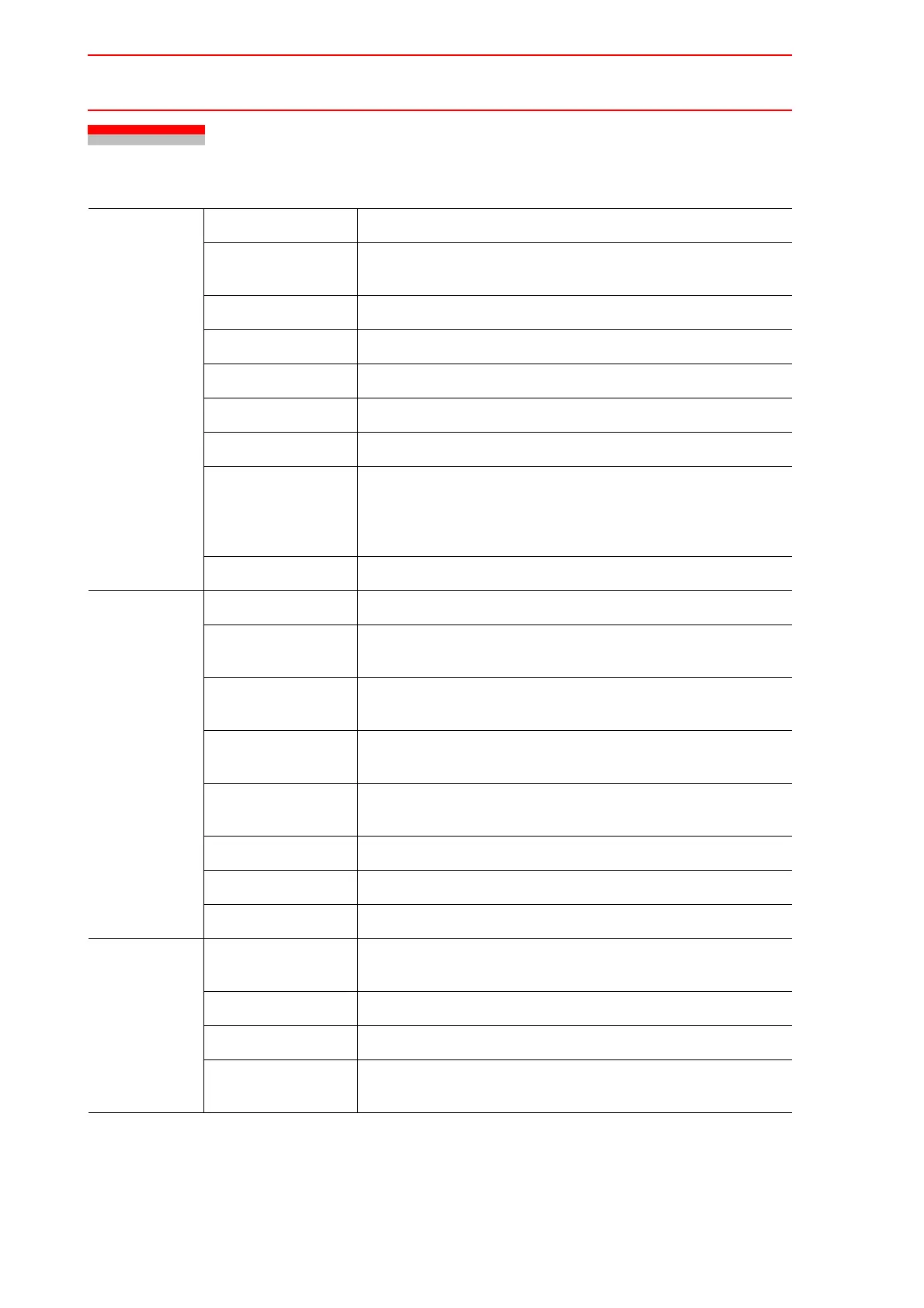

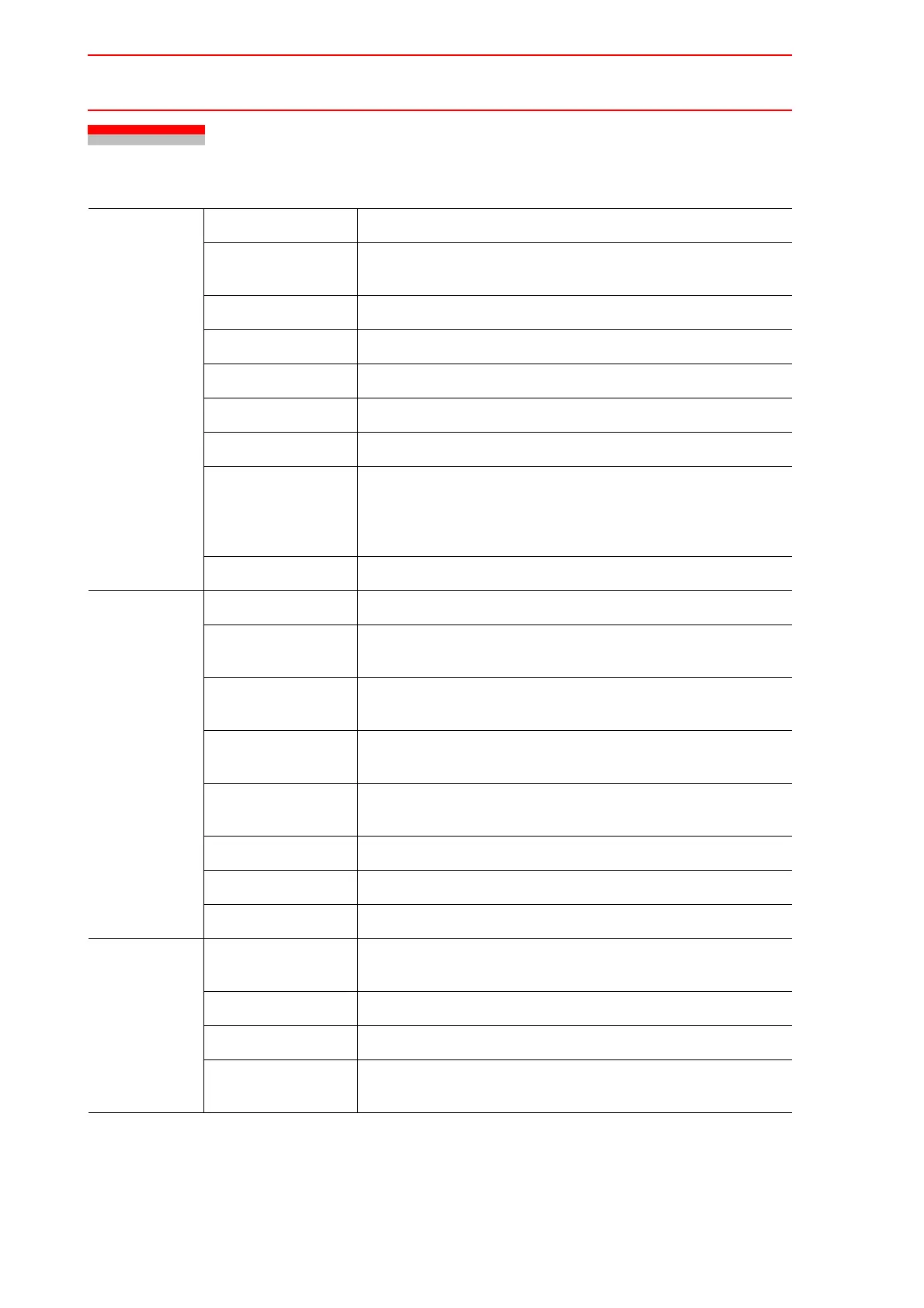

6.2 Function List

6-4

6.2 Function List

Programming

Pendant

Operation

Coordinate System Joint, Rectangular/Cylindrical, Tool, User Coordinates

Modification of

Teaching Points

Adding, Deleting, Correcting (Robot axes and external axes

respectively can be corrected.)

Inching Operation Possible

Path Confirmation Forward/Reverse step, Continuous feeding

Speed Adjustment Fine adjustment possible during operating or pausing

Timer Setting Possible every 0.01 s

Short-cut Function Direct-open function, Screen reservation function

Interface CF (Compact Flash) card slot (At Programming Pendant)

RS232C (At Control Circuit Board)

LAN (100 BASE-TX/10BASE-T) (At Control Circuit Board)

(Option)

Application Arc welding, Spot welding, Handling, General, Others

Safety

Feature

Essential Measures Designed in accordance with UL, ANSI/RIA standard

Running Speed

Limit

User definable

Enable Switch 3 position type. Servo power can be turned on at the middle

position only. (Located on programming pendant)

Collision-proof

Frames

S-axis frame (doughnut-sector), Cubic frame (user coordi-

nate)

Self-Diagnosis Classifies error and two types of alarms (major and minor)

and displays the data

User Alarm Display Possible to display alarm messages for peripheral device

Machine Lock Test-run of peripheral devices without robot motion

Door Interlock A door can be opened only when a Disconnect switch is off.

Maintenance

Function

Operation Time

Display

Control power-on time, Servo power-on time, Playback time,

Operation time, Work time

Alarm Display Alarm message and previous alarm records

I/O Diagnosis Simulated enabled/disabled output possible

T.C.P. Calibration Automatically calibrates parameters for end effectors using a

master positioner

Loading...

Loading...