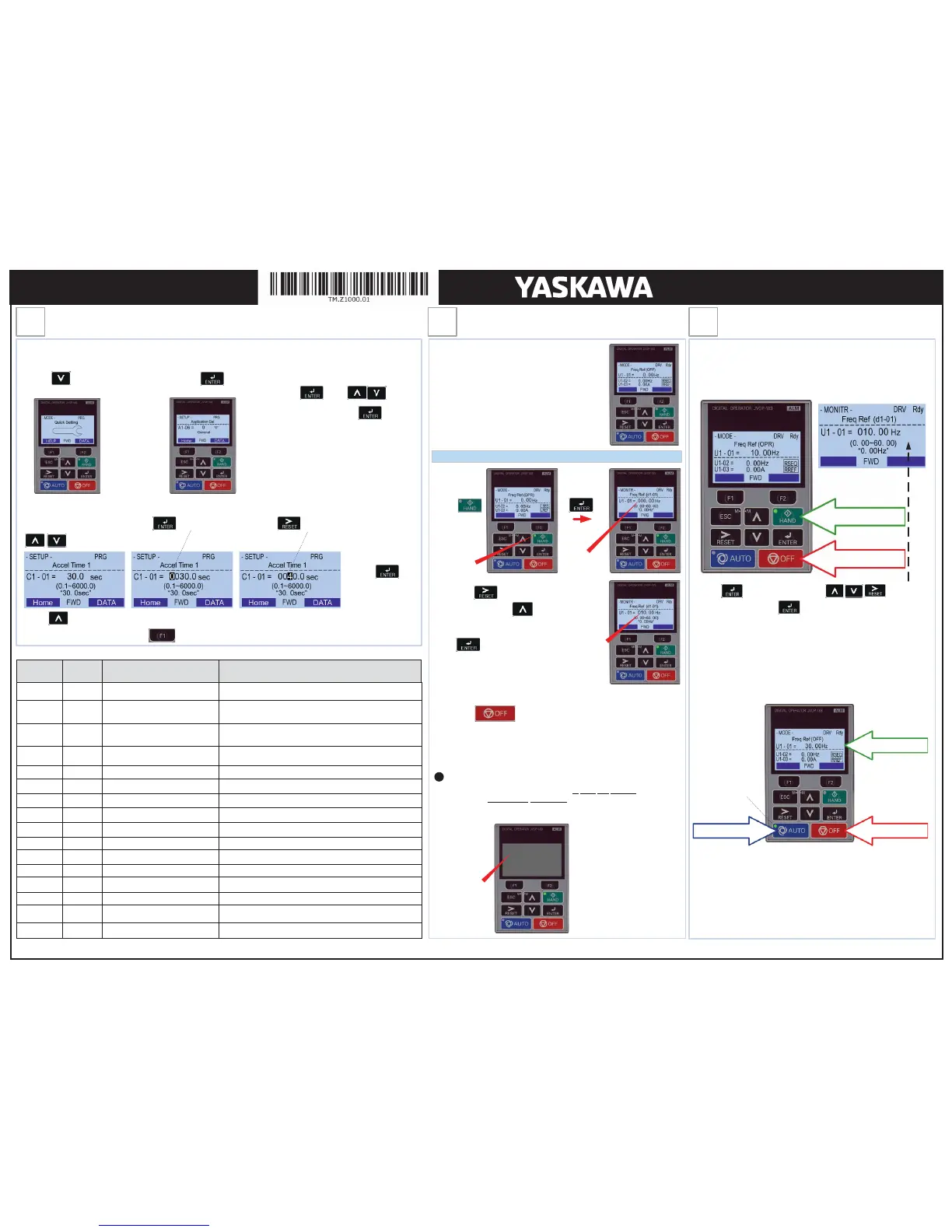

In this step the motor is checked for proper direction

and operation. This test is to be performed solely

from the digital operator. Apply power to the Z1000

after all the electrical connections have been made

and protective covers have been re-attached. At

this point, D

, the Digital

Operator should display as shown in

Use precaution, and refer to

output leads to the motor

(U/T1, V/T2 and W/T3). After the

wiring change, repeat

and recheck motor direction.

After the power has been turned OFF, wait at

least five minutes until the

charge indicator extinguishes

completely before touching any wiring, circuit

boards or components.

DANGER

If motor rotation is not correct, power down the drive, wait five minutes and

swap two motor leads at

the drive output terminals.

