Manual 35018V1 505XT Digital Control System for Steam Turbines

Woodward 189

Once the routine is complete, the new gains can either be accepted by pressing the ‘Accept’ button within

the Test Menu at the bottom of the screen. Alternatively, the gains can be rejected by pressing the ‘Reset

Test’ button at the bottom of the screen, and the PID gains will change back to the initial values. If

accepted, the current dynamics (offline or online, depending on the current operating mode) will be

updated to the calculated values and the optimizer will reset.

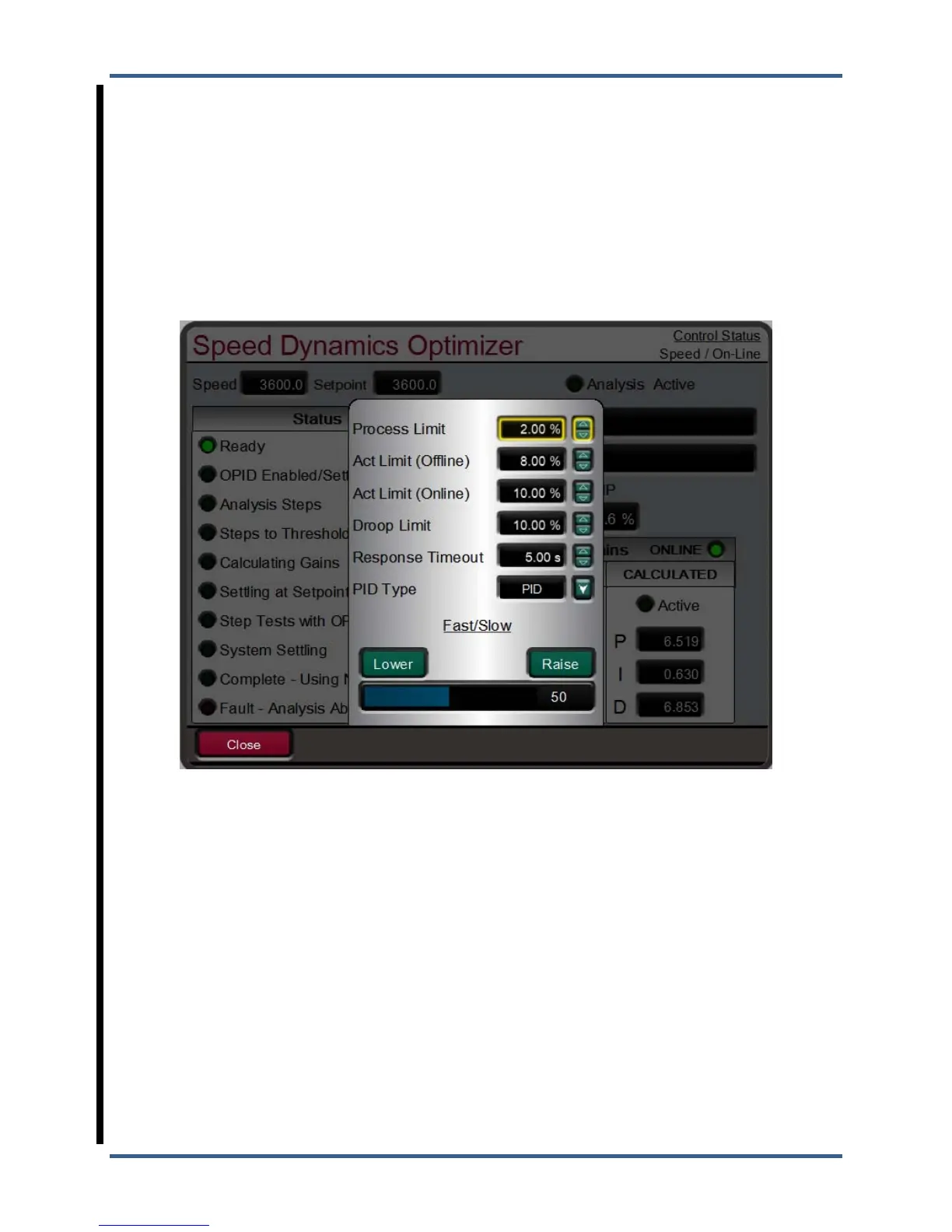

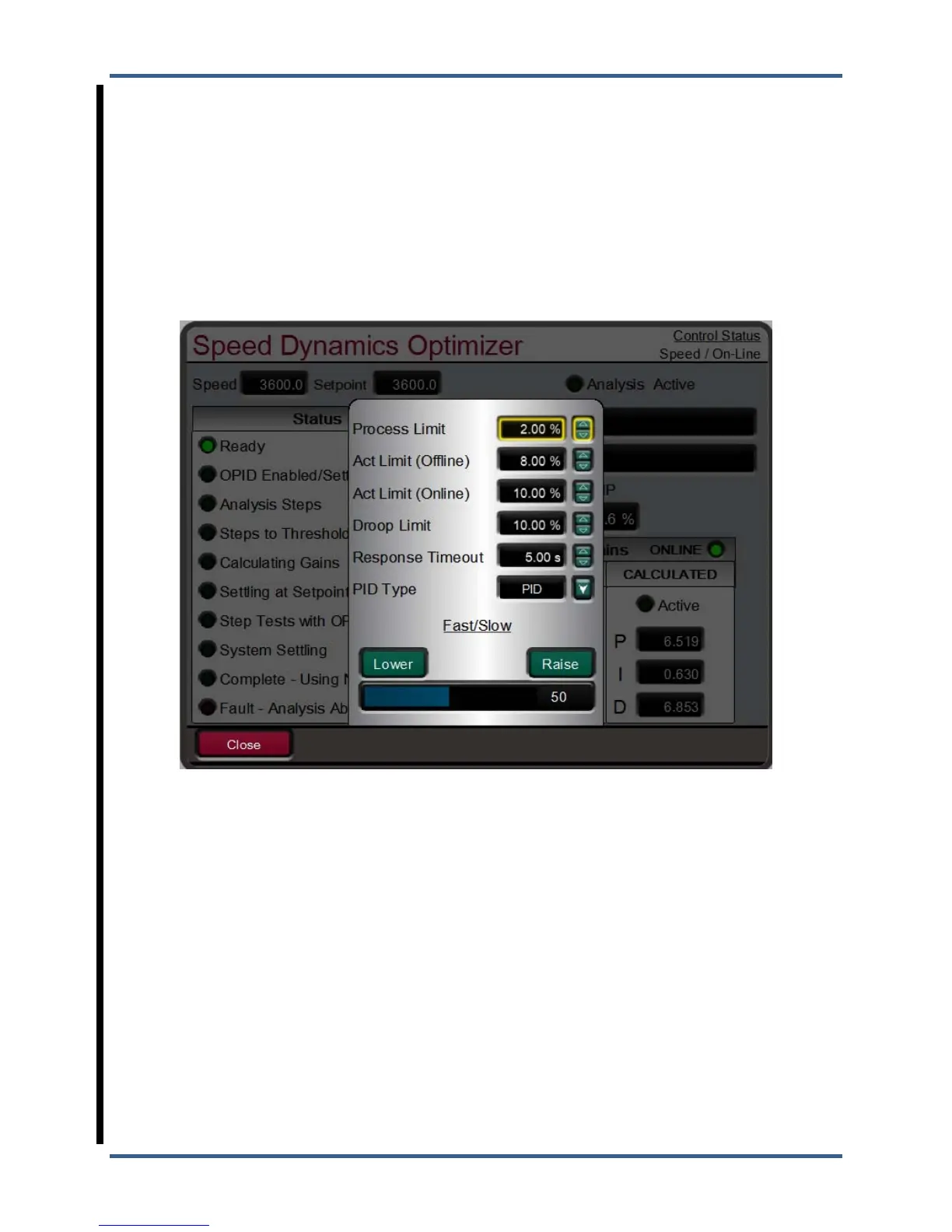

Configuring the Automated PID Optimizer

The configuration parameters are provided in the ‘Configure’ pop-up. The defaults for these values should

allow most systems to successfully optimize. If needed, adjustments can be made to these values to

ensure that the automatic tuning completes successfully. Changing any of these values while the

Optimizer test is running will cause the test to fault and abort.

Figure 5-36. Configuration Parameters ‘Configure’ Pop-up

Process Limit (%) dflt= 2.0 (0.0, 10.0)

This value limits the process signal movement allowed. If movement occurs during automatic tuning that

is more than this value, the Automated PID Optimizer routine will abort and control at the initial SP. This

value should be set based on what the system can tolerate. If it is too low, the automatic tuning process

may fault and abort due to normal process changes. The limit is centered around the current process

value at the time the optimizer is enabled.

For example, if the PID Optimizer is calculating Speed PID gains, and the Process Limit is 2% and

current speed signal is 3600RPM

Upper Process Movement Limit: 3600 + 2% = 3672 RPM

Lower Process Movement Limit: 3600 – 2% = 3528 RPM

If the turbine speed moves outside of the Upper Process Movement Limit or Lower Process Movement

Limit, the PID Optimizer routine will be aborted.

Act Limit (offline) (%) dflt= 8.0 (0.0, 100.0)

This value limits how much the actuator demand will move during the Analysis Mode when the turbine is

using Offline dynamics. The percentage will limit the output +/- from the actuator position when the

optimizer is enabled. The optimizer will not abort if this limit is reached, but an alarm will be annunciated.

Loading...

Loading...