1800 YRM 1005 Brake Assembly Repair

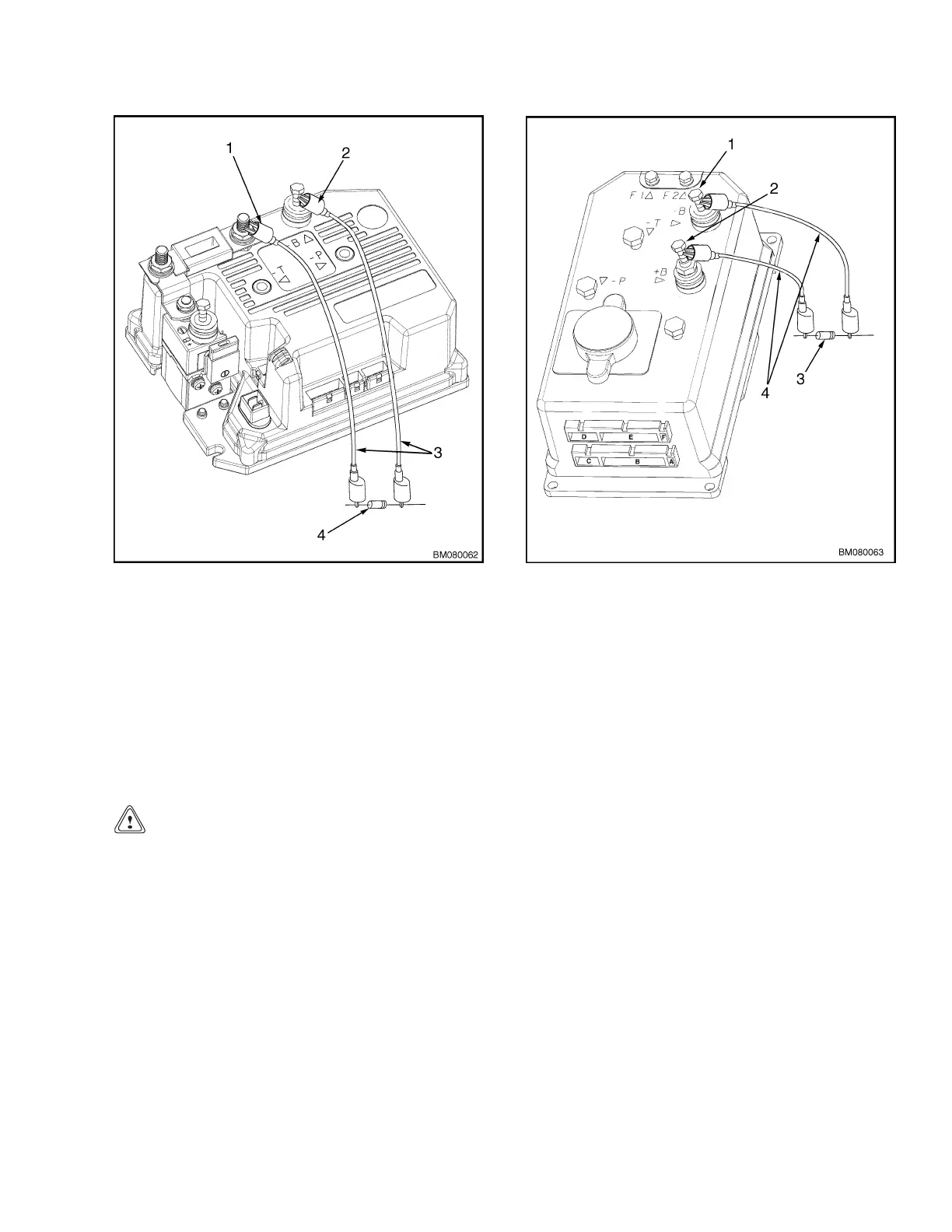

1. POSITIVE CONNECTION

2. NEGATIVE

CONNECTION

3. INSULATED JUMPER WIRES

4. 200-OHM, 2-WATT RESISTOR

Figure 2. Discharging Controller MPB040-E

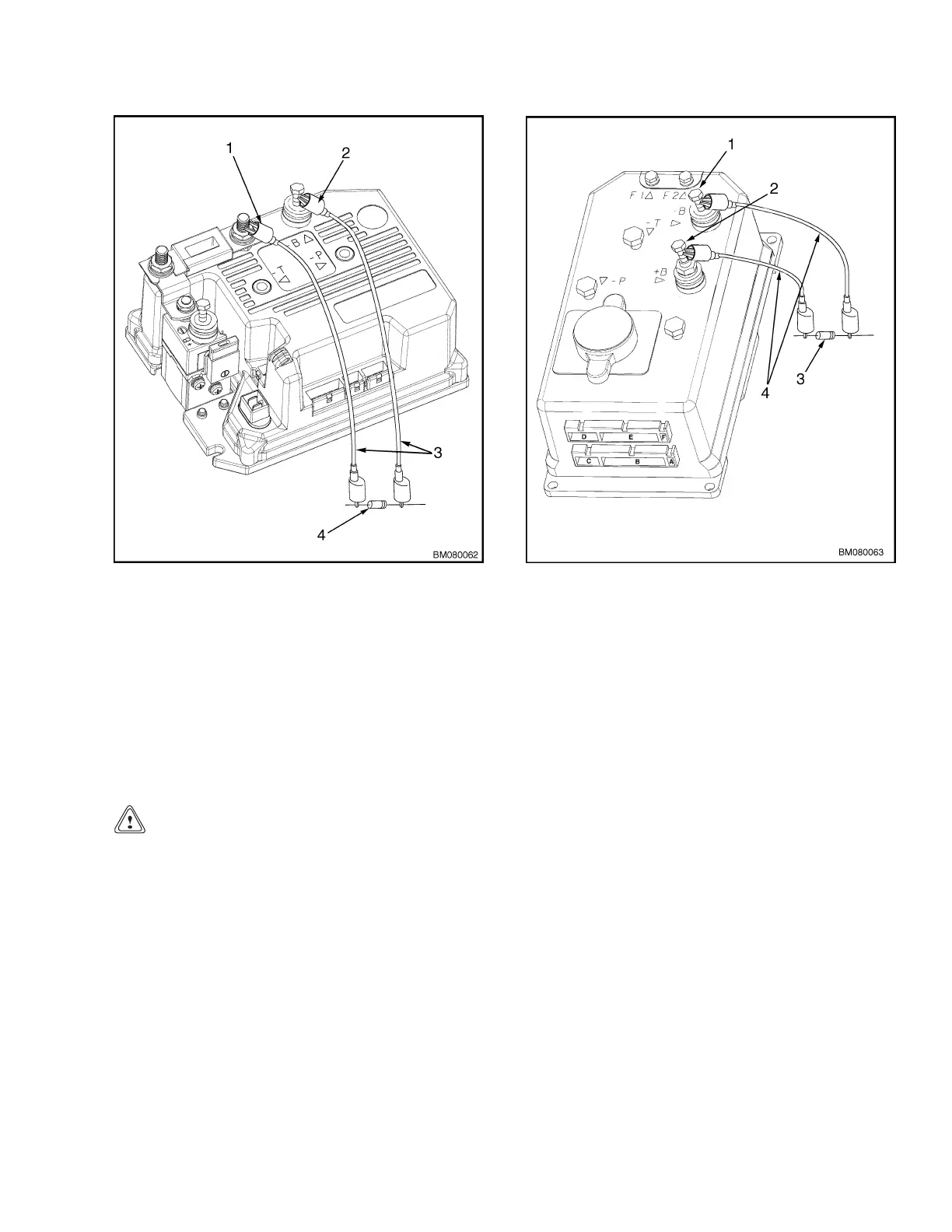

1. NEGATIVE CONNECTION

2. POSITIVE

CONNECTION

3. 200-OHM, 2-WATT RESISTOR

4. INSULATED JUMPER WIRES

Figure 3. Discharging Controller MSW020/025-E,

MSW025/030-F, and MPW045/050-E

Brake Assembly Repair

BRAKE OVERRIDE

CAUTION

Never operate the lift truck while the brake override

feature is being used.

The brake can be disengaged when a truck cannot be

operated but needs to be moved. On the main wiring

harness approximately 300 mm (12 in.) above the

MDU, the brake wiring harness is connected. An extra

four pin connector for the brake override feature is

secured near this connection with wire ties. Disconnect

the connectors and connect the brake wiring harness

to the brake override connector. This will energize

the brake coil which will release the brake. The drive

motor will not activate while the jumper is installed.

Roll the lift truck to a safe location and disconnect

the brake override connector. The brake will apply

when the brake override connector is disconnected or

when power to the brake override circuit is interrupted.

Reconnect the brake wiring harness to the main wiring

harness and proceed with repairs. If the battery does

not have sufficient charge, or if certain components of

the lift truck are damaged, the brake may not release

with the brake override circuit engaged. In this case,

the malfunction must be corrected before the brake can

be released. See Figure 4.

3

Loading...

Loading...