4 Preparation for startup

You must follow these precautions before you start the pump:

• Flush and clear the system thoroughly to remove dirt or debris

in the pipe system in order to prevent premature failure at ini‐

tial startup.

• Run a new or rebuilt pump at a speed that provides enough

flow to flush and cool the close-running surfaces of the stuffing

box bushing.

• If temperature of the pumped fluid will exceed 200°F (93°C),

then warm up the pump prior to operation. Circulate a small

amount of fluid through the pump until the casing temperature

is within 100°F (38°C) of the fluid temperature.

WARNING:

• Operating the pump in reverse rotation can result in the contact of

metal parts, heat generation, and breach of containment.

• Always disconnect and lock out power to the driver before you

perform any installation or maintenance tasks. Failure to discon‐

nect and lock out driver power will result in serious physical injury.

Check Drive Rotation:

1. Unlock power to the driver.

2. Make sure that everyone is clear, and then jog the driver long

enough to determine that the direction of rotation corresponds

to the arrow on the pump.

3. Lock out power to the driver.

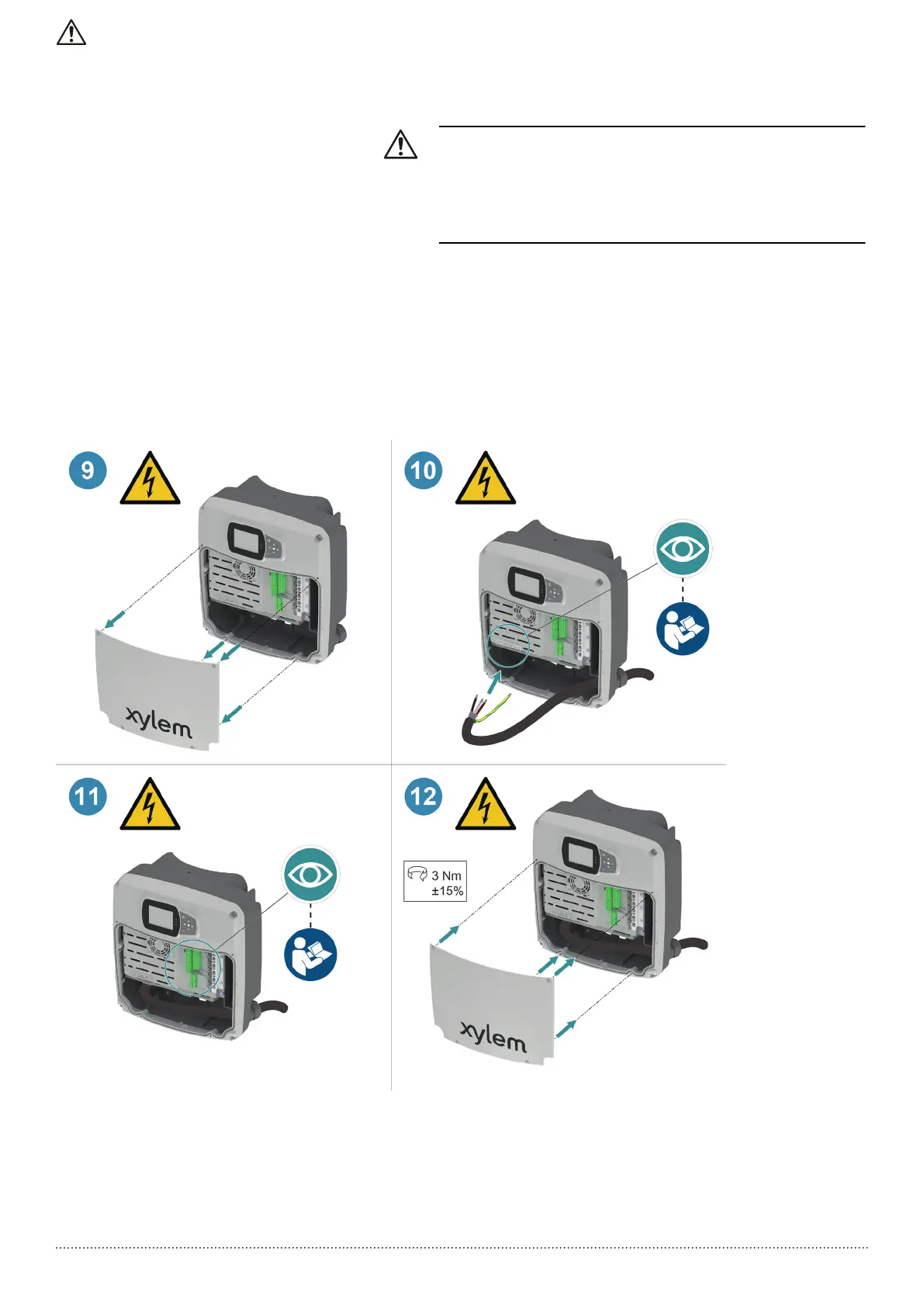

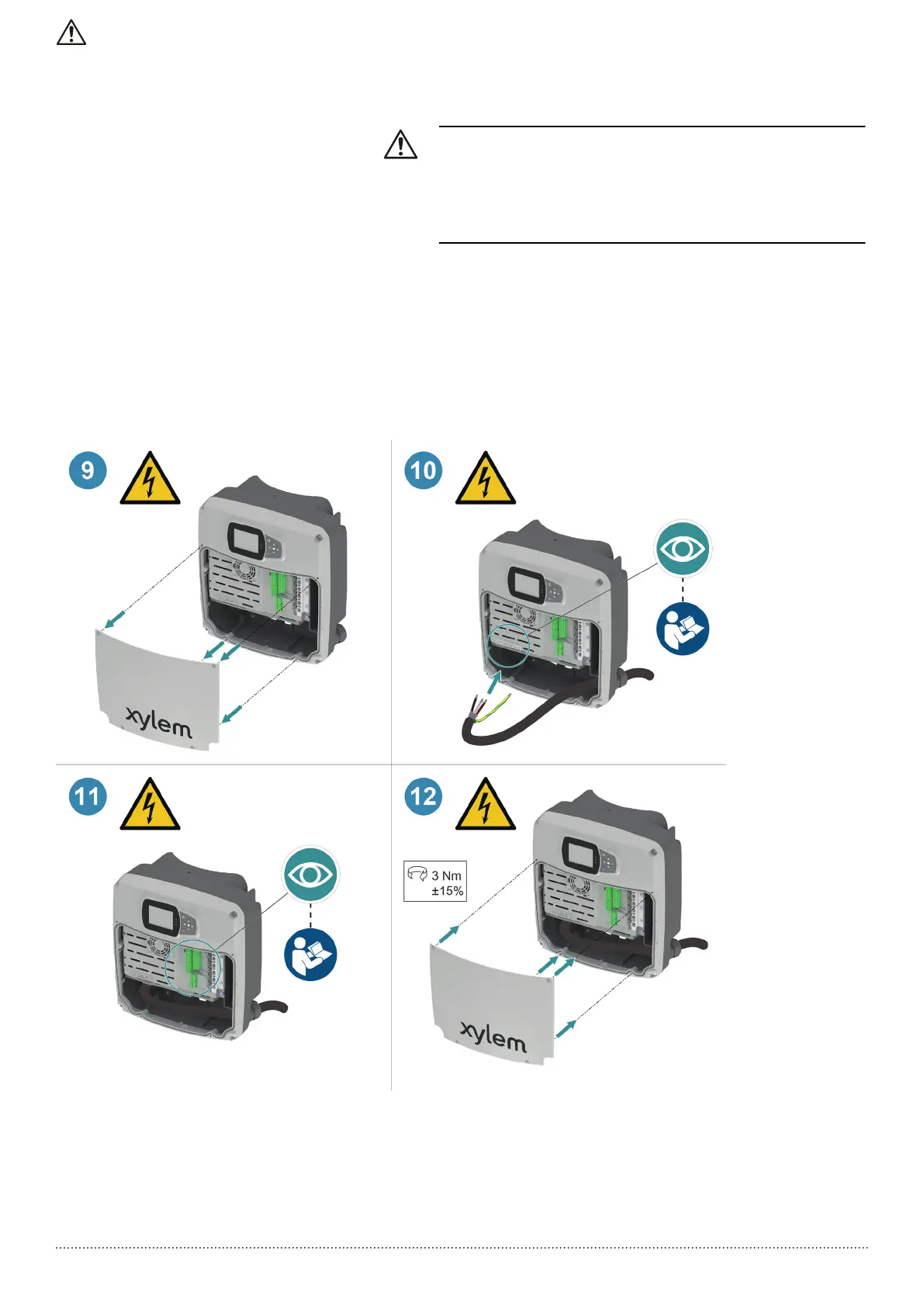

5 Electrical installation

Figure 1

For safety and correct product usage, read the manual before this product is used.

3

Loading...

Loading...