92

B

A

d. Position the new seal in the housing recess with its

open end facing the inside

of

the bearing hous ing.

Drive the seal into place

with a suitably sized seal

driver.

II.

Refer to Main Bearings for information con cern ing

inspection

of

the main bearings and thrust bearings.

12. Reinstall the crankshaft by reversing the removal

procedure white noting the followi ng:

a. Thoroughly lubricate the main bearings and thrust

bearings.

b. Install the inner, front thrust bearing so the oil

grooves arc

toward the inside

of

the crankcase and

the tab fils into the recess (Fig

ur

e 75) in the cran k-

case. Apply a light coating

of

grease to hold the

thrust bearing in place.

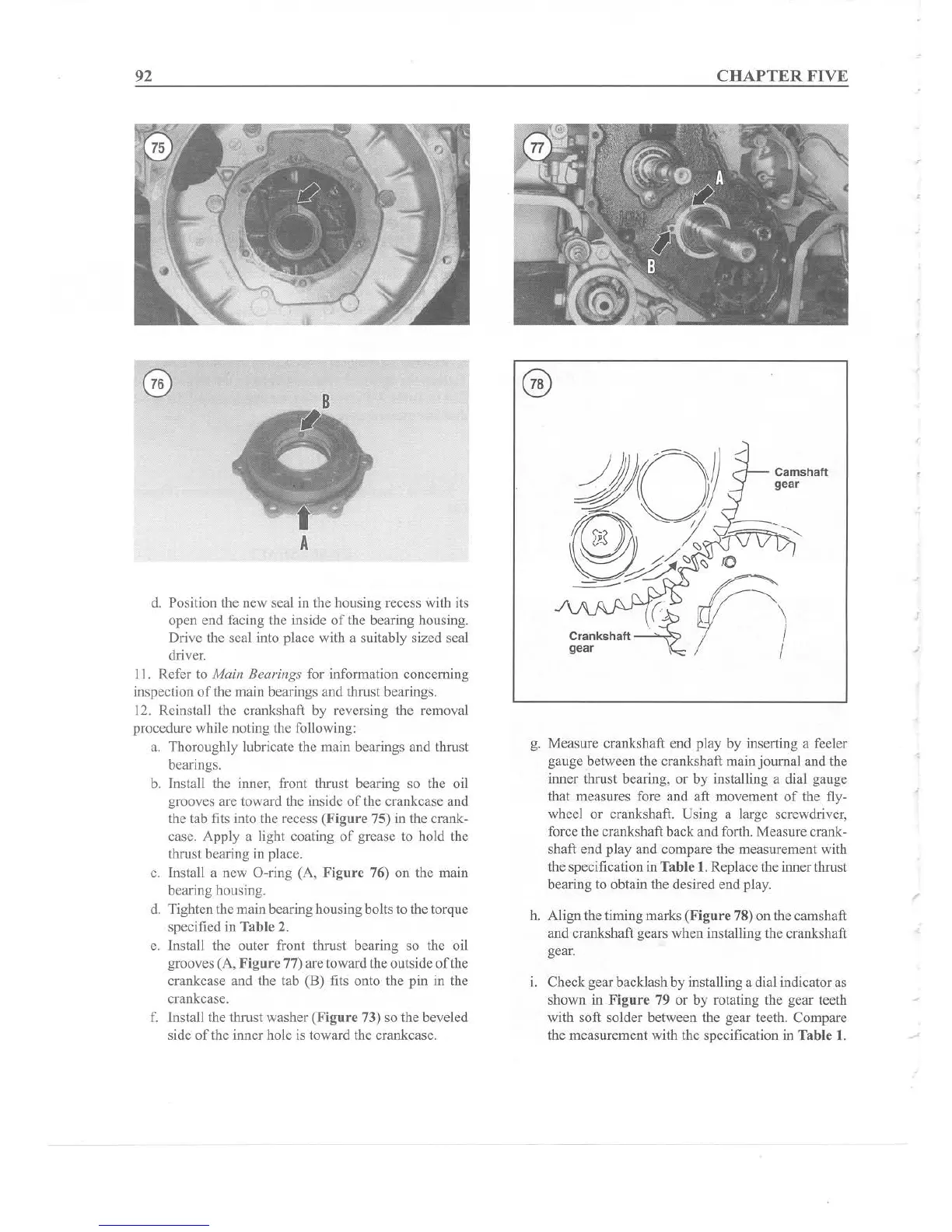

c. Install a new O-ring (A, Figure 76) on the main

bearing housing.

d. Tighten the main bearing housing bolts to the torque

specified in Table 2.

e. Install the outer front thrust bearing so the oil

grooves (A,

Figur

e 77) are toward the outside

oft

he

crankcase

and

the tab (B) fits onto the pin in the

crankcase.

f. Install the thrust washer (Figure 73) so the beveled

side

of

the inner hole is toward the crankcase.