!

Next, press to move the cursor one

position to the right and to increase the

frequency reference (d1-01) to 10.00 Hz.

Press to save freq. reference.

The motor should now be operating at low speed

running in the correct forward (clockwise) direction.

Next, press on the Digital Operator.

Digital Operator

turned off.

First Digit

Flashing

Press

Green LED

is blinking.

10.00 Hz

Check Motor Rotation and Direction

Hand / Auto Mode Operation

Page 2 of 2

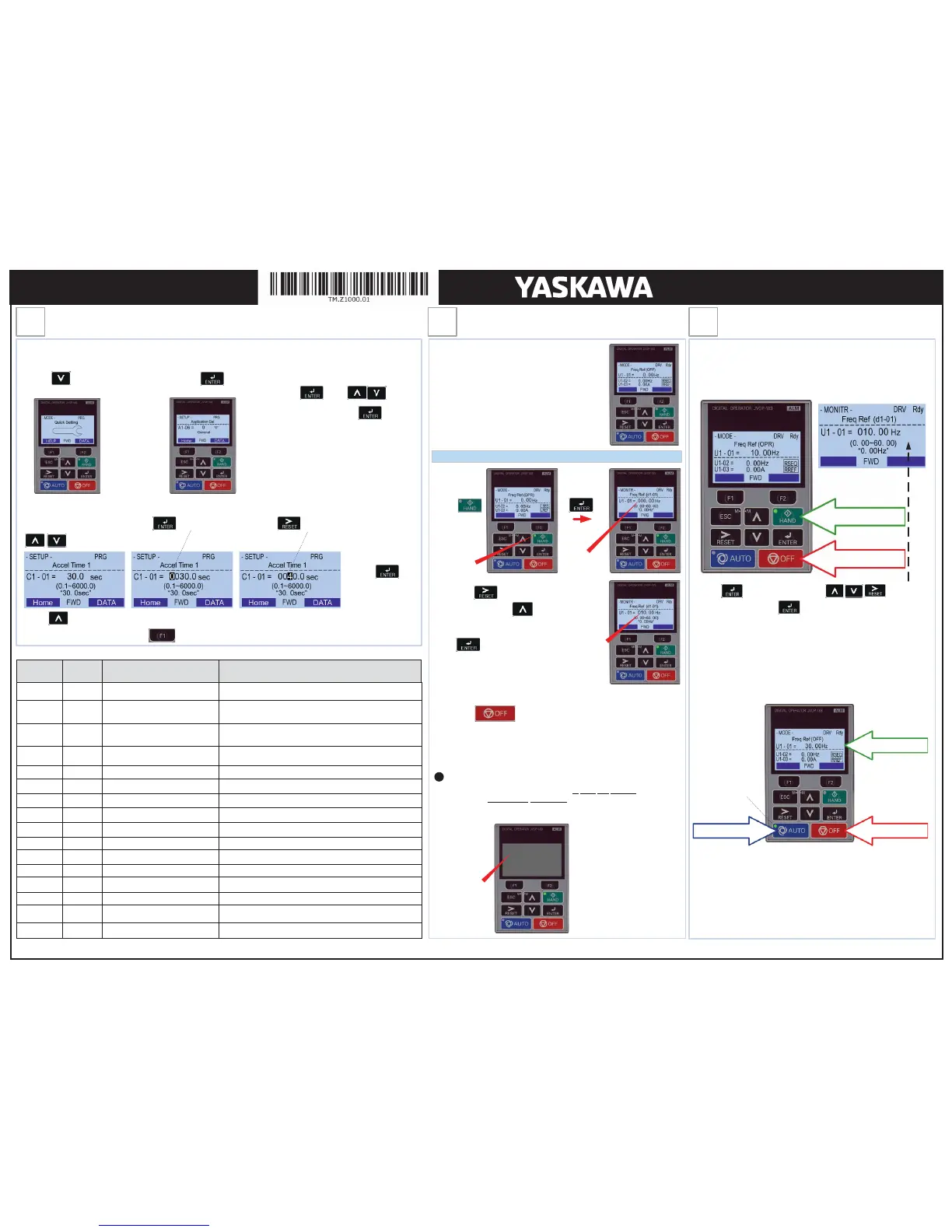

This step shows how to set up the most important parameters using the Z1000 Quick Setup function. Apply power to the Z1000

after all the electrical connections have been made and the terminal cover has been re-attached. At this point D

he digital operator should be reading as shown in

. to the right.

