ENGINE

WG972-E4, WSM

1-S41

(2) Cylinder Head and Valves

Top Clearance

1. Remove the cylinder head.

2. With the piston at TDC, use grease to affix three or four

plastigauges of a diameter 1.5 mm (0.059 in.) × 5.0 to 7.0 mm

(0.20 to 0.27 in.) long to the crown of the piston; keep the

gauges away from the intake valve and combustion chamber

fittings.

3. Take the piston to an intermediate position, install the cylinder

head and tighten the head bolts to the specified torque.

4. Turn the crankshaft so the piston goes through TDC.

5. Remove the cylinder head and measure the thickness of the

plastigauges.

6. If they are out of spec, check the oil clearance of the crank pin

journal and piston pins.

9Y1211108ENS0063US0

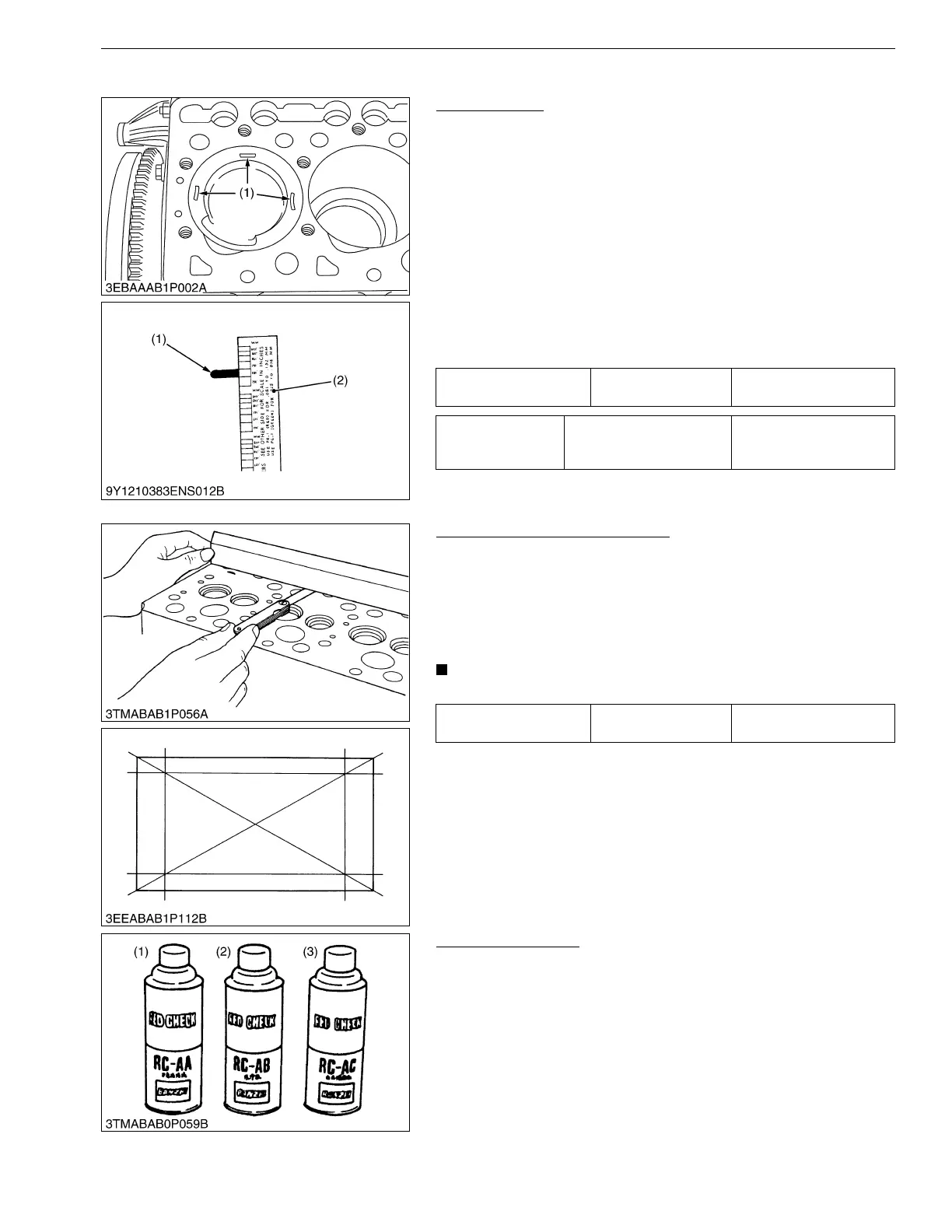

Cylinder Head Surface Flatness

1. Clean the cylinder head surface.

2. Place a straightedge on the cylinder head's four sides and two

diagonal as shown in the figure.

3. Measure the clearance with a feeler gauge.

4. If the measurement exceeds the allowable limit, correct it with a

surface grinder.

