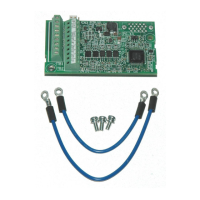

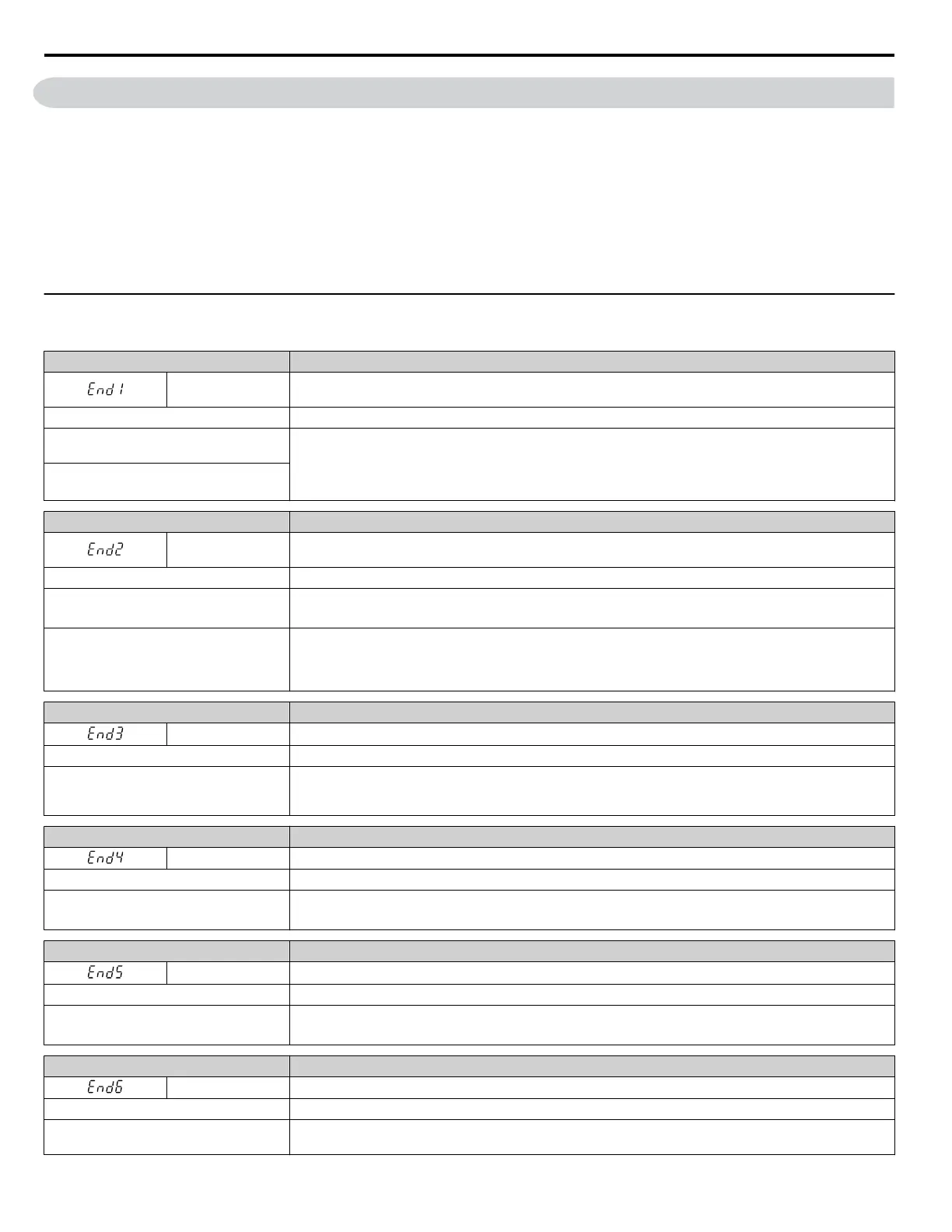

5.5 Auto-Tuning Fault Detection

Auto-Tuning faults in this section are displayed on the digital operator and will cause the motor to coast to a stop. Auto-Tuning

faults do not trigger a multi-function digital output set for fault or alarm output.

An Endo error on the digital operator display indicates Auto-Tuning has successfully completed with discrepancies in the

calculations. Check the cause of the Endo error using the tables in this section and perform Auto-Tuning again after fixing

the cause.

The drive may be used in the application if no cause can be identified despite the existence of an Endo error.

An Ero error indicates that Auto-Tuning has not completed successfully. Check for the cause of the error using the tables in

this section, and perform Auto-Tuning again after fixing the cause.

u

Auto-Tuning Codes, Causes, and Possible Solutions

Table 5.5 Auto-Tuning Codes, Causes, and Possible Solutions

Digital Operator Display Error Name

End1

Excessive V/f Setting (detected only during Rotational Auto-Tuning and displayed after Auto-Tuning is

complete)

Cause Possible Solutions

The torque reference exceeded 20% during

Auto-Tuning.

• Prior to Auto-Tuning, verify the information on the motor nameplate.

• Enter proper values from motor nameplate to parameters T1-02 and T1-04 and repeat Auto-Tuning.

• If possible, disconnect the motor from the load and perform Auto-Tuning. If the load cannot be uncoupled,

use the current Auto-Tuning results.

The results from Auto-Tuning the no-load

current exceeded 80%.

Digital Operator Display Error Name

End2

Motor Iron-Core Saturation Coefficient (detected only during Rotational Auto-Tuning and displayed after

Auto-Tuning is complete)

Cause Possible Solutions

Motor data entered during Auto-Tuning

was incorrect.

• Make sure the data entered to the T1 parameters match the information written on the motor nameplate.

• Restart Auto-Tuning and enter the correct information.

Results from Auto-Tuning are outside the

parameter setting range, assigning the iron-

core saturation coefficients (E2-07 and

E2-08) to temporary values.

• Check and correct faulty motor wiring.

• Disconnect the motor from machine and perform Rotational Auto-Tuning.

Digital Operator Display Error Name

End3 Rated Current Setting Alarm (displayed after Auto-Tuning is complete)

Cause Possible Solutions

The correct current rating printed on the

motor nameplate was not entered into

T1-04.

• Check the setting of parameter T1-04.

• Check the motor data and repeat Auto-Tuning.

Digital Operator Display Error Name

End4 Adjusted Slip Calculation Error

Cause Possible Solutions

The calculated slip is outside the allowable

range.

• Make sure the data entered for Auto-Tuning is correct.

• If possible, perform Rotational Auto-Tuning. If not possible, perform Stationary Auto-Tuning 2.

Digital Operator Display Error Name

End5 Resistance Tuning Error

Cause Possible Solutions

The calculated resistance value is outside

the allowable range.

• Double-check the data entered for the Auto-Tuning process.

• Check the motor and motor cable connection for faults.

Digital Operator Display Error Name

End6 Leakage Inductance Alarm

Cause Possible Solutions

The calculated leakage inductance value is

outside the allowable range.

Double-check the data entered for the Auto-Tuning process.

5.5 Auto-Tuning Fault Detection

150

YASKAWA ELECTRIC TOEP YAIP1U 01B YASKAWA AC Drive - P1000 Quick Start Guide

Loading...

Loading...