-----

CHAPTER

FIVE

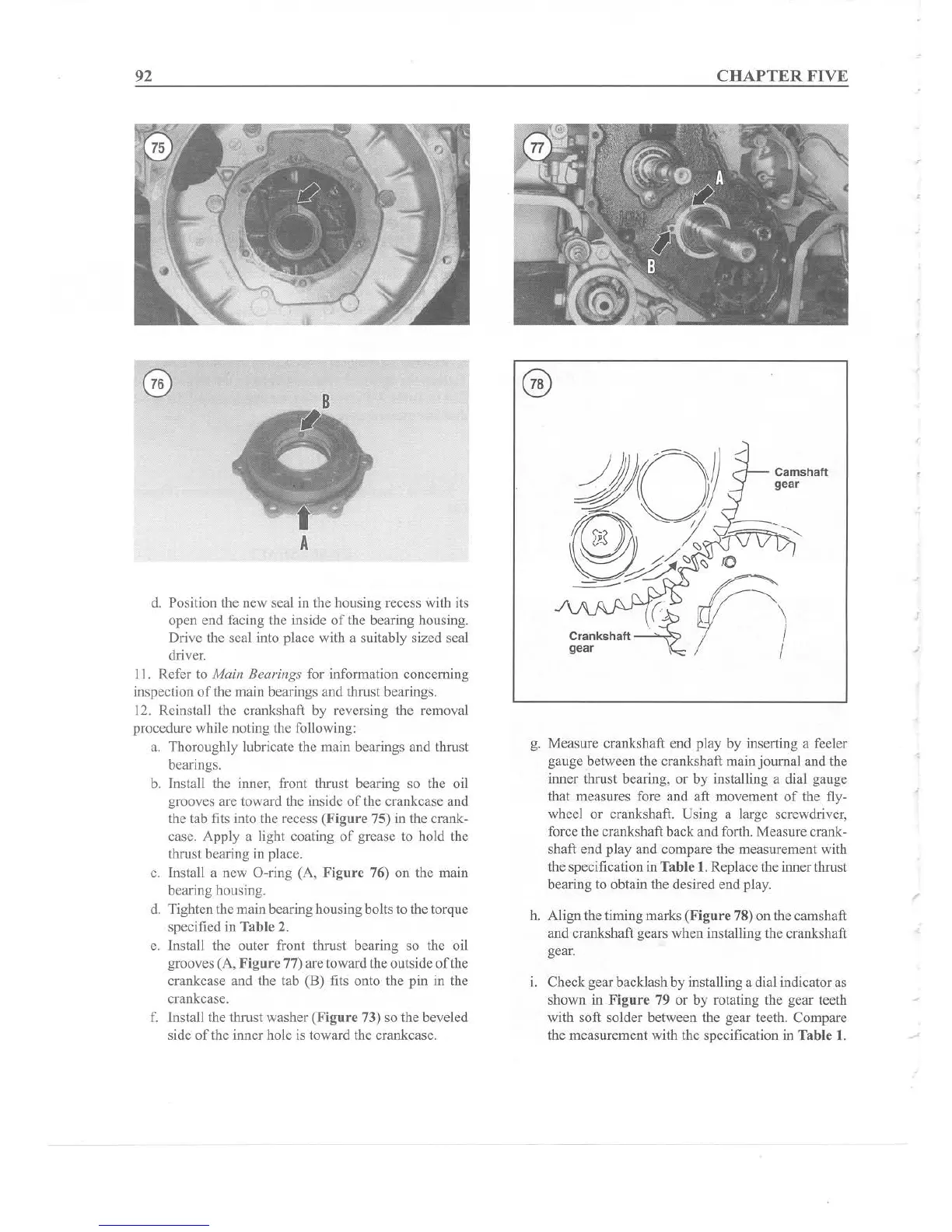

Cam shaft

gear

g. Measure crankshaft end play by inserting a feeler

gauge between the crankshaft main journal and the

inner thrust bearing, or by installing a dial gauge

that measures fore and aft movement of the fly-

wheel or crankshaft. Using a large screwdriver,

force the crankshaft back and forth. Measure crank-

shaft end play and compare the measurement with

the specification in Ta ble 1. Replace the inner thrust

bearing to obtain the des ired end play.

h. Align the timing marks

(Figure 78) on the camshaft

and crankshaft gears when installing the crankshaft

gear.

l. Check gear backlash by installing a dial indicator as

shown in Figure 79 or by rotating the gear teeth

with soft solder between the gear teeth. Compare

the measurement with the specification in Table

I.

Loading...

Loading...