2.6.5.3 Operation Expression for Coordinate System

Setting

The following

is the operation expression for

coordinate system setting at various time

frequencies ?

X-axis coordinate value = Machine position + tool

coordinate memory +

work coordinate system

shift amount

Z-axis coordinate value = Machine position + tool

coordinate memory +

work coordinate system

shift amount

( 1) The machine position is called the position

machine.

( 2 )

The tool coordinate memory value number is

of two types; the number when the timing for

the next coordinate system setting is manual

and when it is automatic.

(3) The work coordinate system shift amount is

called the offset TOO, X, or Z data.

2.6.5,4 Timing of Coordinate System Setting under

the Manual Mode

Under the manual mode, coordinate system setting

is made with the following times (a) to (c) .

The

tool coordinate memory number is created from the

tool number binary value set in 1/0 input #13174

(TP1) to #13178 (TP8) , to be used for operation.

The coordinate system can also be set up

inside the NC,

or by a request from the

sequencer.

When set by a request of the

sequencer, coordinate system setting is executed

to turn on output #12194 (end of coordinate system

setting output) when

input #13127 (coordinate

system setting request input) turns on.

(a) Upon zero point return. (NC internal setting

at label skip, or sequencer setting for other

cases. )

(b) On the tool

setter, when the tool nose

contacts the sensor upon measurement.

(NC

internal setting)

(c) When turret indexing is performed by manual

operation,

(Sequencer setting )

Note :

Coordinate system cannot be set by manual

operation, when parameter #6011 DO = 1 [when the

tool coordinate memory number follows the last two

digits of T**$$I.

2.6.5,5 Timing of Coordinate System Setting under

the Automatic Mode

Under the automatic mode, coordinate system

setting is performed when the turret is called up

by the T code.

The tool coordinate memory

number uses the turret number commanded on the

command screen or the offset number for

operation.

Unlike the conventional offset method, the T

code command in the coordinate system setting

specification is given as follows.

The setting of parameter #6011 DO decides

whether to set the tool coordinate memory number

at the front two digits of T4-digit, or at the last

two digits of the T4-digit,

The execution of the coordinate system

setting differs as follows, by the parameter

setting.

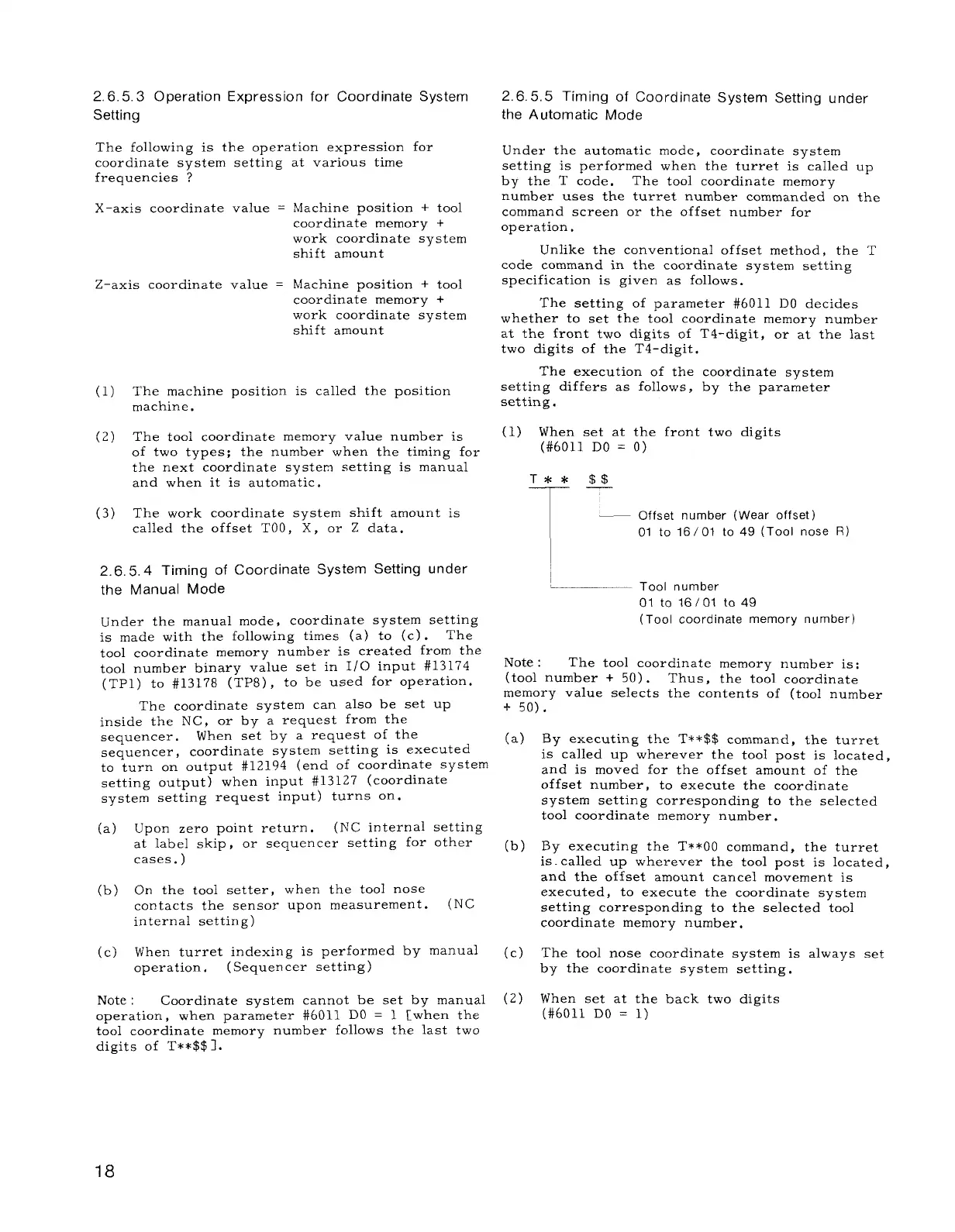

(1) When set at the front two digits

(#6011 DO = O)

T** $$

T—

~

— Offset number (Wear offset)

01 to 16/01 to 49 (Tool nose R)

,_

—— Tool number

01 to 16/01 to 49

(Tool coordinate memory number)

Note :

The tool coordinate memory number is:

(tool number + 50).

Thus, the tool coordinate

memory value selects the contents of (tool number

+ 50).

(a)

(b)

(c)

(2)

By executing the T**$$ command, the turret

is called up wherever the tool post is located,

and is moved for the offset amount of the

offset number, to execute the coordinate

system setting corresponding to the selected

tool coordinate memory number.

By executing the T**OO command, the turret

is.called up wherever the tool post is located,

and the offset amount cancel movement is

executed, to execute the coordinate system

setting corresponding to the selected tool

coordinate memory number,

The tool nose coordinate system is always set

by the coordinate system setting.

When set at the back two digits

(#6011 DO = 1)

18

Loading...

Loading...