Installation

6720813174 (2014/09) 5

5Installation

5.1 General installation instructions

▶ Connect all pipes without forcing them into place.

▶ Make sure that the connections are tight and carry out a gas and

water tightness test after completing the connection work ( boiler

installation and servicing instructions).

5.2 Making the gas connection

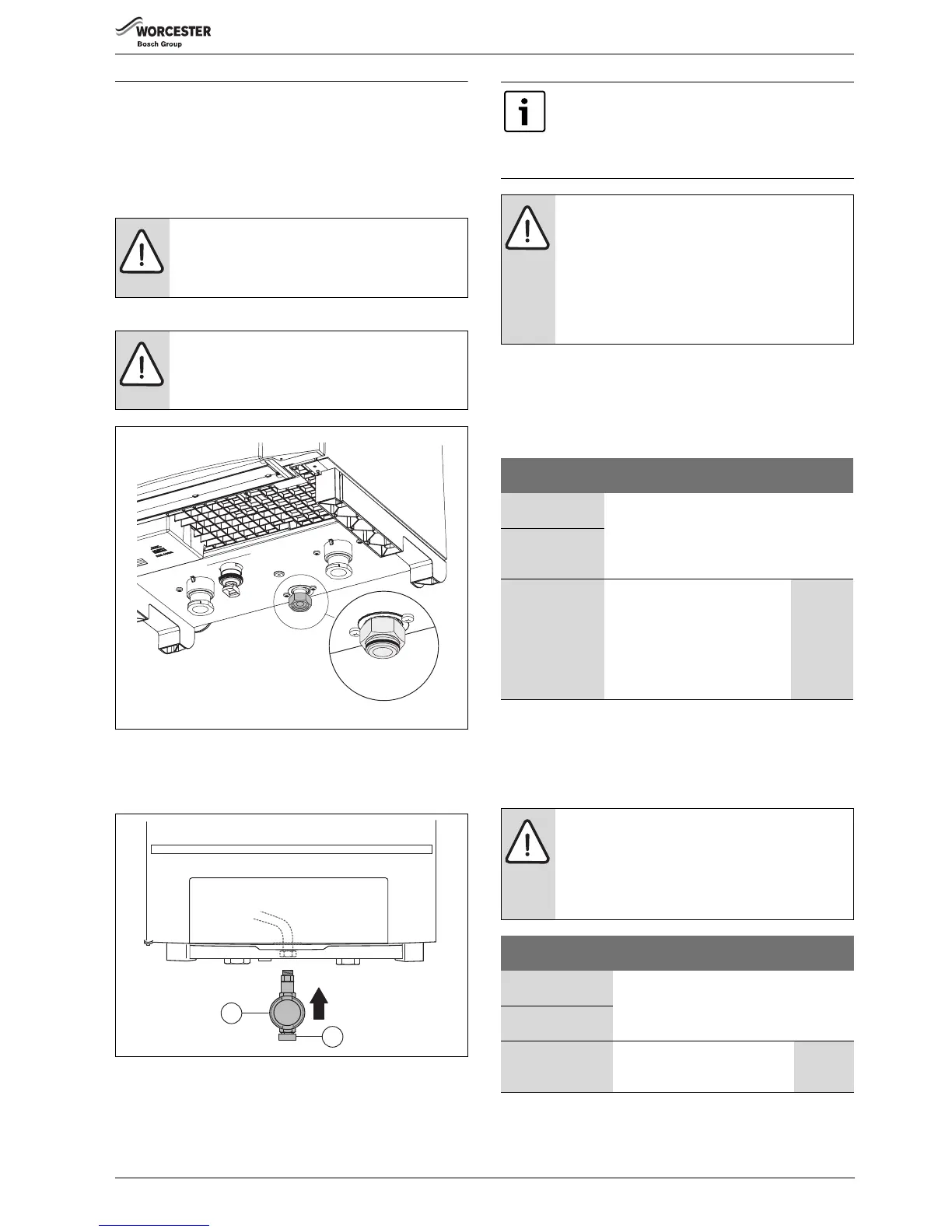

Fig. 3 Rubber seal

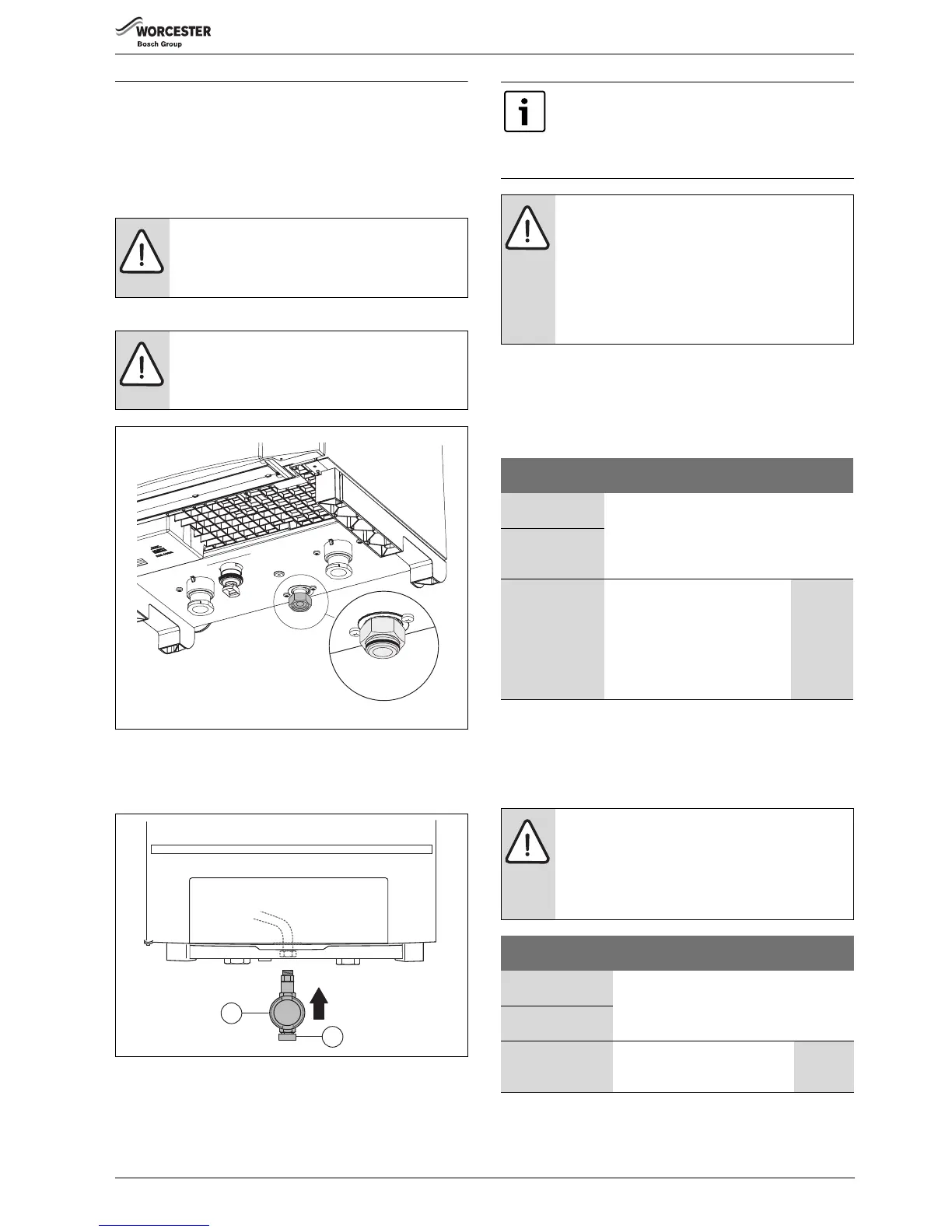

▶ Install the gas valve [1] onto the gas pipe (GAS) in the boiler.

▶ Connect the main gas supply to the gas isolating valve [2] free of

strain.

Fig. 4 Making the gas connection

[1] Gas isolating valve

[2] Gas connection

5.3 Removing the non-return valve (if necessary)

If the system pressure is not sufficient according to table 4, page 7, you

can remove the integrated non-return valve from single-boiler systems.

Selecting the correct pump group

▶ Select the correct pump group using table 4.

DANGER: Danger of fatal accident from explosive

fumes.

▶ Only carry out work on gas pipes and fittings if you

are properly certified (e.g. Gas Safe registered).

DANGER: Danger of fatal accident due to gas escaping.

▶ Make sure that the factory-fitted flat rubber seal is

located in the threaded connection (boiler side)

( fig. 3, detailed picture).

We advise you to integrate a gas filter in the gas line.

▶ Make the gas connection according to the country-

specific standards and regulations.

