune section of

this manual.

Dynamic control values are programmed in the configuration mode and adjusted in the RUN (Operation

or Service) mode. The Proportional and Integral Gain and the Derivative Ratio dynamic adjustments are

available under found under Dynamics pages for each controller (SPEED, CASC, AUX, INLET,

EXHAUST and EXT/ADM). To adjust the gain settings, the In-Focus highlighter must be on the

component value to tune. The In-Focus highlighter is moved using the navigation Cross. The ADJUST UP

and DOWN keys can then be used to adjust the function In-Focus.

Figure 5-32. Speed Dynamics Adjustment Screen

The Speed, Cascade, Auxiliary, Inlet, Exhaust and Ext/Adm controls are PID controllers. The response of

each control loop can be adjusted by selecting the dynamics mode as described above. Proportional

gain, integral gain (stability), and DR (derivative ratio) are the adjustable and interacting parameters used

to match the response of the control loop with the response of the system. They correspond to the P

(proportional), I (integral), and D (derivative) terms, and are displayed by the 505 as follows:

Loading...

Loading...