What to do if YASKAWA P1000 Controller shows option communication error?

- GGarrett EstradaJul 26, 2025

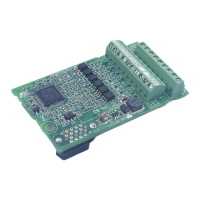

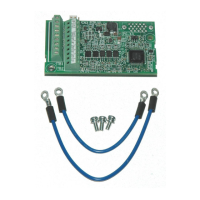

If the YASKAWA Controller displays an option communication error, there are several possible causes and solutions: * **No signal from PLC:** Check for faulty wiring. * **Faulty wiring or short circuit:** Correct the wiring. * **Communication data error due to noise:** Use surge absorbers. * **Damaged option card:** If wiring is correct and the error persists, replace the option card. * **Improperly connected option card:** Reinstall the option card.