ENGINE

WG972-E4, WSM

1-S18

• When removing the radiator cap, wait at least ten minutes after the engine has stopped and cooled down.

Otherwise, hot water may gush out, scalding nearby people.

9Y1211108ENS0013US0

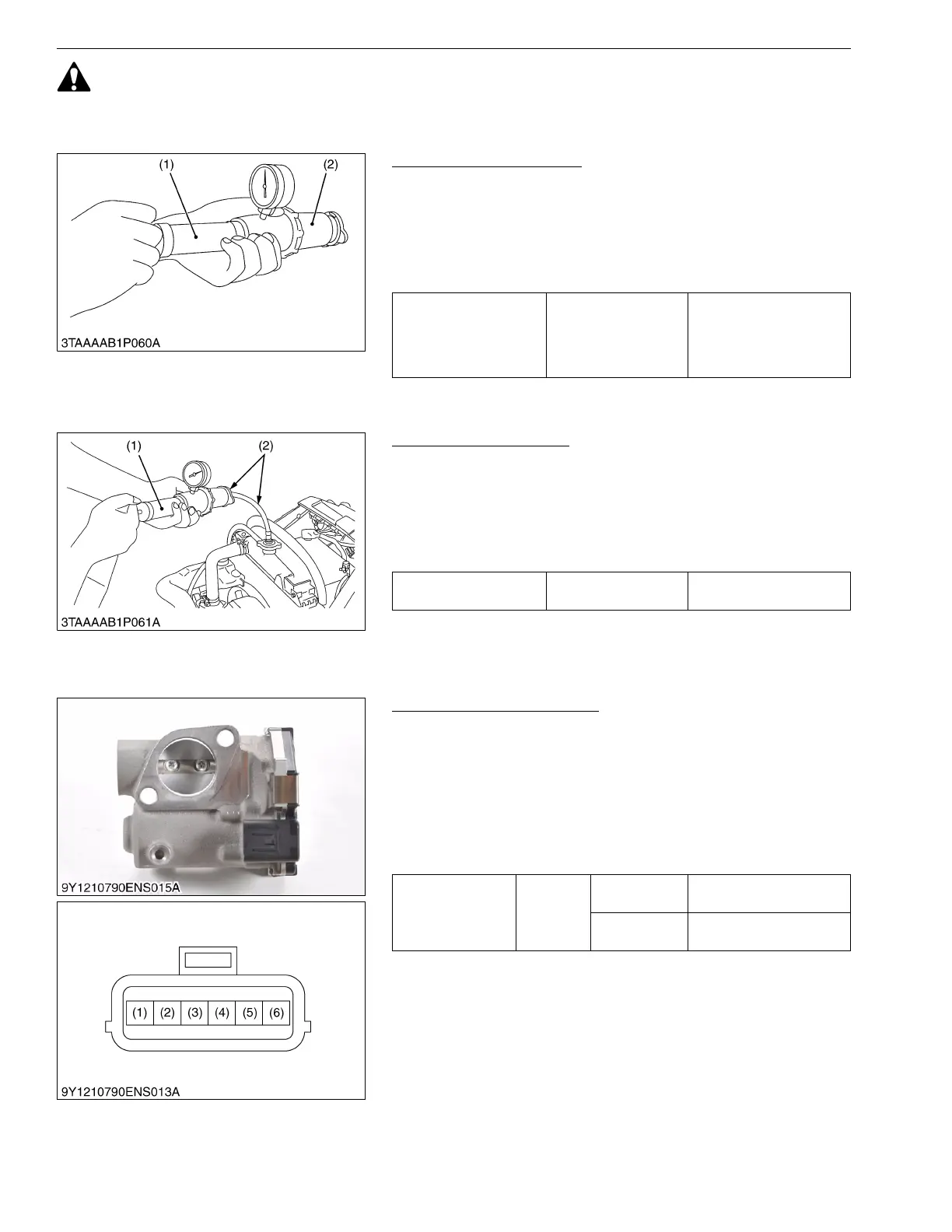

Radiator Cap Air Leakage

1. Set a radiator tester (1) and an adaptor (2) on the radiator cap.

2. Apply the specified pressure (90 kPa, 0.9 kgf/cm

2

, 10 psi), and

measure the time for the pressure to fall to 60 kPa (0.6 kgf/cm

2

,

9 psi).

3. If the measurement is less than the factory specification,

replace the radiator cap.

9Y1211108ENS0014US0

Radiator Water Leakage

1. Pour a specified amount of water into the radiator.

2. Set a radiator tester (1) and an adaptor (2) and raise the water

pressure to the specified pressure.

3. Check the radiator for water leaks.

4. For water leak from the pinhole, repair with the radiator cement.

When water leak is excessive, replace the radiator.

