SINGLE-CYLI

ND

ER

ENGINES

91

3. Remove the drive disc (Figure 68).

4. Gradually loosen and remove the flywheel bolts,

working in a diagonal pattern. Install two drive disc bolts

into two outer holes in the flywheel

(Figur

e 69), then use

the screws to pull and remove the flywheel.

5. Inspect the ring gear. If the ring gear is excessively

worn or damaged, usc the following procedure to remove

the ring gear:

a. Heat the ring gear evenly, then drive the ring gear

off

the flywhee l.

b. Heal the ring gear prior to installation. Drive the

ring gear onto the flywheel, being careful not to

damage the g

ear

teeth.

6. Reverse the removal procedure to install the flywheel.

Tighten the flywheel retaining bolts to the torque speci-

fied in Table 2. Refer to Chapter Ten to install the drive

disc and transmission.

DRIVE

DISC

Refer to Chapter Ten for drive disc procedures (Figure

68).

CRANKSHA

FT

Removal and Installation

Refer to Figure 70.

1. Remove the flywheel as previously described.

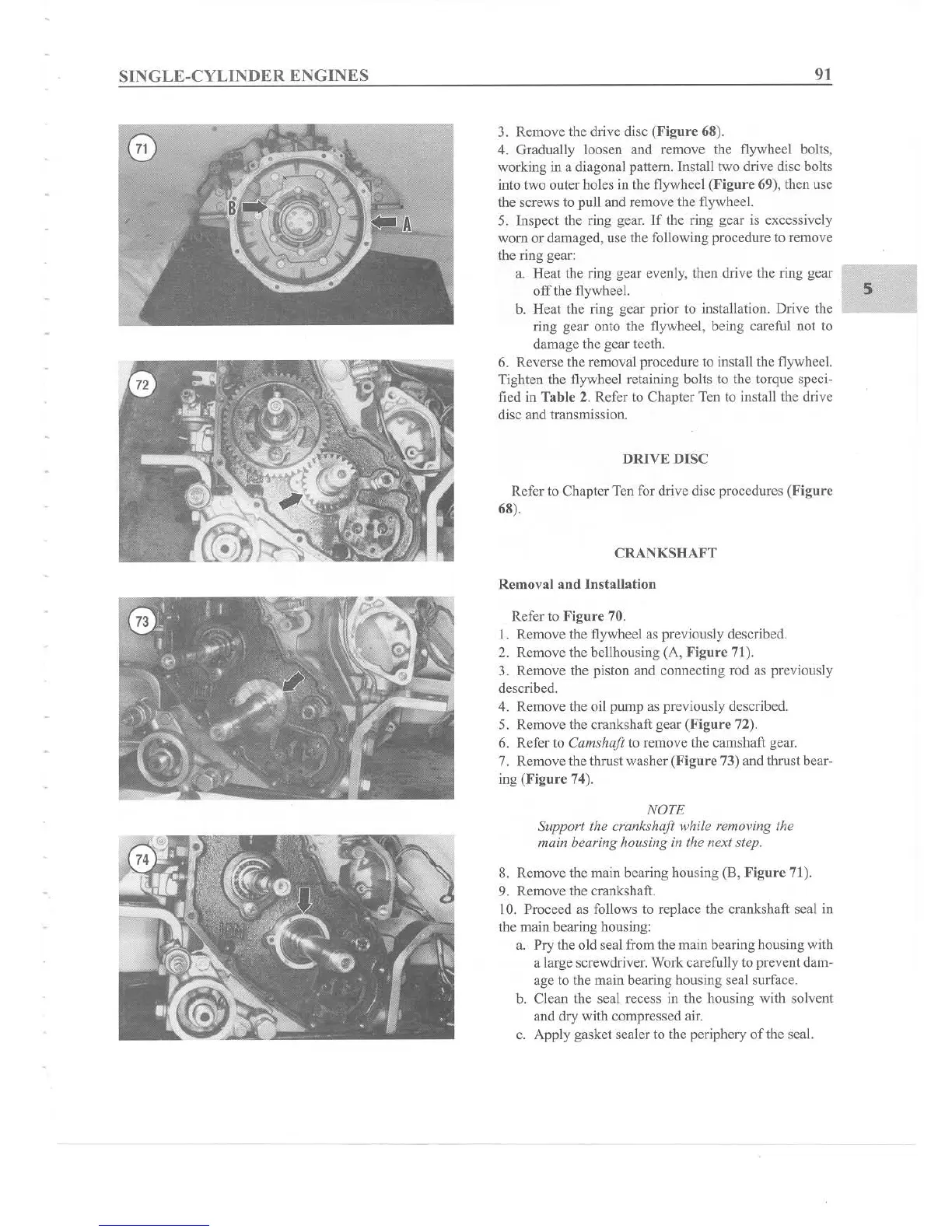

2. Remove the bellhousing (A, Fig

ure

71).

