VESDA by Xtralis VESDA Pipe Network Installation Guide

www.xtralis.com 19

5.1.3 Floor Void Installation

Installations in the under floor void require considerations similar to the In-Ceiling Void Installation.

Figure 5-3: Typical under floor installation

The Guidelines to be followed for Floor Void Installations include:

1. Refer to the guidelines for In-ceiling installations for general guidelines.

2. Supporting posts can be used to secure the pipe.

3. As the initial smoke layer normally takes up the top 10% of the void height, pipes should be placed as

close to the floor as possible.

4. Secure the pipe using appropriate conduit clamps or self locking ties ensuring that the distance

between the floor and the pipe is according to the design specification. For further information, refer to

Section 3.9 on page 10.

5.1.4 Inter-beam

Inter-beam sampling is used in areas having large beams as defined by local fire code and standards, or as per

site requirements. Design documents will specify the requirement for inter-beam sampling.

The three methods for inter-beam sampling are:

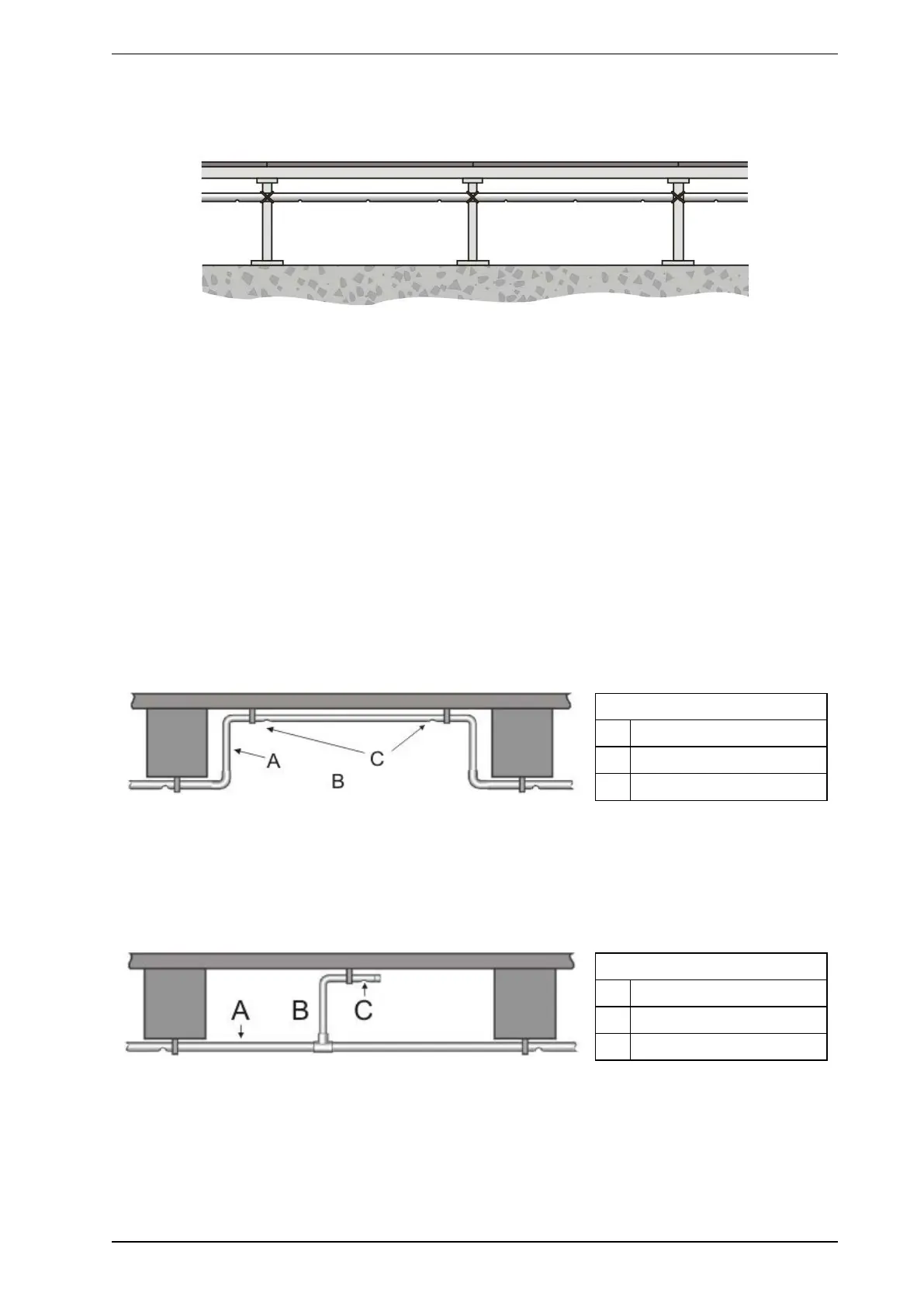

Sampling Pipe Traversing inside of the Beam Pocket - Bend the sampling pipe, where the depth of the

beam allows the pipe to be bent without it cracking or crinkling (refer to Section 4.5 on page 15).

