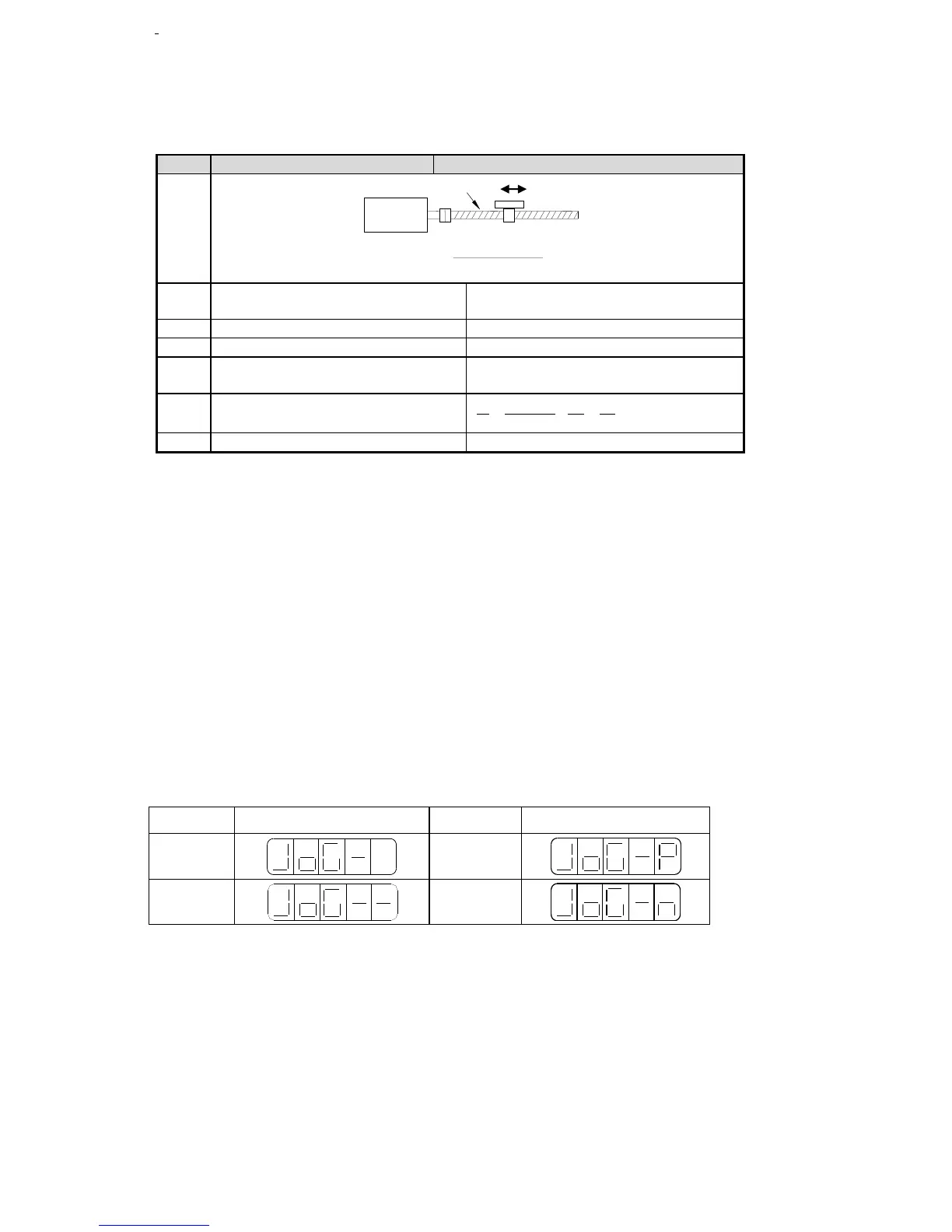

Encoder feedback signal /A+, /A-, /B+, /B-

Calculate the electronic gear ratio

Confirm the mechanical specification

Confirm the encoder pulse number

Calculate the motion value of load

shaft rotate 1 circle

Calculate the electronic gear ratio

B 2500 4 40 80

A 5000 1 1

Parameter setting

Running mode: P0-01=6

Pulse command state: P2-00=2

Electronic gear ratio: P2-02=80 P2-03=1

Forward torque limit: P4-02=150

Reverse torque limit: P4-03=150

Positioning finished width: P5-00=7

/S-ON: P5-10=0010

/CLR: P5-24=0001

/COIN: P5-28=0001

/CLT: P5-32=0002, P5-37=0000

Debug

1. Initial debug

(a) Connect the cables correctly. Connect U, V, W, PE one-to-one, don’t cross them.