▶ Carry out gas leak test on gas connection using leak

detection spray

WARNING: Danger of fatal accident from explosive

fumes.

Pipes and screw connections may leak after

commissioning and maintenance activities have been

carried out.

▶ Carry out a leakage test.

▶ Only use approved detection products to locate

leaks.

GB162-

50

GB162-

65

GB162-

80

GB162-

100

Multi-boiler system

(cascade system)

UPER 25-80/UPS 25-80

pump group with pump

Single-boiler

system with

diverter valve

Single-boiler

system without

diverter valve

UPER 25-80/UPS 25-

80 pump group with

pump

1)

UPER

25-80/

UPS 25-80

pump

group with

pump

1) Only remove the non-return valve from the pump group (beneath the pump)

when installing single-boiler systems

2)

2) Do not use a pump group or switch, but select a separate pump using the

installation and servicing instructions with the boiler.

Table 2 Selecting the correct pump group

WARNING: Damage tot the unit in cascade systems or in

single-boiler systems with a switch due to the heating

medium flowing back.

▶ Only remove the non-return valve from the pump

group of a single-boiler system if the residual head

( table 4, page 7) is not sufficient.

GB162-

50

GB162-

65

GB162-

80

GB162-

100

Multi-boiler system

(cascade system)

not allowed

Single-boiler system

with diverter valve

Single-boiler system

without diverter

valve

Check the residual head

not

effective,

use pump

Table 3 Removing the non-return valve

Loading...

Loading...