Installation

6720813174 (2014/09)6

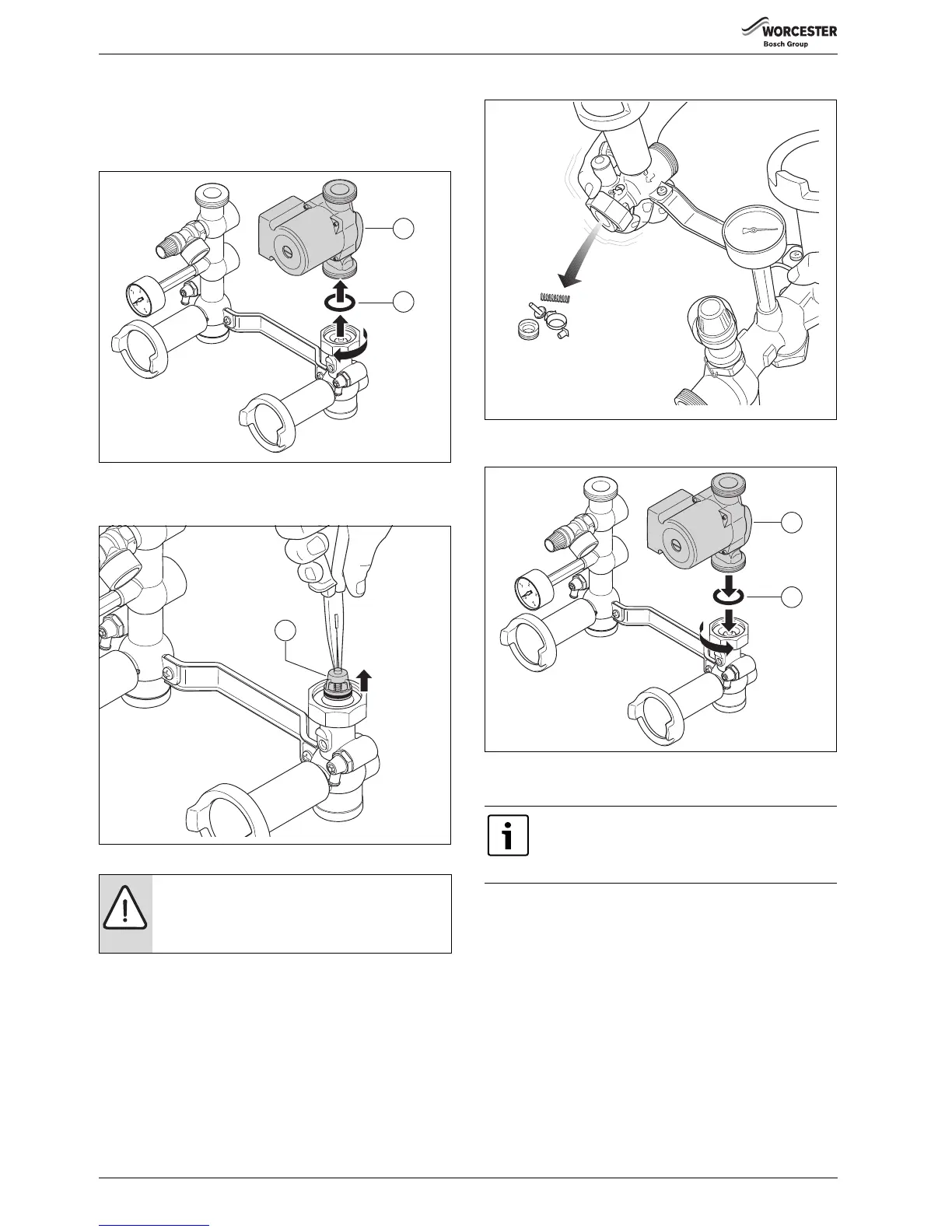

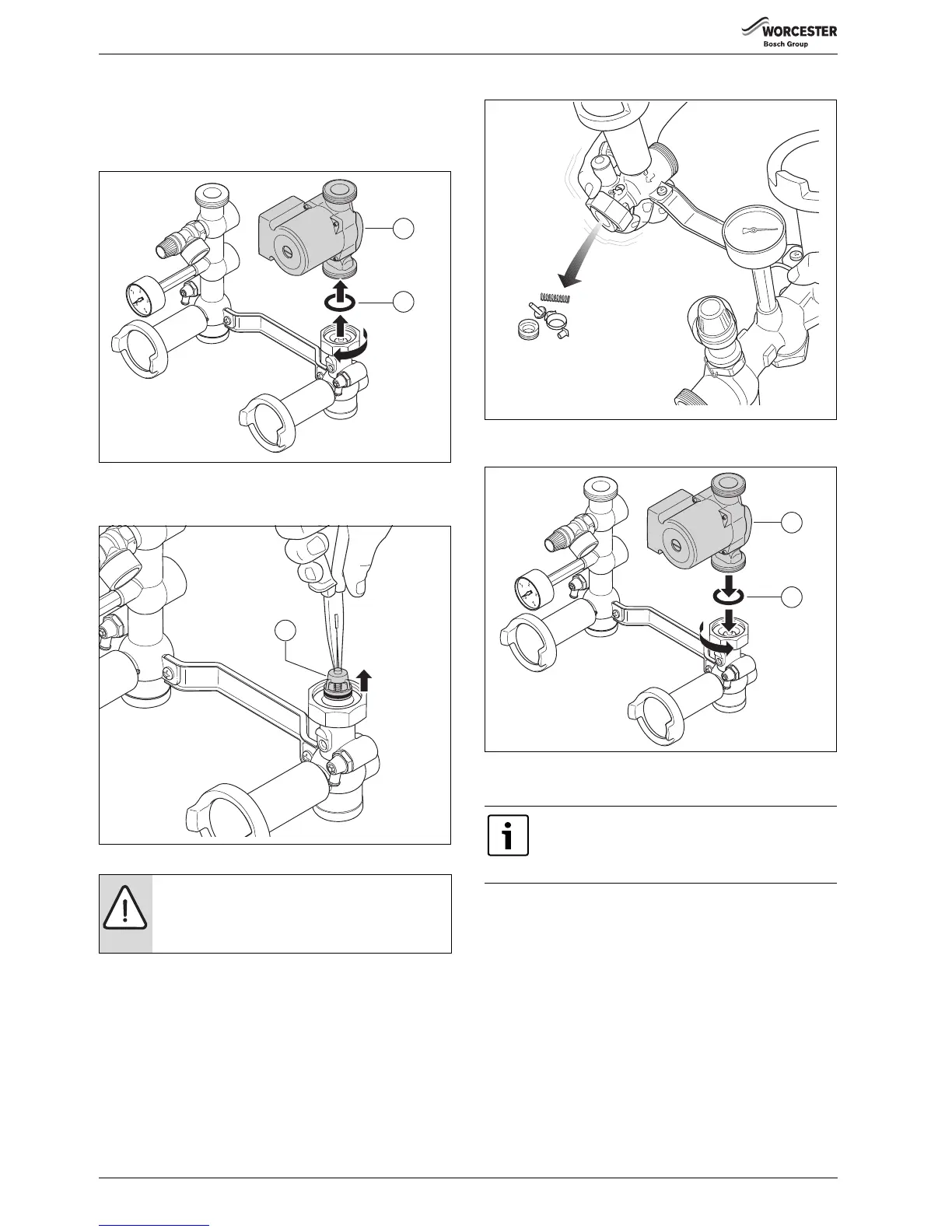

Removing the non-return valve

Remove the non-return valve before installing the heating flow and

return circuits otherwise it cannot be fully removed anymore!

▶ Remove the pump [1].

▶ Remove the flat rubber seal [2].

Fig. 5 Removing the pump

▶ Remove the non-return valve [1]. This will damage the non-return

valve beyond repair.

Fig. 6 Removing the non-return valve

▶ Rotate and shake the pump group.

Fig. 7 Removing the rest of the non-return valve

▶ Then fit back the flat rubber seal [2] and the pump [1].

Fig. 8 Fitting the pump

5.4 Installing the heating flow and return

▶ Install the blue and red isolating valve [2 and 6] with the flat rubber

seals in place on the CHR and CHF (boiler return and flow)

connections.

▶ Connect the flow pipe to the red isolating valve [3] free of strain. If

necessary, use the screw fitting (accessory, [4]).

▶ Connect the return pipe to the blue isolating valve [7] free of strain.

If necessary, use the screw fitting (accessory, [4]).

▶ Calculate the flow and return pipe diameters taking into

consideration the residual head downstream of the pump group with

the minimum required volume flow ( table 4, fig. 24 and fig. 25 on

page 11). The minimum diameters of the flow and return pipes are

1½’’ and Ø 35 mm.

WARNING: Damage to the unit due to reduced flow or

pipes becoming clogged up.

▶ Make sure that no fragments of the non-return valve

stay behind in the pipe.

To prevent pollution in the heating system we advise you

to integrate a dirt filter in the return circuit. When

connecting the heating boiler to an existing heating

system, this dirt filter must be installed.

Loading...

Loading...