37

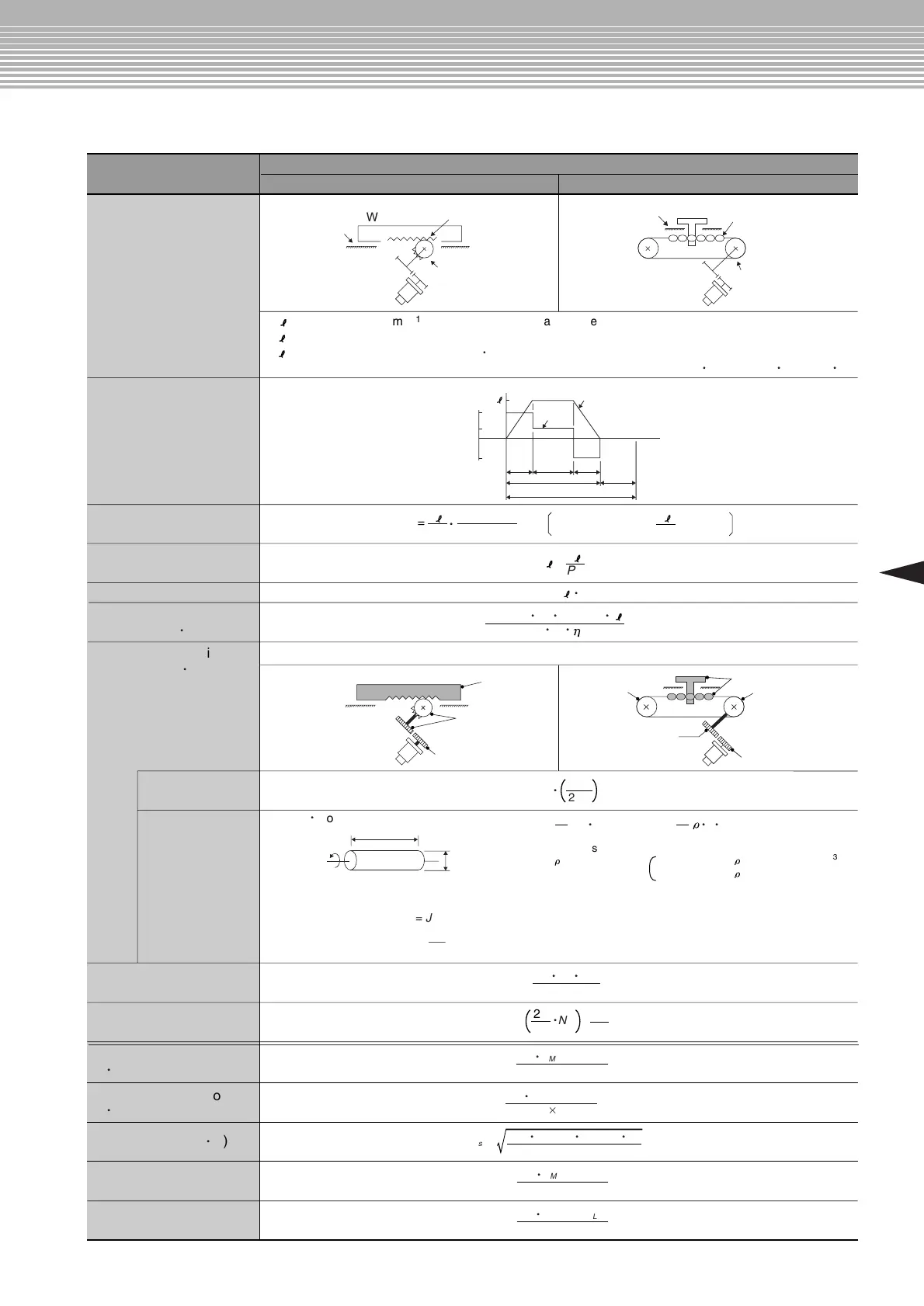

<Inertia for motor shaft>

At gear input side

At gear output side

J

L2

J

L1

J

L1

J

L3

J

L3

J

L3

J

L2

J

L3

2

P

B

J

L1

=

M

2π

R

or

Linear Motion

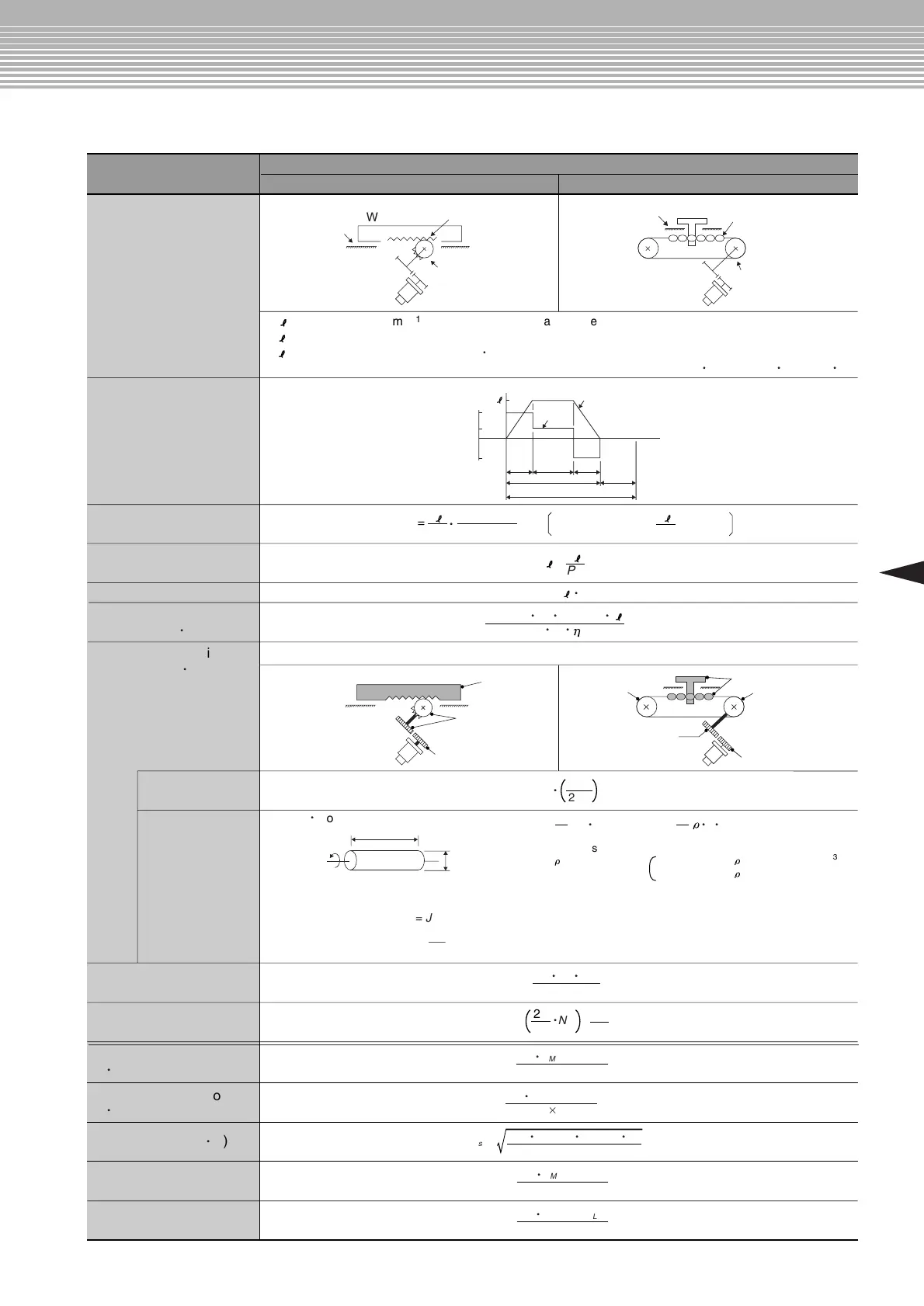

Rack & Pinion Chain and Timing Belt

Speed

Speed

Torque

Torque

Cycle time

t

(

s

)

0

2π

N

M

(

J

M

+

J

L

)

2

Solid cylinder

8

1

32

L

(m)

V

T

p

T

L

T

S

t

a

t

c

t

m

t

e

t

d

N

=

N

M

=

N

R

V

P

B

R =

(

tm

–

ta

)

Where

t

a

=

t

d

,

d

p

: Pitch diameter (m)

Z

p

: Number of gear

L

p

: Pitch (m)

P

B

= Zp

Lp or π

dp

R =

60 2

Vt

a

+ 2

t

c

+

t

d

60

V

T

L

=

J

L

=

J

L1

+

J

L2

+

J

L3

J

K

=

M

K

D

2

J

K

=

L

D

4

J

L2

=

J

K

J

L3

=

J

K

R

2

t

am

=

2π

N

M

(

J

M

+

J

L

)

t

dm

=

2π

N

M

T

L

60

P

0

=

2π

60

N

M

P

a

=

J

L

t

a

2π

N

M

(

J

M

+

J

L

)

60

×

t

a

T

P

=

+

T

L

2π

N

M

(

J

M

+

J

L

)

60

×

t

d

T

S

=

–

T

L

T

P

2

t

a

+

T

L

2

t

c

+

