Page 38 of 39 WIM-TD-002_C

Trouble shooting Guide

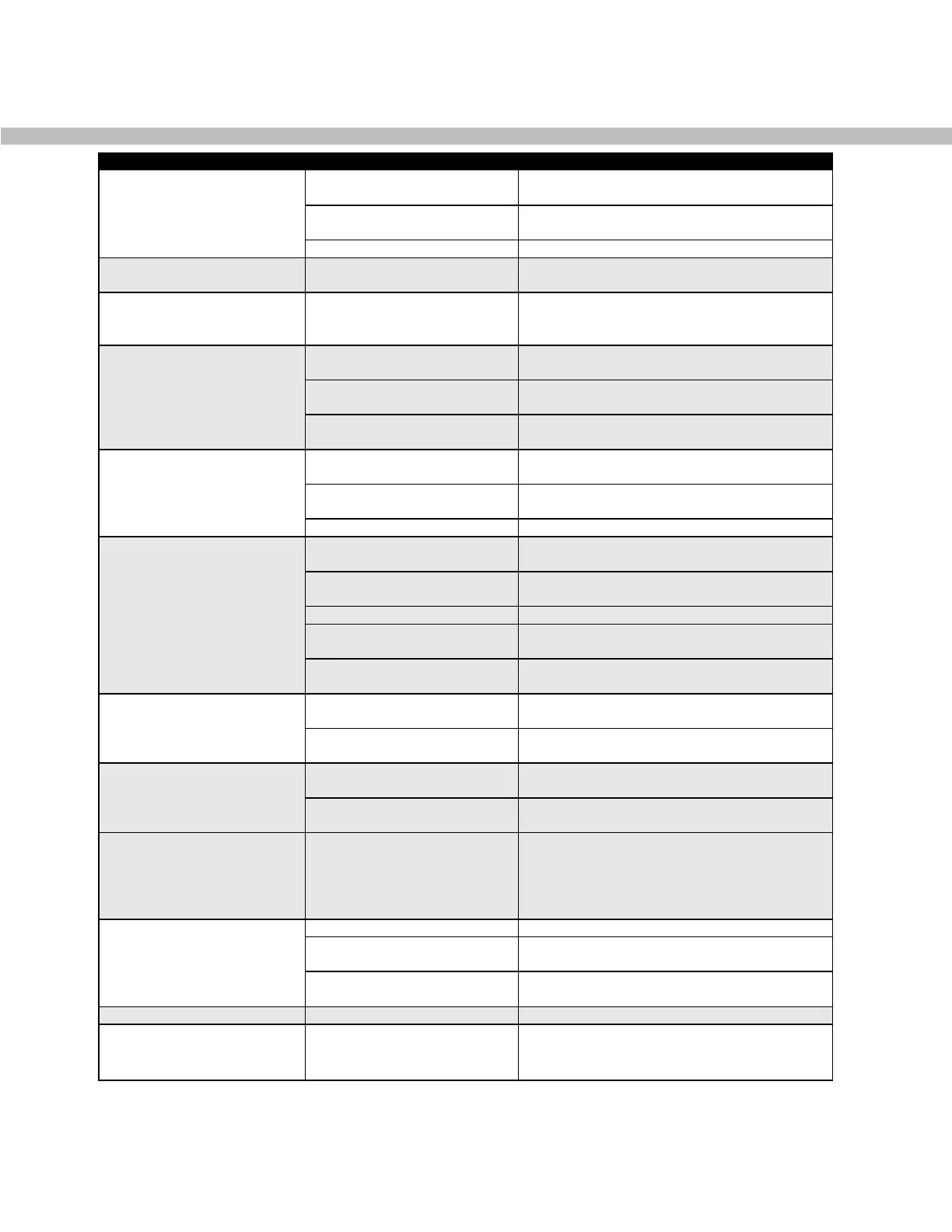

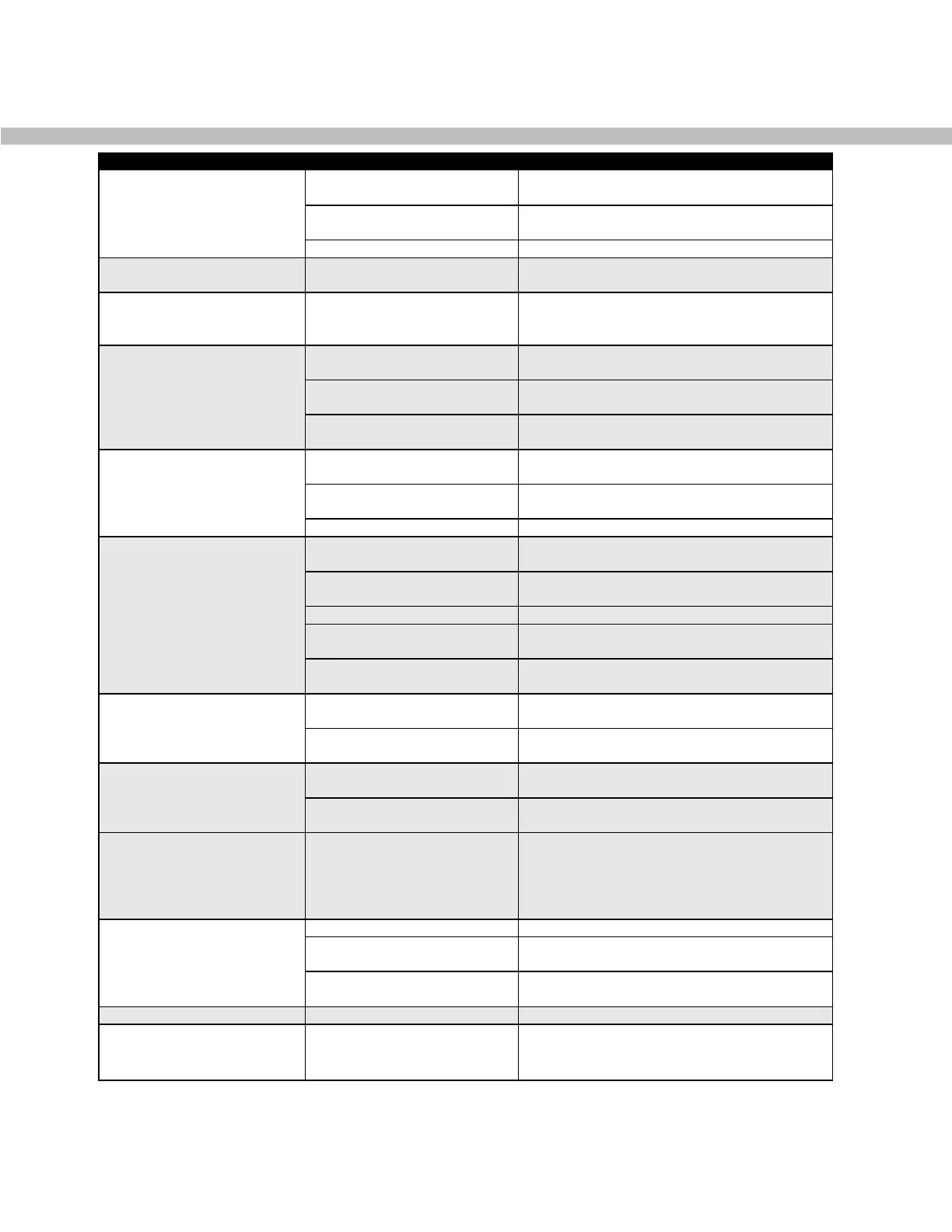

PTO Will Not

Engage/Disengage

Improper engagement torque

Check engagement torque and adjust as

necessary

Worn or damaged friction

discs

Inspect friction discs and replace as needed

Inspect clutch pack and remove debris

Ringing or Knocking Sound

While Disengaged

Grinding/Scraping Sounds

While Engaged or

Disengaged

Inspect main bearings and replace as

needed

Clutch Slips, Burnt Smell,

and/or Smoke from PTO

Improper engagement torque

Check engagement torque and adjust as

necessary

Worn or damaged friction

discs

Inspect friction discs and replace as needed

Sliding sleeve assembly

contacting clutch shaft

Check for axial loading on operating shaft

Inspect endplay and runout on engine

flywheel, replace as needed

Inspect main bearings and replace as

needed

Check alignment, adjust as needed

Split Friction Disc or Broken

Teeth

Inspect drive ring teeth and replace as

needed

Engagement speed is too

high

Check alignment, adjust as needed

No support outboard support

plate

Check if unit requires outboard support,

install if needed

High inertia or shock load

starts

Contact WPT Power Applications

Engineering for support

Improper engagement torque

Check engagement torque and adjust as

necessary

Worn or damaged friction

discs

Inspect friction discs and replace as needed

Frequent Adjustments

Needed to Engagement

Torque

Engagement speed is too

high

Reduce engagement speed to below 1000

r/min

Excessive force on operating

handle

Reduce operating force to spec

Clutch Will Not Fully Seat on

Bell Housing

Flywheel bore depth too

shallow

Measure bore depth, contact WPT Power

Applications Engineering

Bearing Carrier Hot

(Temp 200° F)

Too much or too little grease

Adjust belt tension according to belt

manufactures recommendations

Inspect main bearings and replace as

needed

Run at idle speed until grease outflow stops

Axial Movement in the Clutch

Shaft When Engaging or

Disengaging PTO

Normal operational movement

Loading...

Loading...