• Be sure to check the valve recessing after correcting.

9Y1211108ENS0064US0

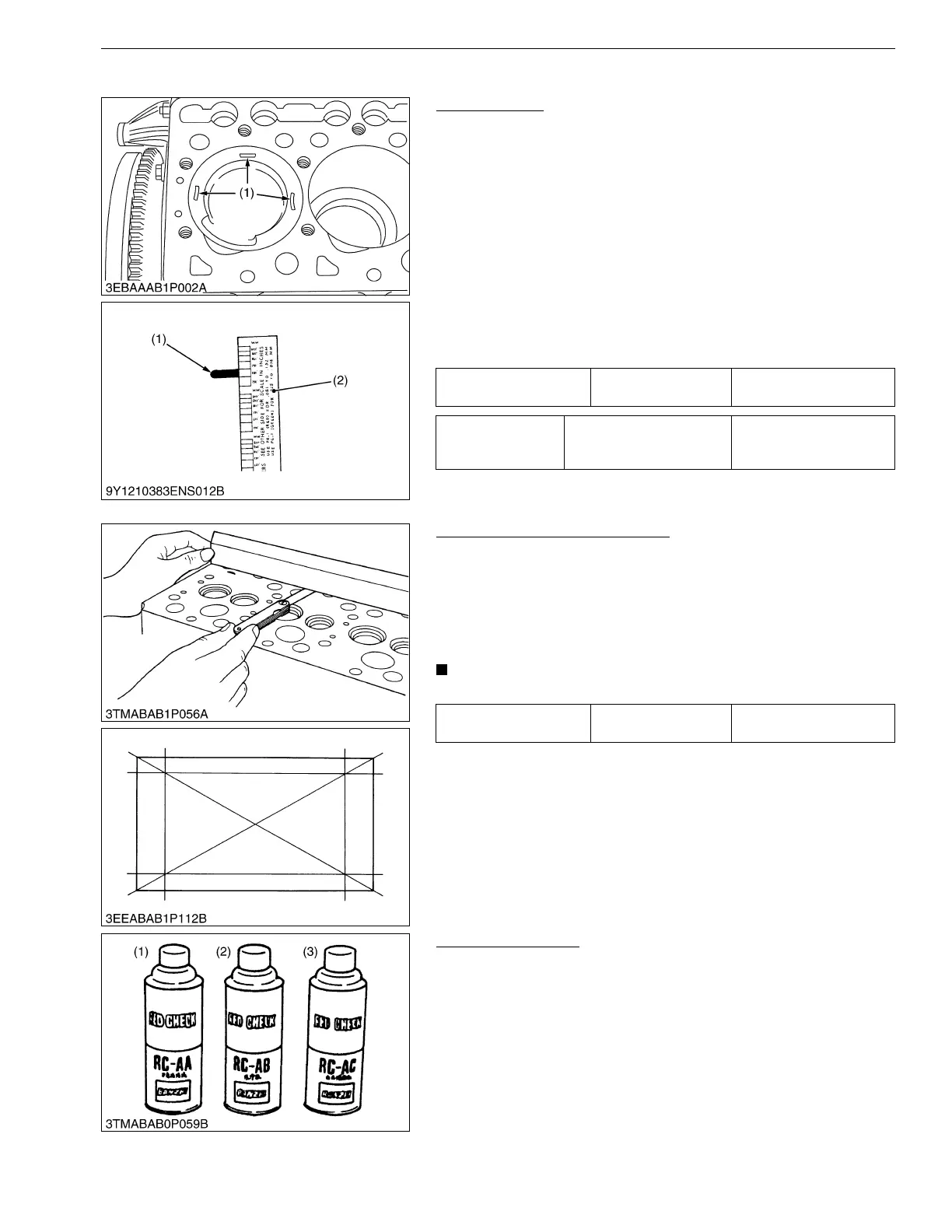

Cylinder Head Flaw

1. Prepare an air spray red check.

2. Clean the surface of the cylinder head with the detergent (2).

3. Spray the cylinder head surface with the red permeative liquid

(1). Leave it five to ten minutes after spraying.

4. Wash away the red permeative liquid on the cylinder head

surface with the detergent (2).

5. Spray the cylinder head surface with the white developer (3).

6. If flawed, it can be identified as red marks.

9Y1211108ENS0065US0

Top clearance Factory specification

1.15 to 1.35 mm

0.0453 to 0.0532 in.

Tightening torque Cylinder head screws

38 to 42 N·m

3.8 to 4.3 kgf·m

28 to 31 lbf·ft

(1) Plastigauge (2) Scale

Cylinder head surface

flatness

Allowable limit

0.05 mm

0.002 in.

(1) Red Permeative Liquid

(2) Detergent

(3) White Developer

Loading...

Loading...