T

S

2

t

d

T

rms

=

t

D

(m)

1/R

W

1/R

dp, Zp

dp, Zp

W

Lp

Lp

Selection of Servomotor Size

Motions

Mechanical Configuration

Speed Diagram

Travel Distance (m)

Min. Starting Time

(

S

)

Min. Braking Time

(

S

)

Running Power

(

W

)

Acceleration Power

(

W

)

Load axis speed

(min

-1

)

Motor Speed (min

-1

)

Effective Load Torque at

Motor Shaft

(

N

m

)

Required Starting Torque

(

N

m

)

Required Braking Torque

(

N

m

)

Effective

Torque

(

N

m

)

Effective Load Inertia at

Motor Shaft (kg

m

2

)

Linear Motion

M

K

: Mass (kg)

: Density (kg/m

3

) Iron

Aluminum

Rotational Motion

2π

R

µ

µ

: Load axis speed (min

-1

)

: Load speed (m/min)

:

Effective load torque at motor shaft (N

m)

: Friction coefficient

µ

N

V

T

π

9.8

×

M

P

B

+ 2π

T

µ

60

(

T

M

–

T

L

)

M

:

Mass of linear-motion unit (kg)

1/R

:

Gear ratio

η

:

Combined efficiency

T

M

:

Servomotor maximum torque (N

m)

60

(

T

M

+

T

L

)

= 7.87 × 10

3

(

kg/m

3

)

= 2.70

× 10

3

(

kg/m

3

)

Loading...

Loading...