(b) open-loop test-running: power on, set F1-01=1, check if the motor can work normally. If yes, enter

F1-00. If not, check the cables.

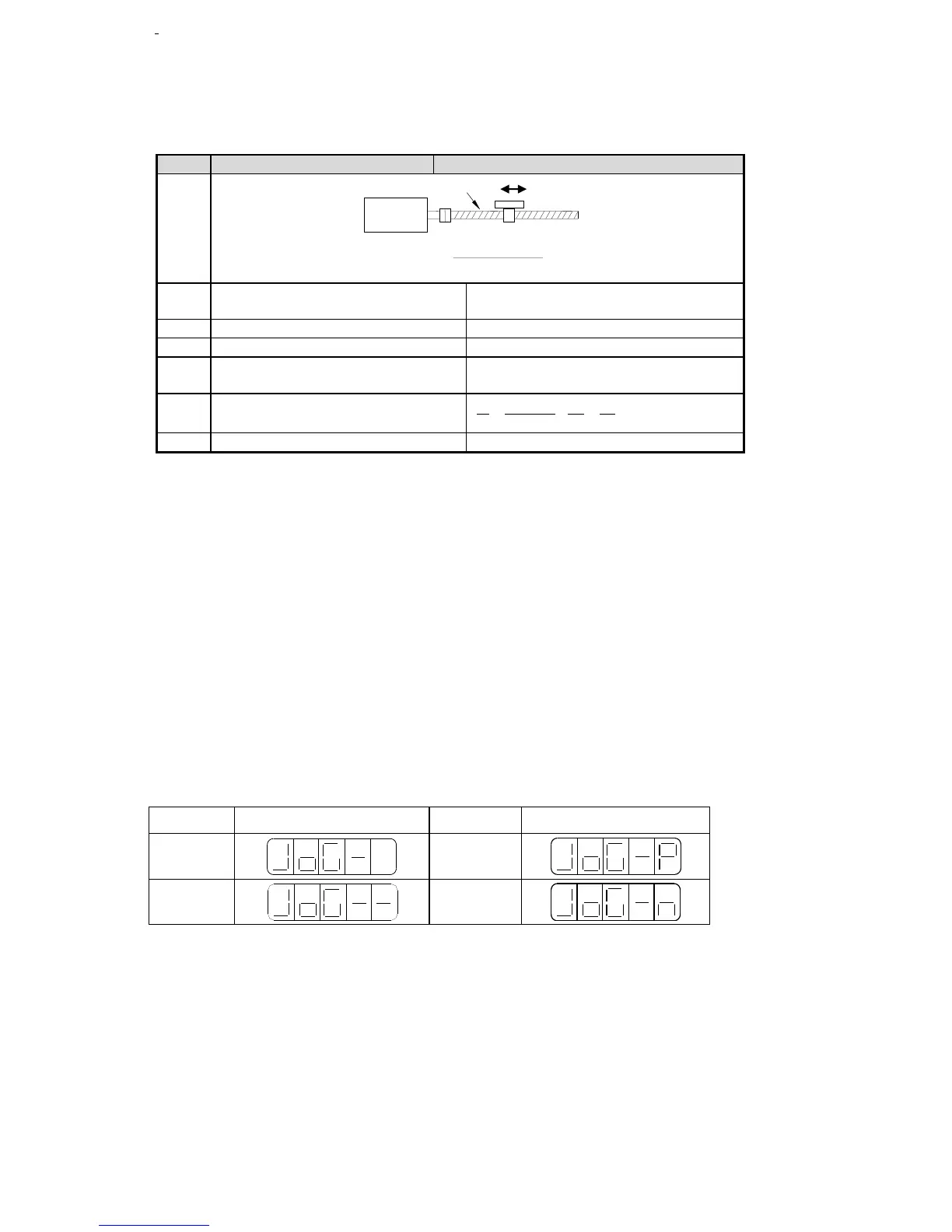

(c) Jog test-running: enter F1-00. Press ENTER to enable the motor. Press INC for forward jog, press

DEC for reverse jog. Press STATUS/ESC to quit the jog running.

4 states when jogging:

(d) Current check offset auto-adjustment

Enter F1-02, it shows rEF.

Press ENTER, it shows rEF and flickers.

After 5s the auto-adjustment finished, it shows donE.

Press STATUS/ESC to exit.

2. Debug the motor with machine

(a) Check the motor rotation direction, if it is reverse from the actual needs, set F1-05 to 0 (servo force

OFF). Then set P0-05 to 1, re-power on the servo.

(b) Check the servo stability and response, adjust the servo gain.

3. Debug with PLC program.

Loading...

Loading...