9Y1211108ENS0015US0

(4) Fuel System

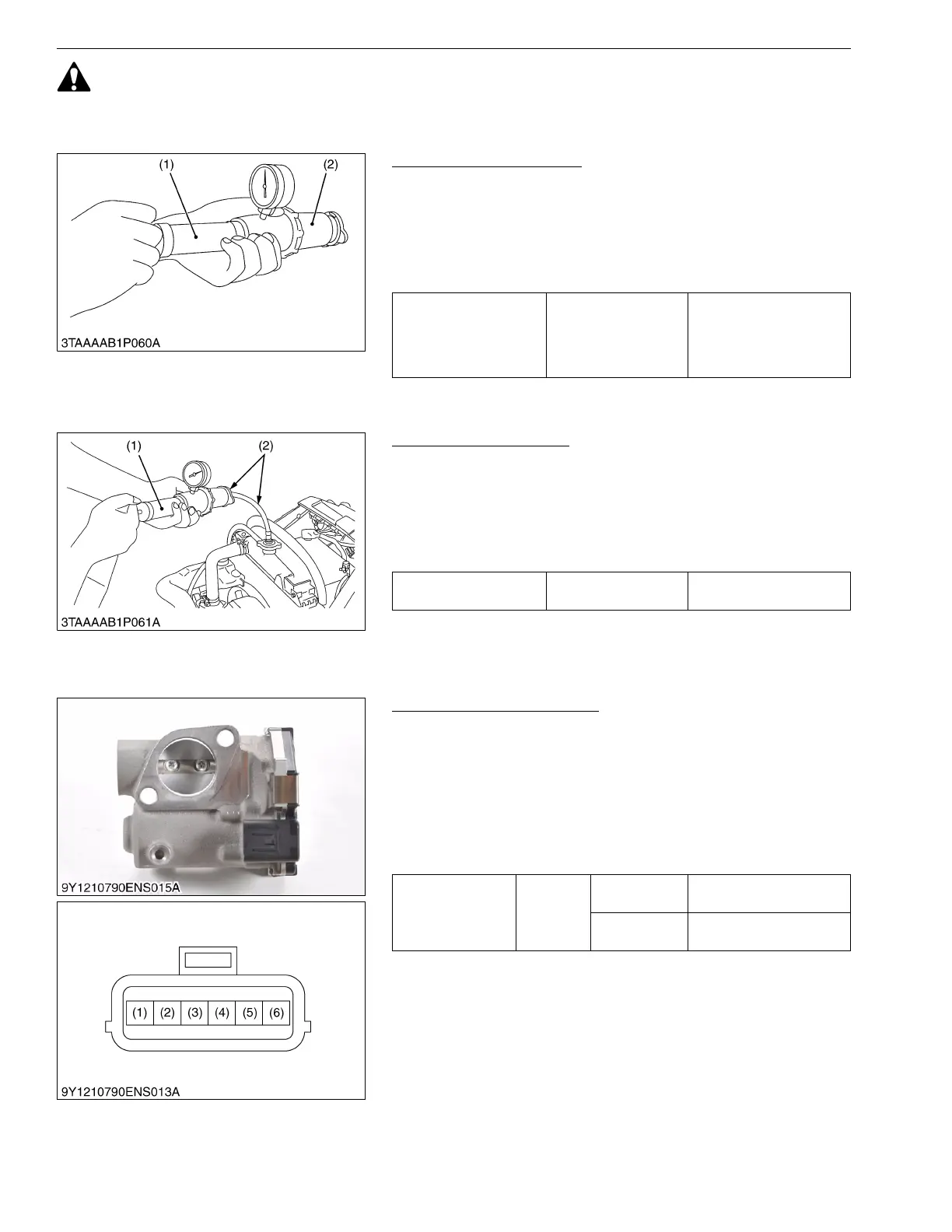

Resistance of Throttle Body

1. Disconnect the connector.

2. Measure the resistance between terminal 1 and terminal 4 with

an ohmmeter.

3. If the resistance is 0 ohm or infinity, replace it.

4. Measure the resistance between terminal 2 and terminal 3 with

an ohmmeter.

5. If the resistance is not with in the factory specifications, replace

it.

9Y1211108ENS0016US0

Pressure falling time Factory specification

More than 10 seconds

for pressure fall from

90 to 60 kPa

from 0.9 to 0.6 kgf/cm

2

from 10 to 9 psi

(1) Radiator Tester (2) Adaptor

Radiator water leakage

test pressure

Factory specification

No leak at specified

pressure

(1) Radiator Tester (2) Adaptor

Resistance

Factory

specifica-

tion

Terminal 1 –

Terminal 2

Continuity

Terminal 3 –

Terminal 4

Continuity

(1) Terminal 1

(2) Terminal 2

(3) Terminal 3

(4) Terminal 4

(5) Terminal 5

(6) Terminal 6

Loading...

Loading...