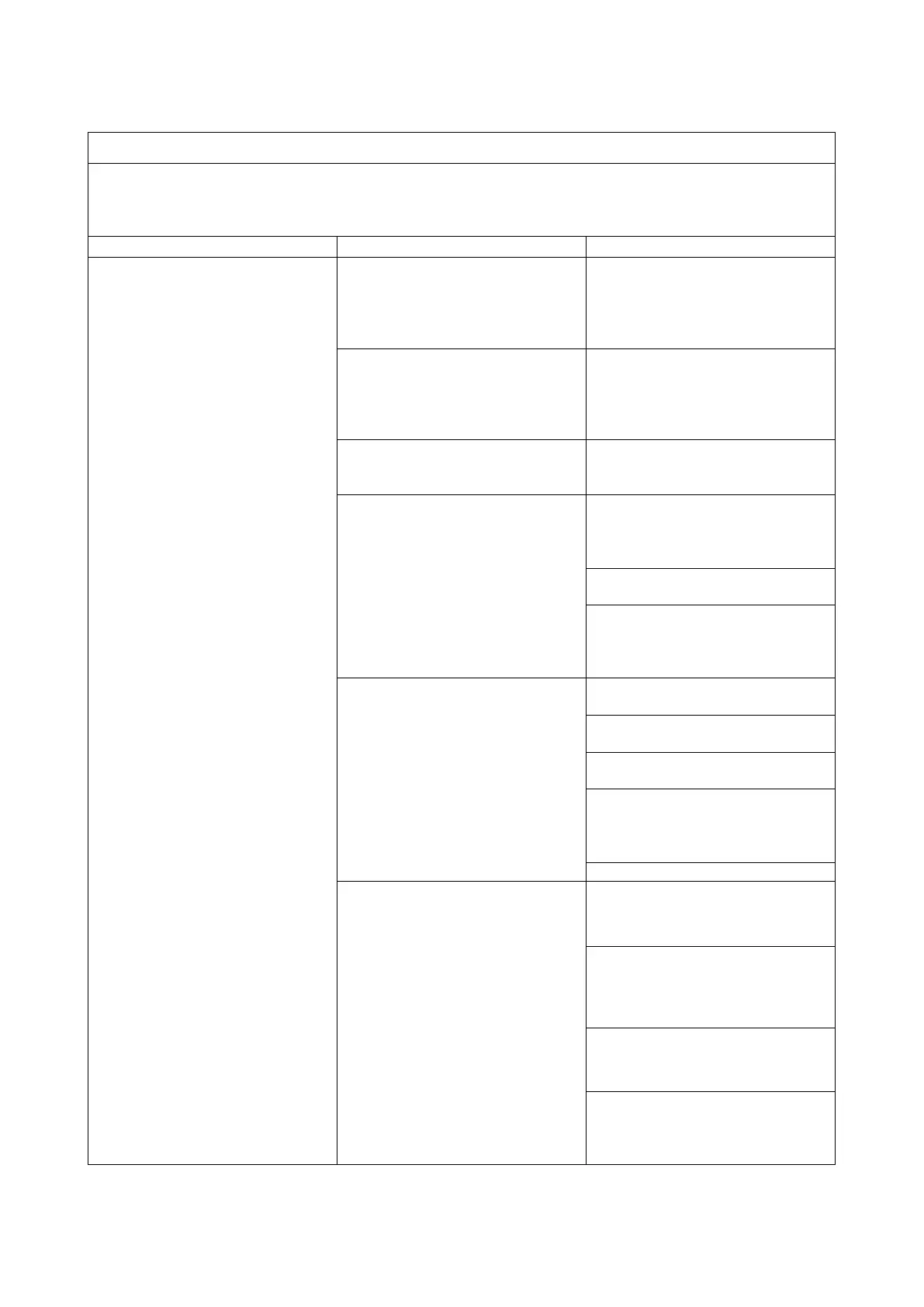

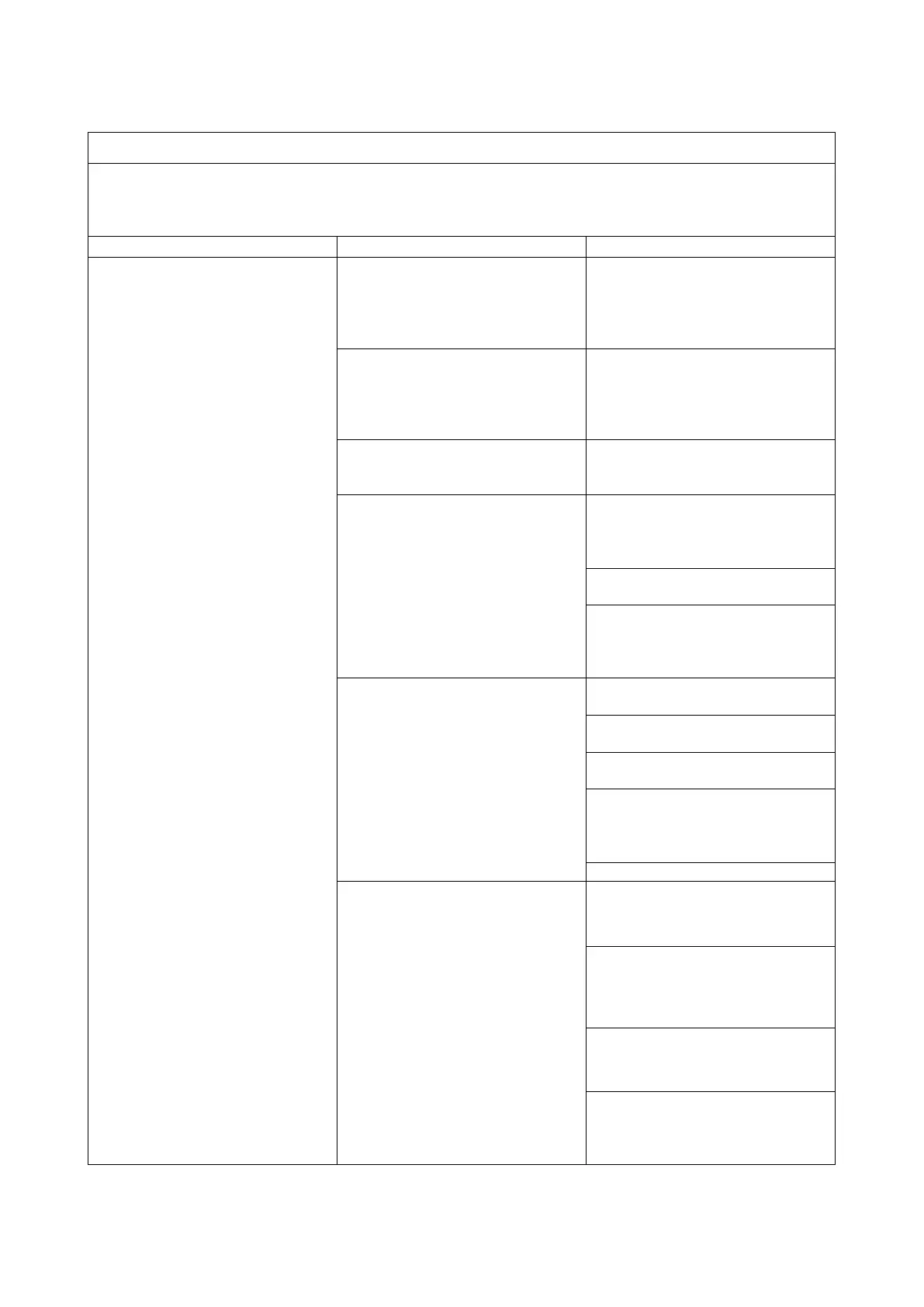

XO 4 & XO FLEX TROUBLE SHOOTING GUIDE

Version 3.30 62

The backflow Prevention System is designed to avoid any risk of water contamination after mixing.

The system is maintained the container under pressure after filling. The system consists of a mixing cup,

a sensor, a backflow prevention tank equipped with non-return valve, air and water inlet pipes and two

No water in the container.

The check valve is defective.

Unscrew and remove the mixing

cup from above the container to

access the check valve. Unscrew

the plug and clean or replace it

It is very important that the check

valve is mounted correctly to

avoid any backflow into the

bucket when the container is

Sensor pins are not properly

placed in the mixing cup or are

Refer to chapter "Liquid sensor

PCB” AP-869" on page 54

The water supply valve V27 is

defective

Verify that the connectors are

properly inserted.

Measure the voltage at the coil

Measure the coil resistance

(≈100Ω).

Disassemble and clean the valve

at the piston.

Change the plunger seat gasket

The 3-way air supply valve V30

for pressurized air is defective

Check the voltage 24VDC on the

valve connectors.

Verify that the connectors are

properly inserted.

Measure the coil resistance

(≈100Ω).

Disassemble and clean the valve

at the piston.

Change the plunger seat gasket

replace if faulty, AO-777

The main water valve V10 (Ø3, 2-

way, 1/8RG) is defective.

WATER/AIR XO4 and XO Flex

Page 52 for explanation.

Verify that the connectors are

properly inserted.

Measure the voltage at the coil

connectors 24VDC

Measure the coil resistance

(≈100Ω).

Change if defective UC-584.

Disassemble and clean the valve

at the piston.

Change the plunger seat gasket

Loading...

Loading...