3. Remove the piston and connecting rod as previously

described.

4. Remove the oil pump as previously described.

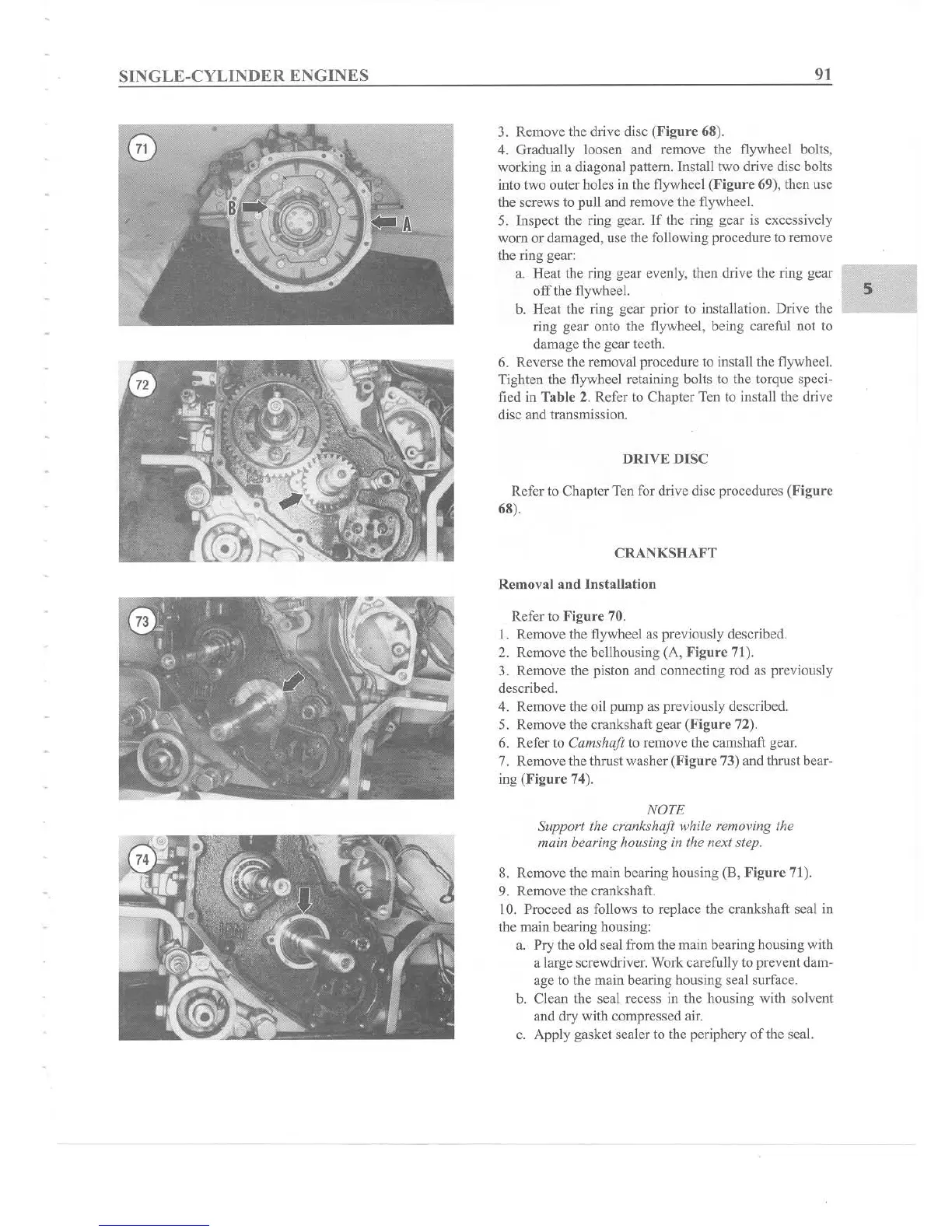

5. Remove the crankshaft gear (Figure 72).

6. Refer to Camshaft to remove the camshaft gear.

7. Remove the thrust washer (Fig

ure

73) and thrust bear-

ing

(Figur

e 74).

NOTE

Support the crankshaft while removing the

main bearing housing in the next step.

8. Remove the main bearing housing (8, Fig

ure

71).

9. Remove the crankshaft.

10. Proceed as follows to replace the crankshaft seal in

the main bearing housing:

a. Pry the old seal from the main bearing housing with

a large screwdriver. Work carefully to prevent dam-

age to the main bearing housing seal su

rf

ace.

b. Clean the seal recess in the housing with solvent

and dry with compressed air.

c. Apply gasket sealer to the periphery

of

the seal.

5

Loading...

Loading...