After selecting the Application the Z1000 Quick Setup will display the dedicated application parameters to set up your Z1000

Drive for the selected application. Press to access a parameter, and use to select the digit and use

to change the parameter value.

Press

to save the value.

Press to go to the next parameter to continue the Quick Setup programming.

When Quick Setup is completed press “Home” to exit the Quick Setup menu and go to operation.

Frequently Used Parameters

Press three times until the

digital operator shows the Quick Setting menu.

1.

Press to start the

Quick Setup.

2.

Select Application

3.

Press and use to switch

between applications. Press to select.

Available Applications:

0:

General: Basic Drive Operation

Fan General: Fan Application without PI Control

Fan Application with PI Control

Return Fan with PI Control

Cooing Tower Fan without PI Control

Cooling Tower Fan with PI Control

Pump (Secondary) without PI Control

Pump with PI Control

Parameter

Default

Value

Description Comments

A1-06 0 Application Selection See Application list under step 4.

b1-01 1

Reference Source 1

Speed Control Method

0 = Digital Operator (Adjust Motor Speed from keypad)

1 = Terminals (Speed Pot. / 0 – 10V / 4—20mA)

b1-02 1

Run Source 1 /

Start/Stop Control Method

1 = Terminals (Start/Stop using external contact / switch)

3 = Communication

b1-03 1 Stop Method Selection

0 = Ramp to stop (Motor ramps down at stop command)

1 = Coast to stop (Motor freewheels at stop command)

b5-01 0 PI Mode Selection 0 = Disabled, 1 = Enabled, 3 = Fref + PI

b5-02 2.00 PI Proportional Gain Setting Only active when b5-01 is set to value greater than 0

b5-03 0.5 sec. PI Integral Time Setting Only active when b5-01 is set to value greater than 0

b5-20 1 PI Setpoint Scaling 0 = Hz,1= %, 2 = rpm, 3 = custom (use b5-38, b5-39 and b5-41)

C1-01 30.0 sec. Acceleration Time The time it takes to ramp up from 0 to maximum motor speed.

C1-02 30.0 sec. Deceleration Time The time it takes to ramp down from maximum motor speed to 0.

d2-01 100.0 % Frequency Reference Upper Limit Maximum motor speed allowed (e.g. 100 % = Max rpm)

d2-02 0.0 % Frequency Reference Lower Limit Minimum motor speed allowed (e.g. 100 % = Max rpm)

E1-01 * Input Voltage Setting Motor nameplate voltage

E2-01 * Motor Rated Current Motor nameplate current

H3-09 1 Terminal A2 Signal Level Selection 0 = 0 to 10V, 1 = -10 to 10V, 2 = 4 to 20mA, 3 = 0 to 20mA

H3-10 1 Terminal A2 Function Selection Predefined signals, see Z1000 User Manual

The Z1000 can be operated in HAND mode when the following actions have been

performed:

· All parameters are programmed

· Motor direction has been checked

button to put the Z1000 into AUTO mode.

In AUTO mode the Z1000 is capable of starting or stopping based on the Run

Source Selection setting parameter b1-02. (See Step 3 Select Start/Stop

Control Method)

The Speed Command used in AUTO mode is based on the Reference Source

Selection setting parameter b1-01. (See Step 3 Select Speed Method)

The Z1000 can be operated in AUTO mode when the following actions have been

performed:

· All parameters are programmed

· Motor direction has been checked

· Auto Mode: Reference source selected in parameter b1-01 (See step 3)

· Auto Mode: Run source selected in parameter b1-02 (See Step 3)

Press to access Hand Speed. Use to change

Hand Speed value. Press to save value.

PRESS HAND BUTTON

PRESS TO TURN OFF

PRESS AUTO BUTTON PRESS TO TURN OFF

AUTO REFERENCE

LED is blinking

when AUTO mode

is active but AUTO

Run Command is

not active.

YAI Document Number: TM.Z1000.01 01/20/2016 ©2012-2016 Yaskawa America, Inc. - (800) YASKAWA (927-5292) Fax (847) 887-7310 DrivesHelpDesk@yaskawa.com www.yaskawa.com

Z1000 AC Drive

Quick Start Procedure

Loading...

Loading...