Legend

A Sampling Pipe

B Beam Pockets

C Sampling holes

Figure 5-4: Inter-beam sampling using pipe bends

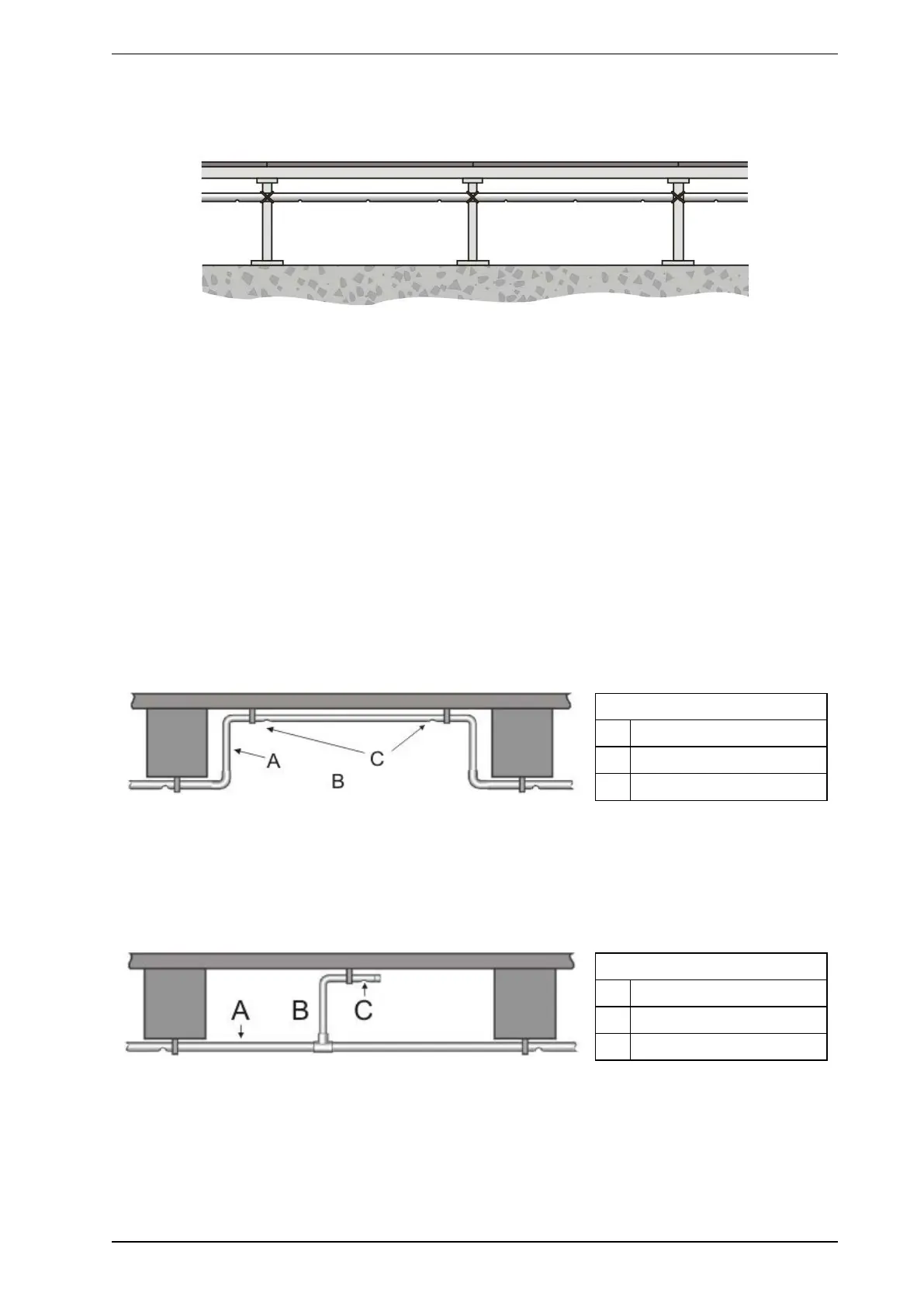

Walking Sticks - Walking sticks are attached to the sampling pipe. The walking stick is a length of riser pipe.

Attach a bend or an elbow at the top end of the riser pipe. Fix an appropriate length of pipe to the bend or elbow

and drill a sampling hole (as specified in the design documents) into the pipe. Close the end of the pipe with an

end cap. Attach the walking stick to a Tee adaptor using a reducing connector (if required). Join the Tee to the

sampling pipe at the specified spot.

Legend

A Sampling Pipe

B Beam Pockets

C Sampling holes

Figure 5-5: Inter-beam sampling using a walking stick

Underside of the Beams - Run the sampling pipe with sampling holes facing down, along the underside of

the beams.

Loading...

Loading...